Coaxial motor axle assembly with cooling device

A technology of cooling device and electric locomotive, which is applied to the arrangement of cooling combination of power device, control device, power device, etc. It can solve the problems of waste of resources, insufficient sealing, and easy corrosion of parts, so as to prolong the service life, Good cooling effect and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

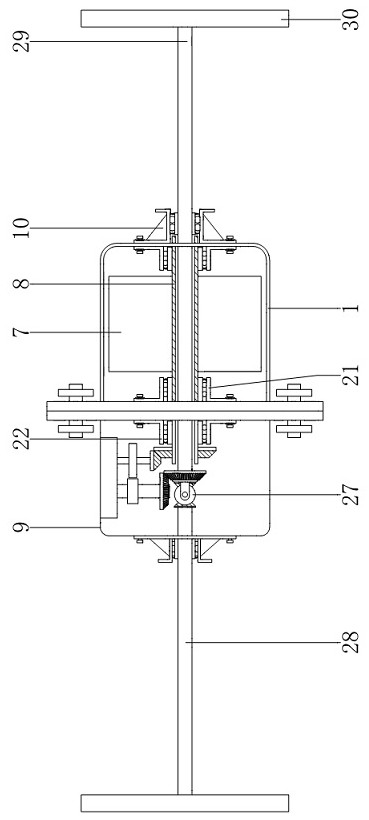

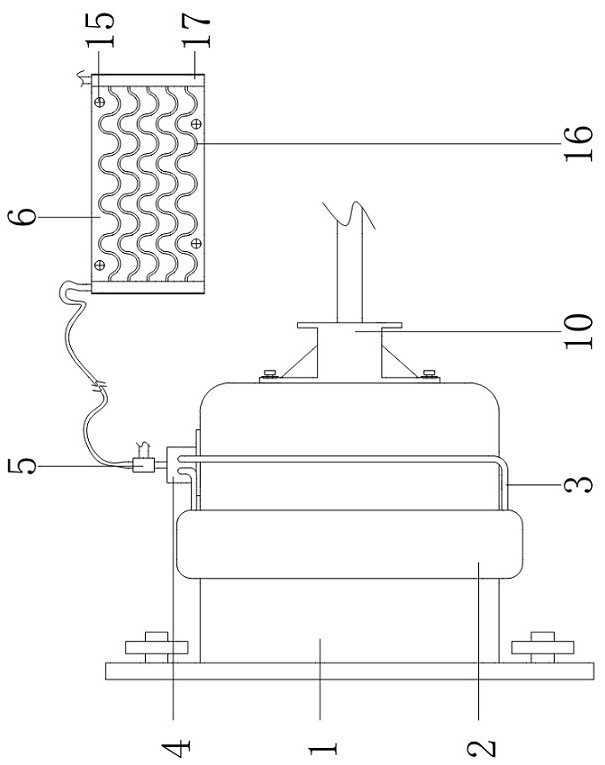

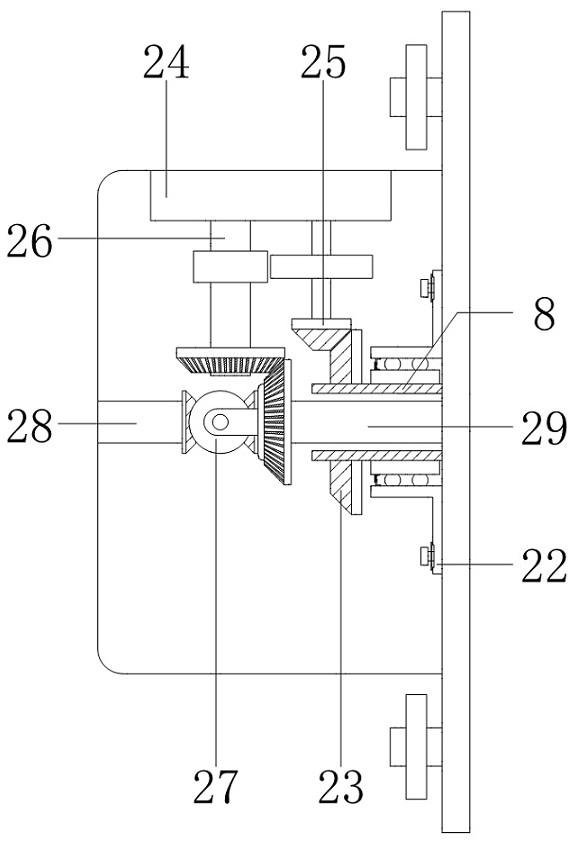

[0025] refer to Figure 1-5 , a coaxial motor axle assembly with a cooling device, including an axle housing 1, the outer surface of the axle housing 1 is sleeved with an annular sealing cover 2, and the annular sealing cover 2 is injected with cooling oil with high heat transfer efficiency (such as propylene glycol ), which can quickly absorb the heat inside the axle housing 1. Compared with the current cooling method of sprinkling water with a spray head outside the axle housing 1, the way of using cooling oil will not cause waste and will not cause corrosion to parts. The outer surface of the annular seal cover 2 is plugged with an oil pipe 3. The oil pipe 3 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com