Slaked lime feeding system in water processing system

A water treatment system and slaked lime technology, applied in the field of water treatment, can solve the problems of severe fly ash, lagging pH feedback, untimely adjustment, etc., and achieve the effects of reducing labor intensity of workers, maintaining stable concentration and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

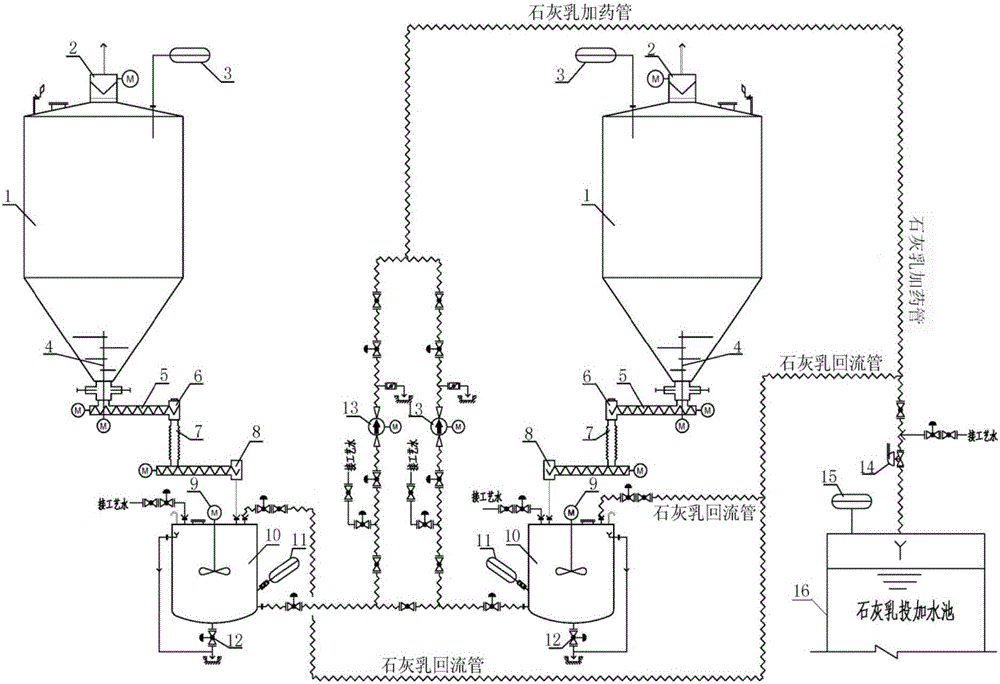

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0026] see figure 1 The slaked lime dosing system in the water treatment system of the present invention comprises a lime powder bin 1, a bag filter 2 and a material level meter 3 are arranged on the lime powder bin 1, and a feeder 4 is arranged at the outlet of the lower end of the lime powder bin 1, The feeder 4 is connected with a metering conveyor 5, the metering conveyor 5 is connected with a doser 8 through a transparent PU pipe 7, and the pipe 7 is equipped with an anti-blocking detector 6, and the doser 8 is connected with lime milk Solution box 10, lime milk solution box 10 is provided with agitator 9, liquid level transmitter 11 and automatic sand discharge valve 12, lime milk solution box 10 is connected with lime milk dosing pool through lime milk dosing pipe, lime milk A pH meter 15 is installed in the dosing pool, and a pneumatic regulating bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com