Feeding device and method with automatically-adjusted feeding amount

An automatic adjustment and material volume technology, applied in the field of prefabricated panel manufacturing, can solve the problems of slurry easy to hang on the wall, increased friction of rotary feeding valve, slurry leakage, etc., to meet real-time requirements, uniform and stable feeding, The effect of increasing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

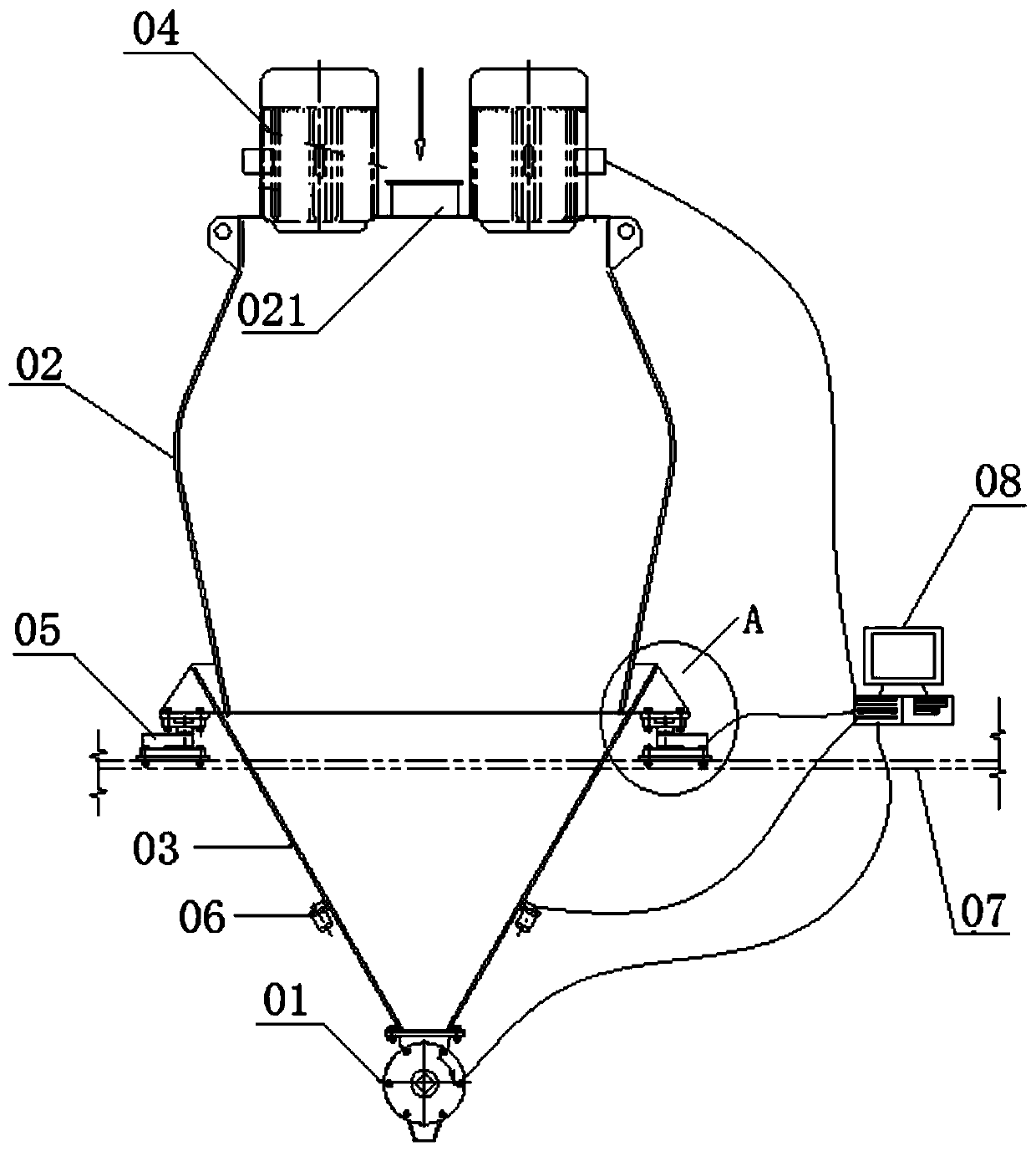

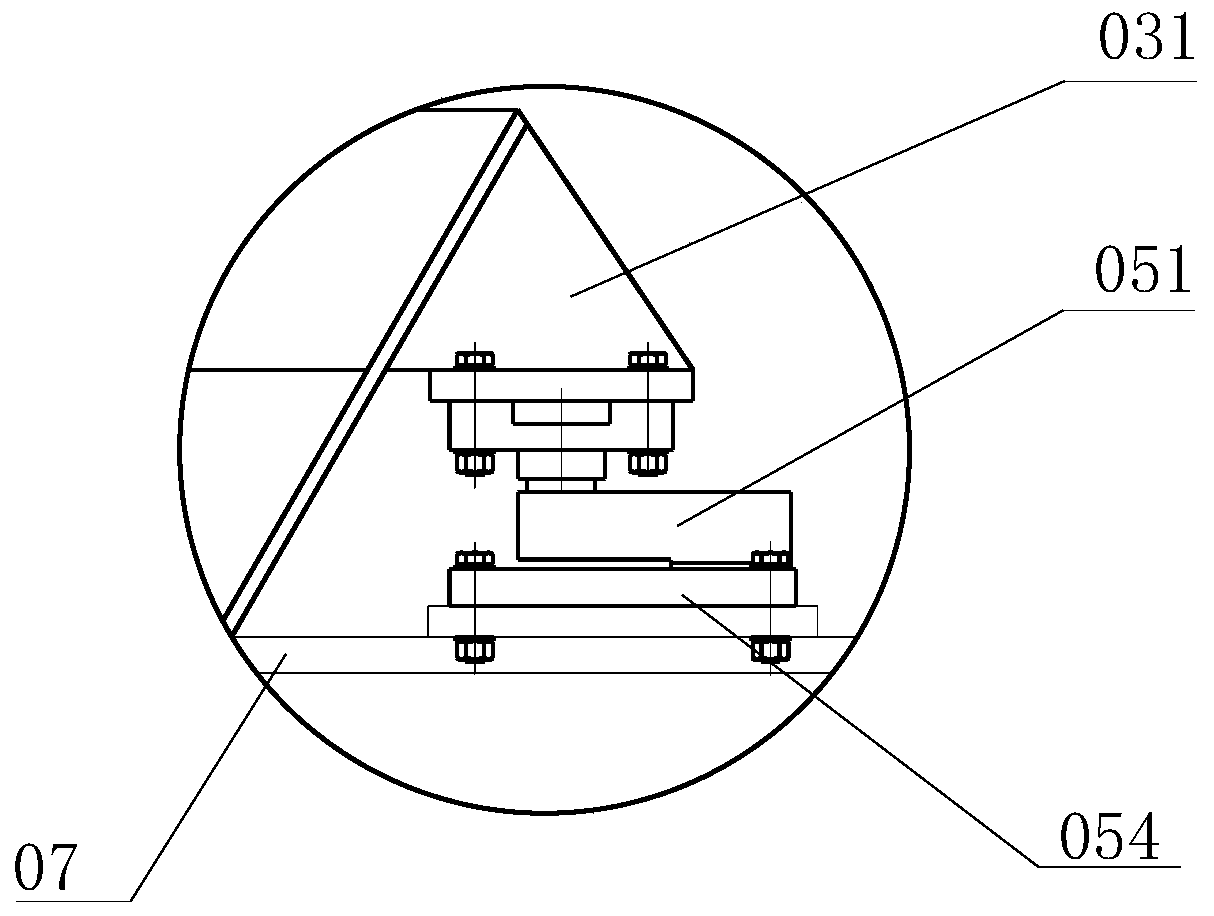

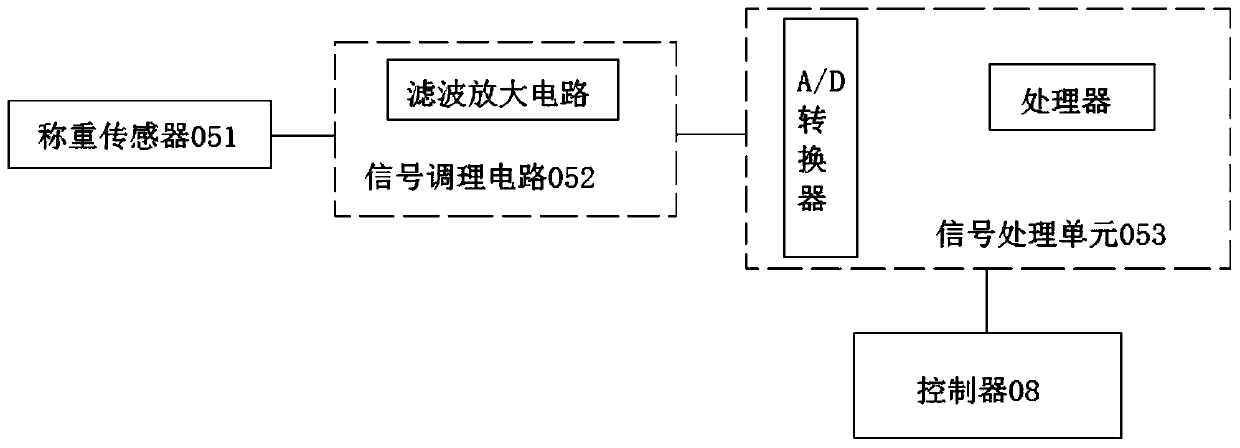

[0048] In order to solve the problems in the existing prefabricated panel production system, such as low degree of automation, uneven feeding volume, easy jamming and easy damage of the feeding valve, and low precision of feeding volume control, etc., the present invention provides a A feeding device and method that can automatically adjust the feeding amount. The method adopts a rotary feeding valve to realize constant-volume feeding, controls the feeding amount by controlling the speed of the impeller flexibly connected to the valve body, and monitors the feeding hopper on-line through a load device. The weight change in the blanking cycle is fed back to the controller. The controller adjusts the impeller speed of the rotary blanking valve online according to the feedback signal to ensure that the blanking amount of a blanking cycle is basically constant, and realizes automatic control according to the material layer thickness of the prefabricated board. The purpose of adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com