A kind of cement raw material additive and its application and cement production process

A technology for cement raw meal and additives is applied in the field of cement production technology to achieve comprehensive utilization of low-cost resources, good grinding aid effect, and the effect of increasing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0047] In the second embodiment, the application includes: mixing cement raw meal additives into cement raw meal raw materials while they are being ground (that is, mixing is completed in the grinding treatment device), to obtain cement raw meal mixed with cement raw meal additives. feed product.

[0048] In a third embodiment, the application includes: mixing the ground cement raw meal raw materials with cement raw meal additives (such as in the selection of cement raw meal powder, in the cement raw meal storehouse or before entering the preheater bucket elevator), to obtain a cement raw meal product mixed with cement raw meal additives.

[0049] In the above embodiments, the pulverization treatment can be carried out in a conventional device (such as a raw material mill). Preferably, the application is realized in the first embodiment, that is, the mixing of the cement raw meal raw material and the cement raw meal additive is completed before the grinding treatment.

[0050]...

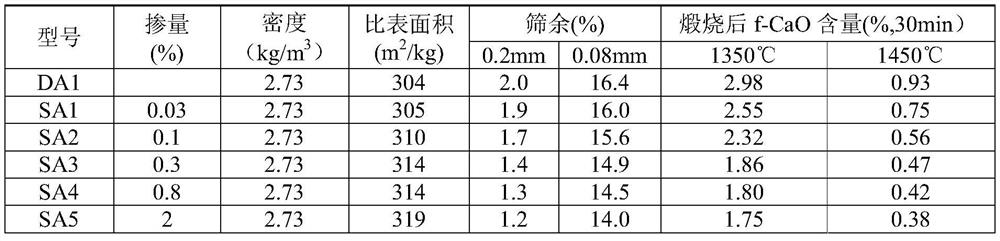

Embodiment SA1

[0070] The liquid A (100 parts by weight) was mixed with cement raw material in a ratio of 0.03 weight % for grinding and calcining. The specific conditions and results are shown in Table 1.

Embodiment SA2

[0072] The liquid A (100 parts by weight) was mixed with cement raw material at a ratio of 0.1% by weight for grinding and calcining. The specific conditions and results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com