Large-volume self-compacting concrete and preparation method thereof

A self-compacting concrete, large-volume technology, applied in the field of concrete engineering, can solve problems such as voiding, uncompacting concrete, cracking durability, etc., and achieve the effects of improving retardation performance, reducing shrinkage, improving durability and later strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

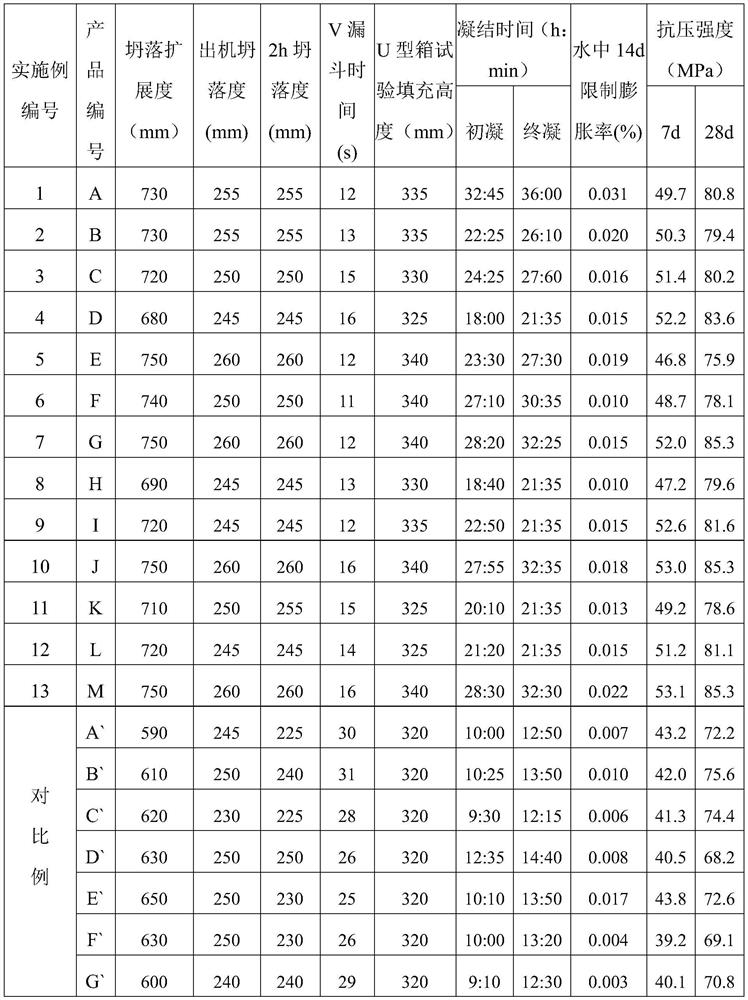

Examples

Embodiment 1

[0038] A large-volume self-compacting concrete, unilateral (m 3 ) Concrete is composed of the following raw materials:

[0039] 580kg of gelling material, 1680kg of aggregate, 12.8kg of compound admixture, and 168kg of water;

[0040] Among them, the cementitious material includes 394kg Portland cement, 70kg ground slag powder (the specific surface area is not less than 800m 2 / kg), 58kg fly ash (Class F Class II), 58kg calcium sulfoaluminate-calcium oxide expansion agent;

[0041] The weight ratio of sand and gravel in the aggregate is 1:1.2, and the sand is sand in Zone II;

[0042] The composite admixture includes 1.2kg high acyl gellan gum, 11.6kg acrylic acid as the main chain and polyether grafted side chain polycarboxylate superplasticizer; wherein the polycarboxylate superplasticizer has a water reducing rate of 22wt%, The average relative molecular mass is 9000-12000, and the relative molecular mass of the grafted side chain is 1100-1300.

[0043] The preparation ...

Embodiment 2

[0048] A large-volume self-compacting concrete, unilateral (m 3 ) Concrete is composed of the following raw materials:

[0049] 600kg of cementitious material, 1660kg of aggregate, 12.0kg of compound admixture, and 172kg of water;

[0050] Among them, the cementitious materials include 388kg of Portland cement (strength grade 42.5), 26kg of finely ground slag powder (specific surface area not less than 800m 2 / kg), 150kg of fly ash (Class F Class II), 36kg of calcium sulfoaluminate-calcium oxide type expansion agent;

[0051] The weight ratio of sand and gravel in the aggregate is 1:1.3, and the sand is sand in Zone II;

[0052] Composite admixtures include 0.6kg high acyl gellan gum, 12.0kg methacrylic acid as the main chain and polyether grafted side chain polycarboxylate superplasticizer; the water reducing rate of polycarboxylate superplasticizer is 14wt %, the average relative molecular mass is 8000-10000, and the relative molecular mass of the grafted side chain is 10...

Embodiment 3

[0058] A large-volume self-compacting concrete, unilateral (m 3 ) Concrete is composed of the following raw materials:

[0059] 579kg of gelling material, 1730kg of aggregate, 10kg of compound admixture, and 166kg of water;

[0060] Among them, the cementitious materials include 335.8kg of ordinary Portland cement (strength grade 42.5), 104.2kg of finely ground slag powder (specific surface area not less than 800m 2 / kg), 92.7kg of fly ash (Class F Class II), 46.3kg of calcium sulfoaluminate-calcium oxide expansion agent;

[0061] The weight ratio of sand and gravel in the aggregate is 1:1.0, and the sand is sand in Zone II;

[0062] Composite admixtures include 0.9kg high acyl gellan gum, 9.1kg polycarboxylate superplasticizer with acrylic acid as the main chain and polyether grafted with side chains; the water reducing rate of polycarboxylate superplasticizer is 17wt%, The average relative molecular mass is 9000-11000, and the relative molecular mass of the grafted side c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Slump spread | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com