Long-distance dust-free shotcrete machine

A concrete spraying machine, long-distance technology, applied in the direction of earthwork drilling, shaft lining, tunnel lining, etc., can solve the problems of troublesome cleaning and maintenance, high labor intensity, low spraying efficiency, etc., achieve compact structure, reduce dust pollution, The effect of uniform and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

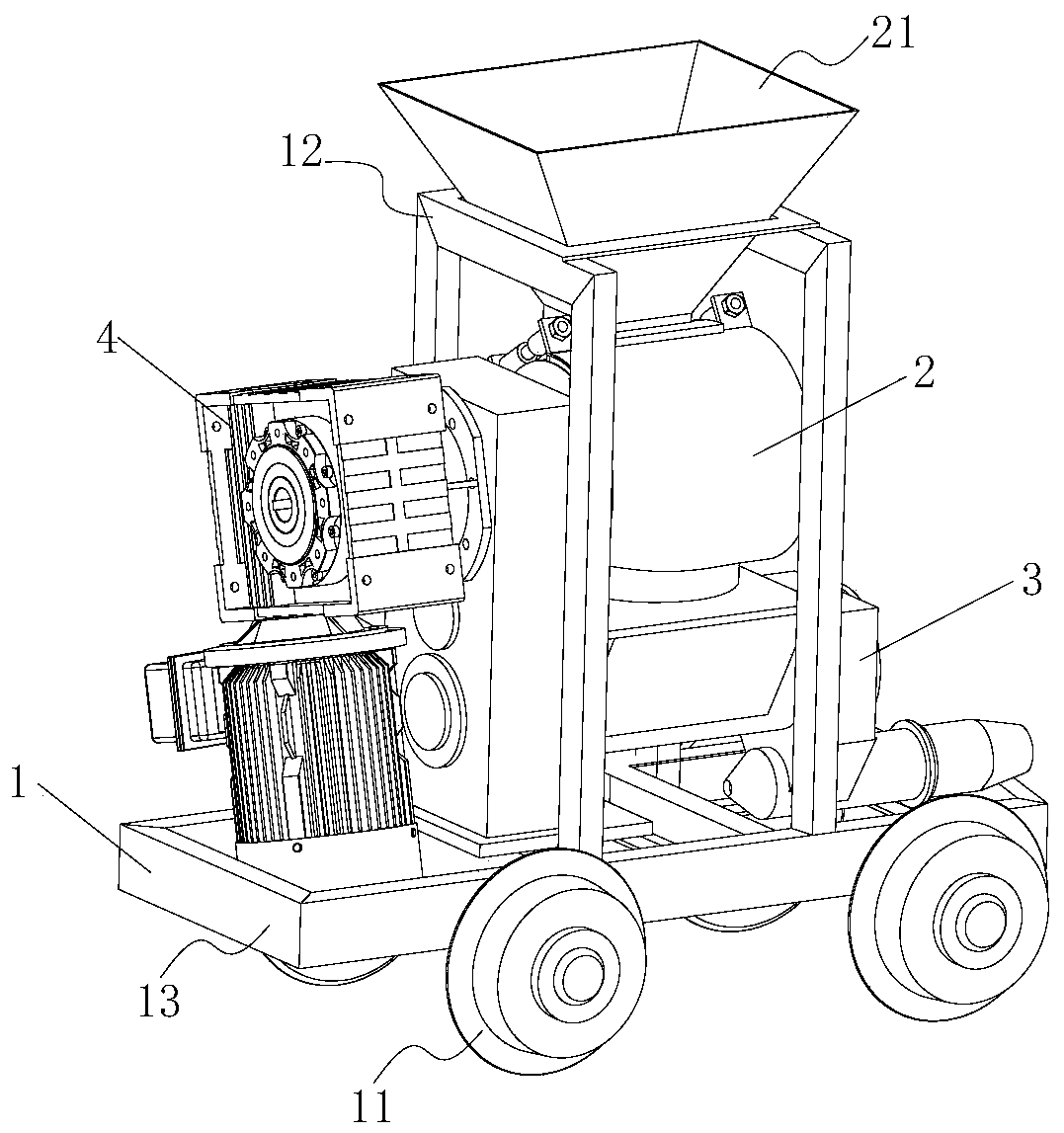

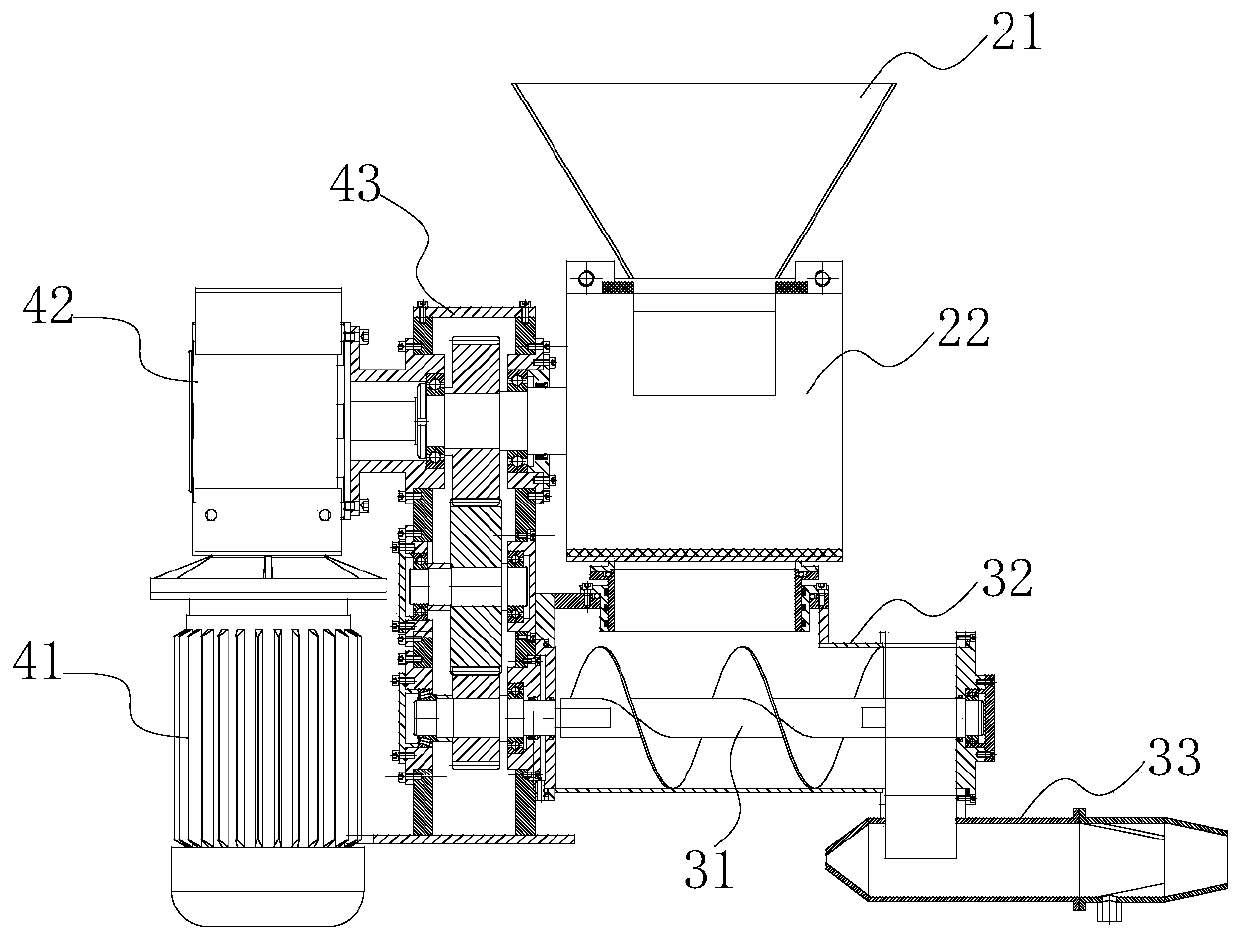

[0039] A specific structure of a long-distance dust-free concrete sprayer includes a body 1 , a feeding mechanism 2 , a spraying mechanism 3 and a driving mechanism 4 . The feeding mechanism 2 improves the feeding method of the existing concrete spraying machine, and the spraying mechanism 3 increases the spraying distance by means of swirl feeding; the feeding mechanism 2 and the spraying mechanism 3 are arranged up and down, so as to facilitate concrete feeding, and the structure is compact. The compensation method realizes the high-strength sealing of the spraying process, thereby increasing the air supply pressure, increasing the conveying distance of concrete, and reducing the dust pollution caused by insufficient sealing.

[0040] The fuselage 1 includes wheels 11 , a vehicle frame 12 and a chassis 13 , the wheels 11 are arranged at the bottom of the chassis 13 , and the vehicle frame 12 is arranged at the top of the chassis 13 . The feeding mechanism 2 includes a hopper...

Embodiment 2

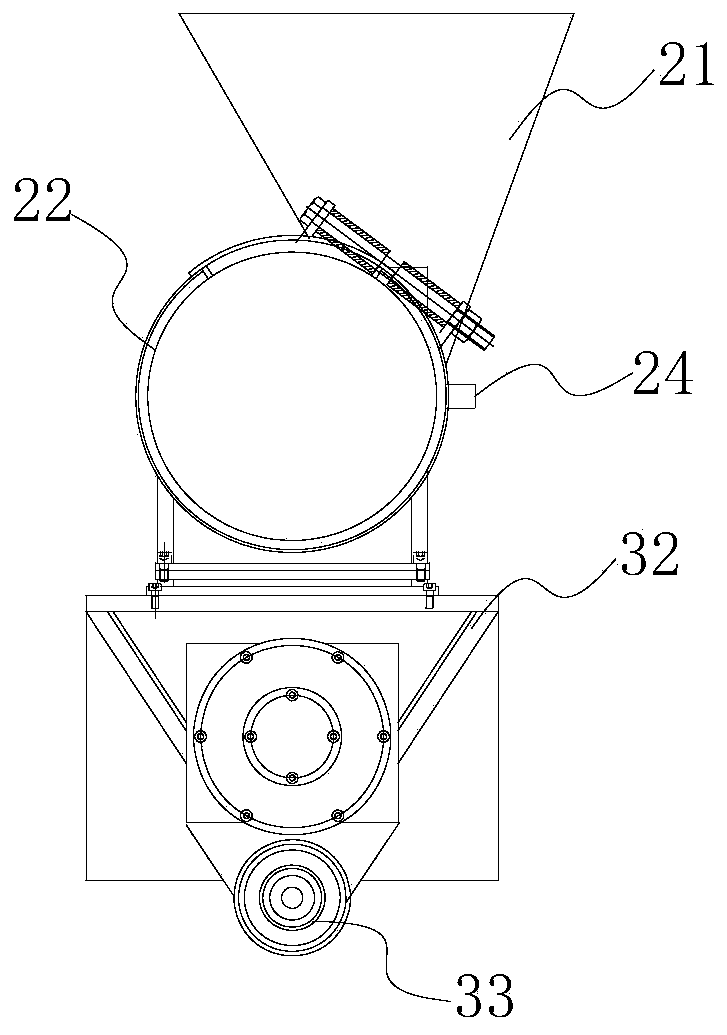

[0044] On the basis of Example 1, this embodiment further improves the feeding mechanism of the concrete sprayer, thereby improving the sealing performance of the feeding mechanism and simplifying the manufacturing process of the feeding mechanism of the concrete sprayer.

[0045] The specific structure of a conical long-distance dust-free concrete sprayer includes a body 1 , a feeding mechanism 2 , a spraying mechanism 3 and a driving mechanism 4 . The feeding mechanism 2 improves the feeding method of the existing concrete spraying machine, improves the sealing performance of the concrete spraying machine, simplifies the manufacturing process of the feeding mechanism part, and facilitates the maintenance and management of the equipment; the spraying mechanism 3 increases the size by swirl feeding. The spraying distance is improved; the feeding mechanism 2 and the spraying mechanism 3 are arranged up and down, so as to facilitate concrete feeding, and the structure is compact,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com