Manufacturing method of roller brush capable of supplying coating continuously

A manufacturing method and coating roller technology, applied to the device for coating liquid on the surface, coating, etc., can solve the problems of polluting the indoor ground and construction personnel, waste of raw materials, feeding stability, and affecting the quality of painting, so as to save raw materials , reduce secondary pollution, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

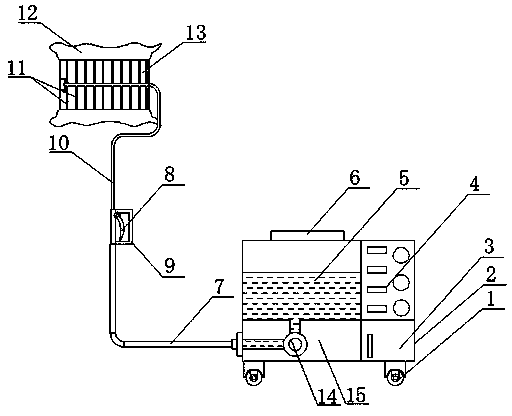

[0021] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention.

[0022] A kind of manufacture method that continuously supplies paint roller brush of the present invention, wherein, comprises the steps:

[0023] A. Select a number of steel angle irons and stainless steel plates and weld them into the body of the feeding truck. The length of the feeding truck is 1.5m, the width is 80cm, and the height is 1.6m. Stainless steel plates are welded on the upper part of the feeding truck body to make a storage box. A circuit control board and a power control button are installed on one side of the material box to make a control box, a mobile power supply is installed on the lower part of the control box to make a power box, and a pump is installed on the lower part of the material storage box to connect the pump and the material storage box to form a control box. The pump cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com