Steel slag grinding aid and preparation method thereof

A grinding aid and steel slag technology, applied in the field of chlorine-free grinding aids, can solve the problems of low utilization rate of steel slag, poor safety, poor activity of steel slag products, etc., and achieves excellent grinding aid effect, improved safety and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

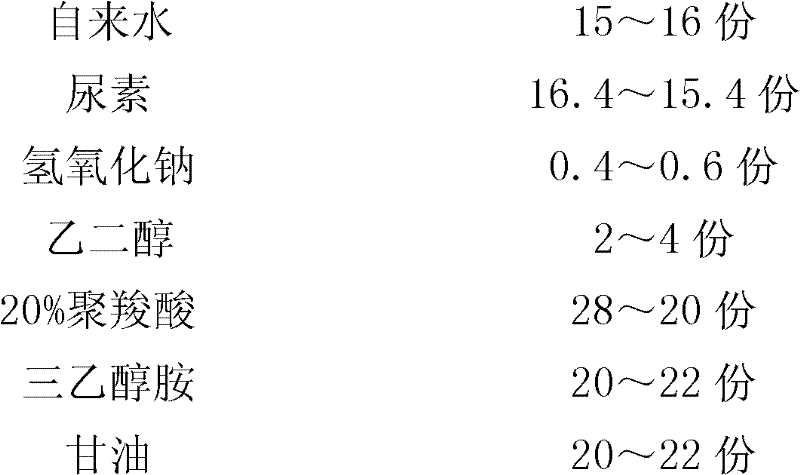

[0014] The steel slag grinding aid comprises the following raw material components in parts by mass:

[0015]

[0016] At room temperature of 25°C, according to the above ratio, first dissolve urea and sodium hydroxide in tap water at 40°C, and remove the precipitate after standing for precipitation to obtain a clear solution; then ethylene glycol, 20% polycarboxylic acid, Triethanolamine and glycerin are sequentially added to the above clear solution and stirred evenly.

[0017] The steel slag grinding aid prepared above is 1.66 tons, the steel slag is 830 tons after magnetic separation in Angang, and the steel slag powder is produced by a ball mill with a diameter of 2.2×7.5 meters, and the output is increased by about 30%. The specific area of steel slag powder: 500~600m 2 / kg, the strength increased by 3-5mPa.

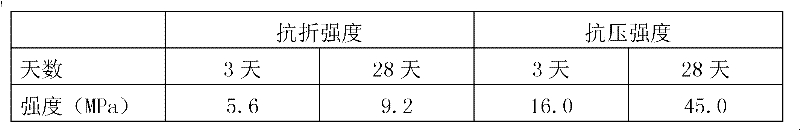

[0018] The steel slag powder prepared above is used to produce cement, the strength grade is 32.5 grade cement, the steel slag powder doping amount is 20-30w...

Embodiment 2

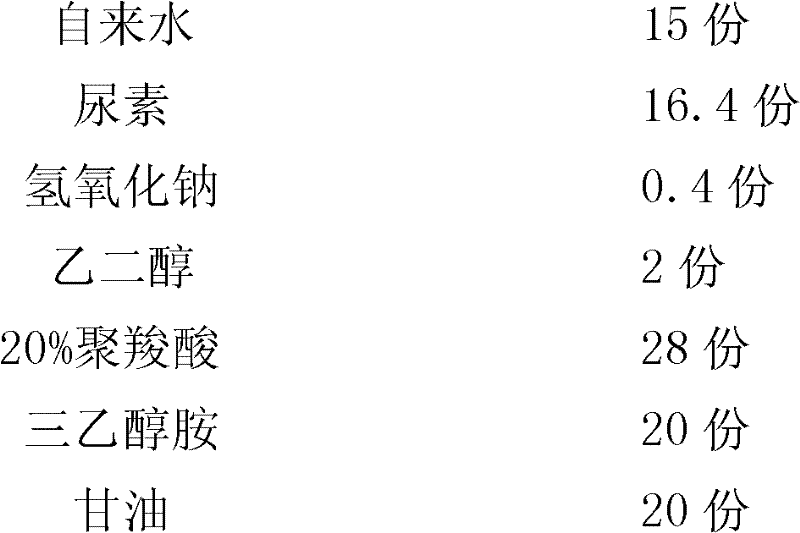

[0021] The steel slag grinding aid comprises the following raw material components in parts by mass:

[0022]

[0023] At room temperature of 25°C, according to the above ratio, first dissolve urea and sodium hydroxide in tap water at 40°C, and remove the precipitate after standing for precipitation to obtain a clear solution; then ethylene glycol, 20% polycarboxylic acid, Triethanolamine and glycerin are sequentially added to the above clear solution and stirred evenly.

[0024] The steel slag grinding aid prepared above is 1.66 tons, the steel slag is 830 tons after magnetic separation in Angang, and the steel slag powder is produced by a ball mill with a diameter of 2.2×7.5 meters, and the output is increased by about 30%. The specific area of steel slag powder: 500~600m 2 / kg, the strength increased by 3-5mPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com