Propulsion type trace feeder

A feeder and push-type technology, which is applied in the field of push-type micro-feeders, can solve the problems of difficult adjustment of feeding amount, high feeding lower limit, uneven feeding, etc., and achieve continuous, stable and uniform feeding and material dispersion The effect of uniform and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

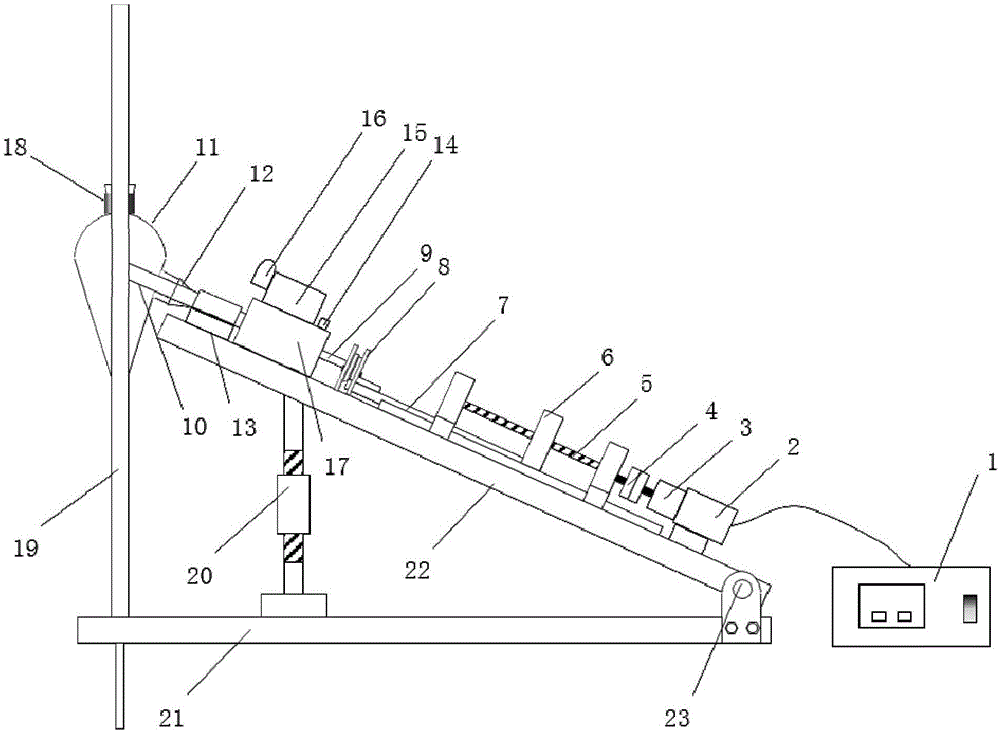

[0019] Specific implementation mode one: as figure 1 As shown, the propulsion type micro-feeder of this embodiment includes a propulsion assembly, a feeding assembly, a support assembly and a vibrating assembly, and the propulsion assembly is installed on the inclined support plate 22 of the support assembly;

[0020] The propulsion assembly includes a control box 1, a stepping motor 2, a reducer 3, a coupling 4, a slide rail 5, a slider 6 and a push rod 7; the control box 1 is electrically connected to the stepping motor 2, and the control box 1 is used to control The speed of the stepping motor 2, the stepping motor 2 is connected with the reducer 3, the reducer 3 is coaxially connected with the slide rail 5 through the coupling 4, the slide block 6 is threaded with the slide rail 5, and one end of the push rod 7 is connected with the slide rail 5 Block 6 is fixedly connected;

[0021] The support assembly includes a blanking bottle fixing clip 18, a screw adjustment suppor...

specific Embodiment approach 2

[0026] Specific implementation mode two: as figure 1 As shown, the bottom of the blanking bottle 11 in this embodiment is in an inverted conical shape, the bottom of the blanking bottle 11 is tapered from top to bottom, and the upper part of the blanking bottle 11 is hemispherical. The conical large-mouth end of the feed bottle 11 constitutes a complete blanking bottle 11 . With such a design, the top of the blanking bottle 11 is the inlet for the material carrier gas, and the bottom is tapered and extends out of a straight pipe section. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: as figure 1 As shown, the hose connector 12 in this embodiment is a silicone hose connector. With such a design, the sealing between the material storage pipe 10 and the blanking bottle 11 can be realized, and the sealing performance is good. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com