Method for using continuous paint feeding roller brush

A paint roller and paint technology, applied in construction, building structure and other directions, can solve the problems of polluting indoor floors and construction personnel, waste of raw materials, stability of feeding, affecting the quality of painting, etc., to save raw materials, reduce secondary pollution, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

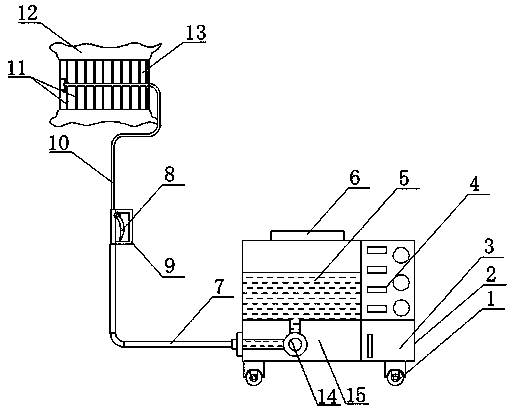

[0023] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention.

[0024] A method for continuously supplying paint roller brushes according to the present invention, comprising the following steps: A, first opening the bin cover, pouring the mixed paint raw materials into the storage bin, and covering the bin cover; B, starting the control box Power supply, so that the power supply in the power supply box supplies power to the pump machine in the pump cabinet, so that the pump machine starts to run, and pumps the paint raw materials in the storage bin into the feed pipe; C, the feed switch set on the control handle, the paint The raw material is pumped into the cavity hall inside the roller brush frame, so that the paint raw material goes out along the cross bar on the top of the roller brush frame along the roller brush frame, so that the paint raw material enters the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com