Pre-sifting vibrating material feeding device

A technology of vibrating feeding and vibrating feeding hopper, which is applied in the fields of filter screen, solid separation, chemical instruments and methods, etc., can solve the problems of unfavorable influence of the machine and failure to sieve, and achieve high efficiency, uniform and stable material feeding, Energy Saving Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail with a pre-screening vibrating feeding device equipped with an XT800 type new crusher.

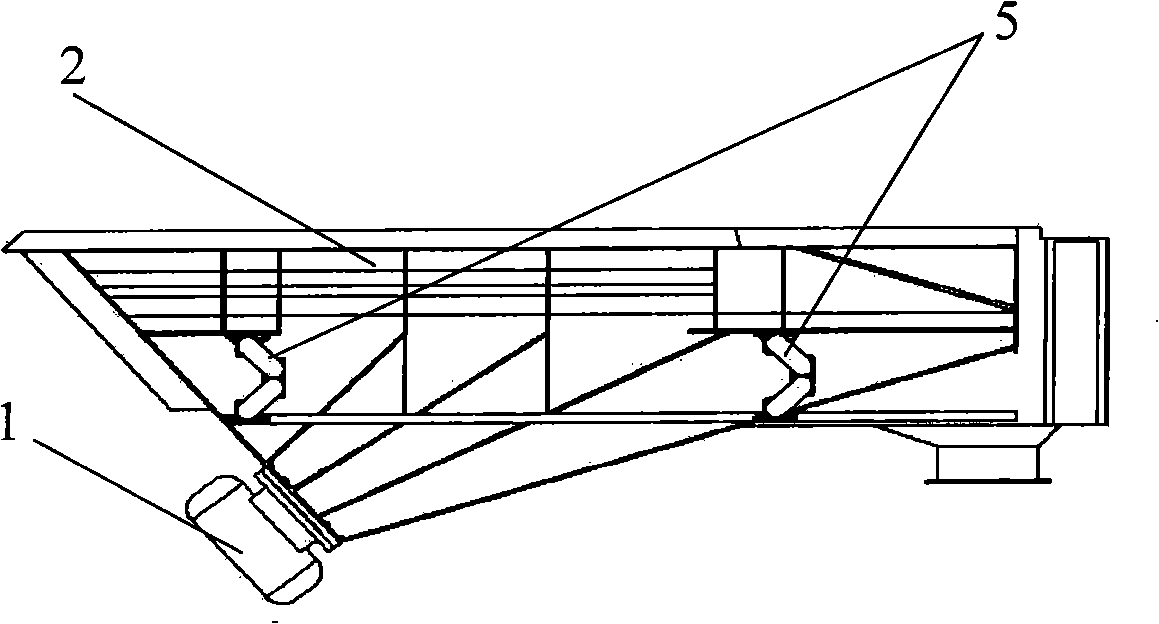

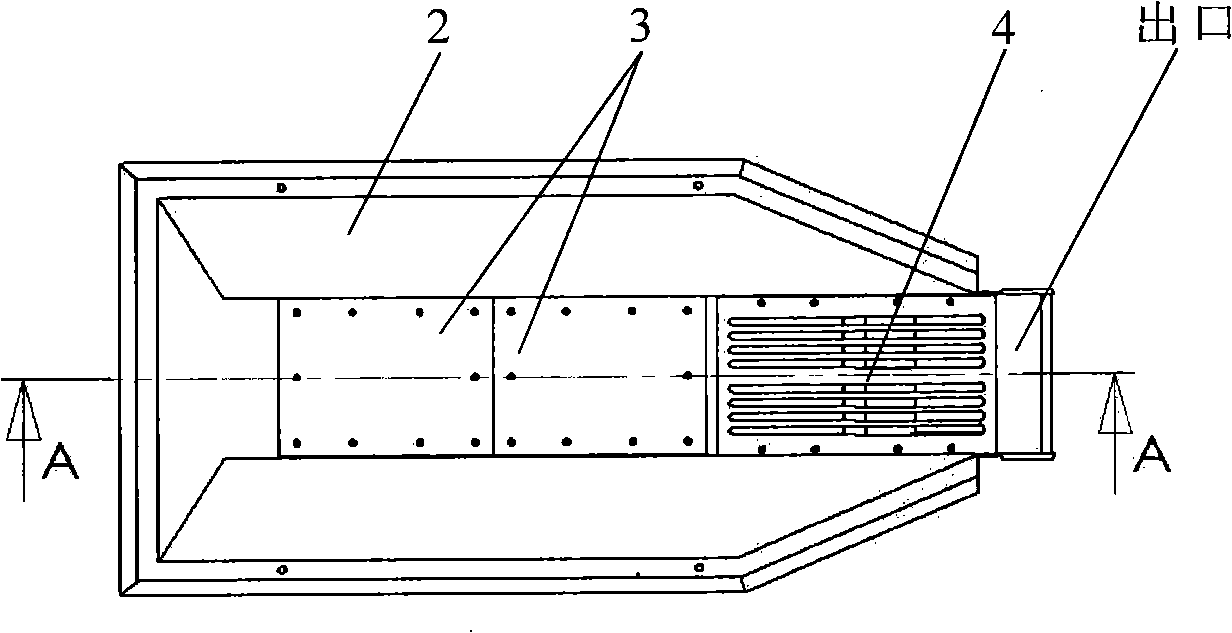

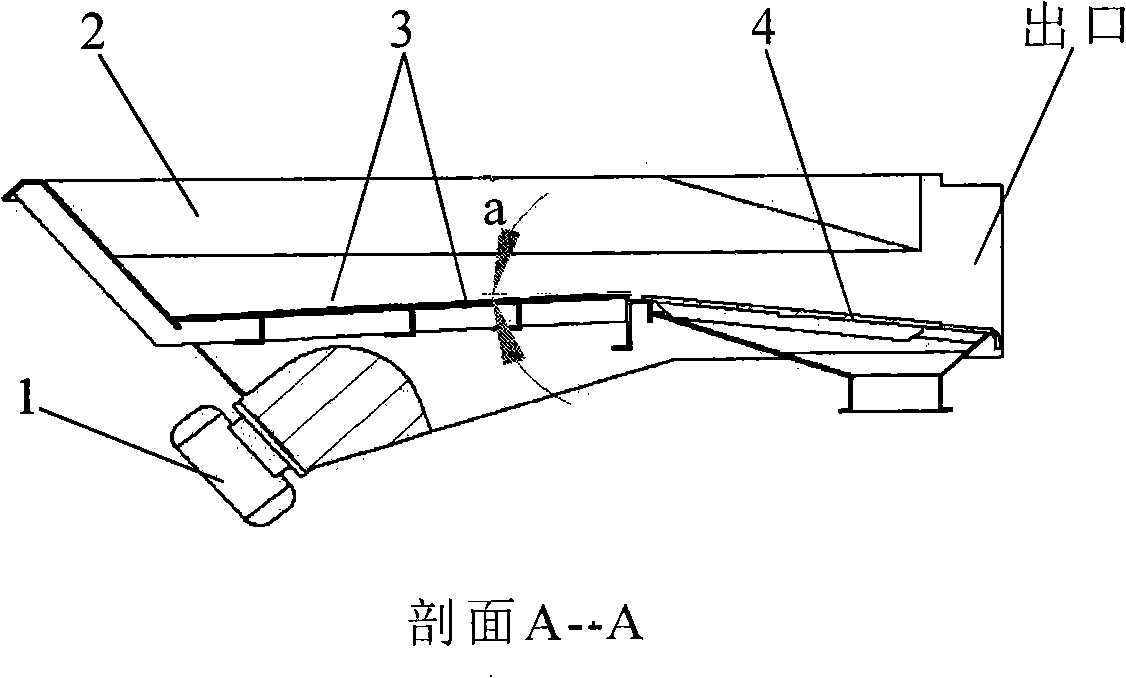

[0012] see figure 1 , XT800 Crusher pre-screening vibration feeding device is composed of frequency modulation vibration motor 1, vibration feeding hopper 2, vibrating bucket bottom plate 3, pre-screening plate 4, and supporting device 5.

[0013] The angle a between the bottom plate of the vibrating hopper 2 and the horizontal plane is 3 to 10 degrees. The bottom plate 3 of the vibrating hopper is made of wear-resistant material and is fixed on the bottom of the vibrating hopper 2 by bolts; On the rear wall of the hopper 2; the pre-screening plate 4 is fixed on the bottom plate at the front end of the vibrating hopper 2 through bolts, and the small material outlet is located below it; the supporting device 5 is fixed on the support seat of the vibrating hopper 2 through bolts under the board. The supporting device 5 is a f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com