Method for grinding cement admixture and grinding aid for cement admixture

A technology of admixtures and grinding aids, applied in the field of cement admixtures grinding aids, can solve problems such as inability to biochemically process, waste of resources, high energy consumption, etc., achieve comprehensive utilization of low-cost resources, realize comprehensive utilization of resources, and improve material efficiency. The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment SA1

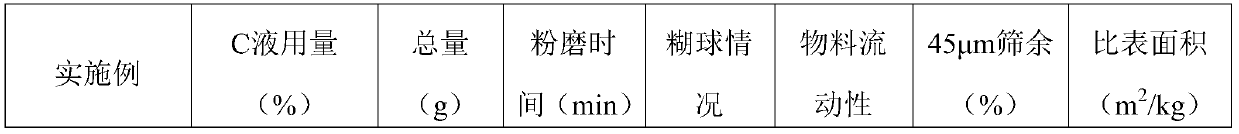

[0062] Examples SA1-SA5

[0063] Liquid C was mixed with slag (Masteel Group) and fly ash (Anhui Lu'an Power Plant) in different weight ratios for grinding treatment. The specific conditions and results are shown in Table 1 and Table 2, respectively.

[0064] Table 1: Slag grinding conditions and results of Comparative Example DA1 and Examples SA1-SA5

[0065]

[0066]

[0067] Table 2: Fly Ash Grinding Conditions and Results of Comparative Example DA1 and Examples SA1-SA5

[0068]

[0069] As can be seen from the results in Table 1-2: 1. After adding liquid C, the fluidity of all materials is improved; 2. After adding liquid C, the 45 micron sieve residue of all materials decreases; 3. After adding liquid C, the embodiment The specific surface area of SA1-SA5 materials all increases, but excessive addition will greatly improve the fluidity of the material, reduce the friction between the material and the grinding medium, and make the material unable to be effectiv...

Embodiment SB1

[0072] The liquid C was used as a grinding aid and mixed with slag and fly ash at a ratio of 0.1% by weight for grinding treatment. The specific conditions and results are shown in Table 3-4.

Embodiment SB2

[0074] Add sodium hydroxide to liquid C to adjust the pH value to 10, then use it as a grinding aid, and mix slag and fly ash in a proportion of 0.1% by weight for grinding treatment. The specific conditions and results are shown in Table 3-4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com