Activating grinding aid for steel slag micro-powder, and preparation method thereof

A technology of steel slag micropowder and grinding aid, which is applied in the field of additives, can solve the problems that the 28-day activity index of steel slag micropowder is not improved and improved, the effect of improving the activity of steel slag micropowder is not good, and the effect is not obvious, and the process of measuring and adding is cumbersome. , Excellent grinding aid effect and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 35 parts by weight of formamide, 30 parts by weight of diethanol isopropanolamine (DEIPA), and 14.8 parts by weight of N,N,N',N'-tetrakis(2-hydroxyethyl)ethylenediamine (THEEDA) into 20 parts by weight The parts by weight of water are mixed and stirred, and then 0.2 part by weight of tributyl phosphate (TNBP) and 0.1 part by weight of triisobutyl phosphate (TIBP) are added to obtain an activated grinding aid.

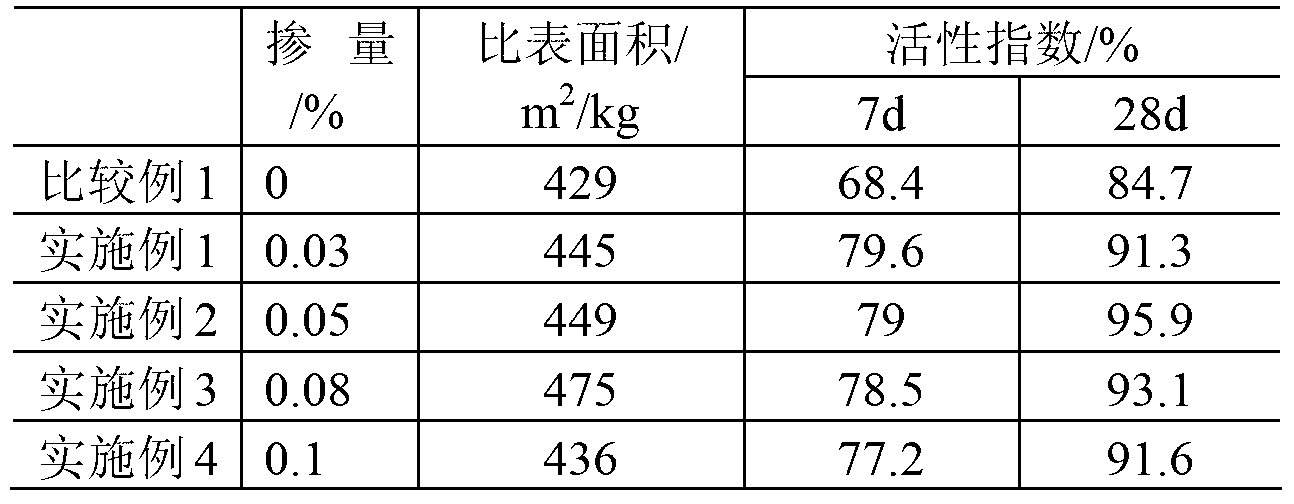

[0026] According to the method of Comparative Example 1, 0.03% of the activated grinding aid prepared in this example was added to steel slag for small mill grinding, and the measurement results of the material after grinding are shown in Table 1.

Embodiment 2

[0028] Take 37.8 parts by weight of dimethylamide (DMF), 7 parts by weight of N,N-bis(2-hydroxypropyl)-N-(hydroxyethyl)amine (EDIPA), 5 parts by weight of diethanol isopropanolamine (DEIPA) Parts by weight, 3 parts by weight of triisopropanolamine, 12 parts by weight of N, N, N', N'-tetrakis (2-hydroxypropyl) ethylenediamine (THPEDA) phosphate, are successively dropped into 30 parts by weight of water and mixed, After stirring, 0.2 parts by weight of a defoamer triisobutyl phosphate (TIBP) was added to obtain an activated grinding aid.

[0029] According to the method of Comparative Example 1, 0.05% of the activated grinding aid prepared in this example was added to steel slag for small mill grinding, and the measurement results of the material after grinding are shown in Table 1.

Embodiment 3

[0031] Take 21 parts by weight of formamide, 3 parts by weight of acetamide, 5 parts by weight of diethanol isopropanolamine (DEIPA), 1.85 parts by weight of triisopropanolamine, N,N,N',N'-tetrakis(2-hydroxy Propyl) ethylenediamine (THPEDA) acetate 7 parts by weight, THEEDA 2 parts by weight were put into 60 parts by weight of water, mixed and stirred, and then added 0.05 parts by weight of defoamer tributyl phosphate (TNBP), triisobutyl phosphate 0.1 parts by weight of ester (TIBP) to obtain an activated grinding aid.

[0032] According to the method of Comparative Example 1, 0.08% of the activated grinding aid prepared in this example was added to steel slag for small mill grinding, and the measurement results of the material after grinding are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com