Atmosphere-controllable rotary kiln and implementation method thereof

A rotary kiln and atmosphere technology, applied in the field of rotary kiln, can solve problems such as difficulty in improving performance, easy to agglomerate, affect performance, etc., to achieve the effect of preventing safety accidents, avoiding agglomeration, and uniform and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

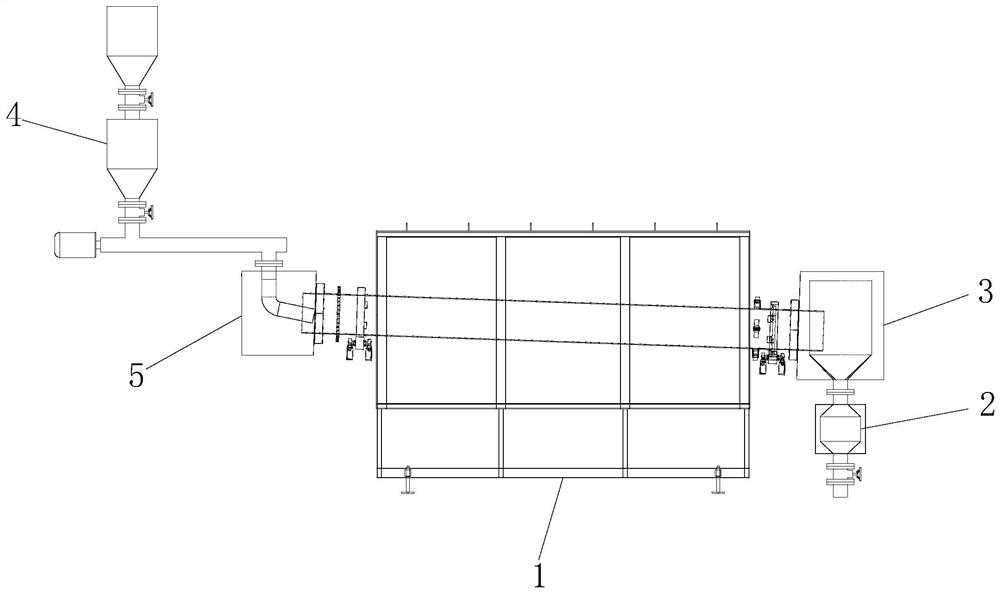

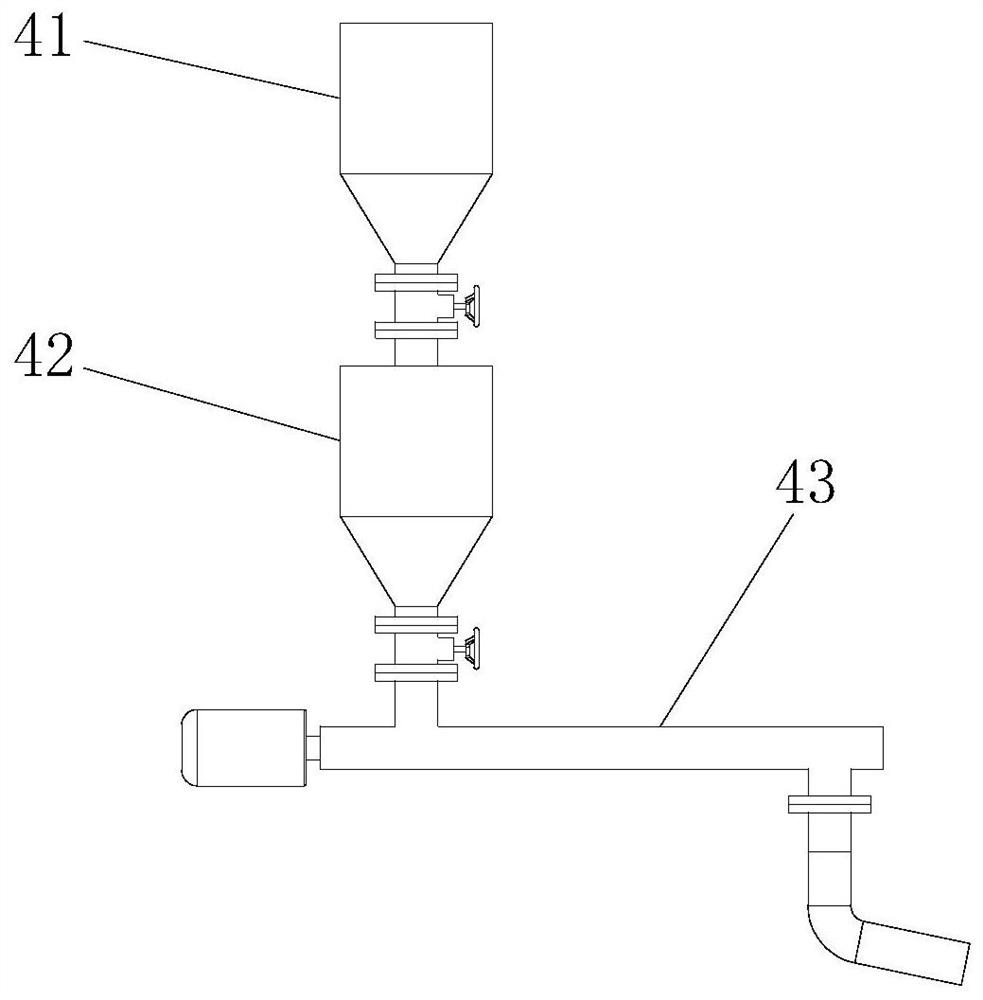

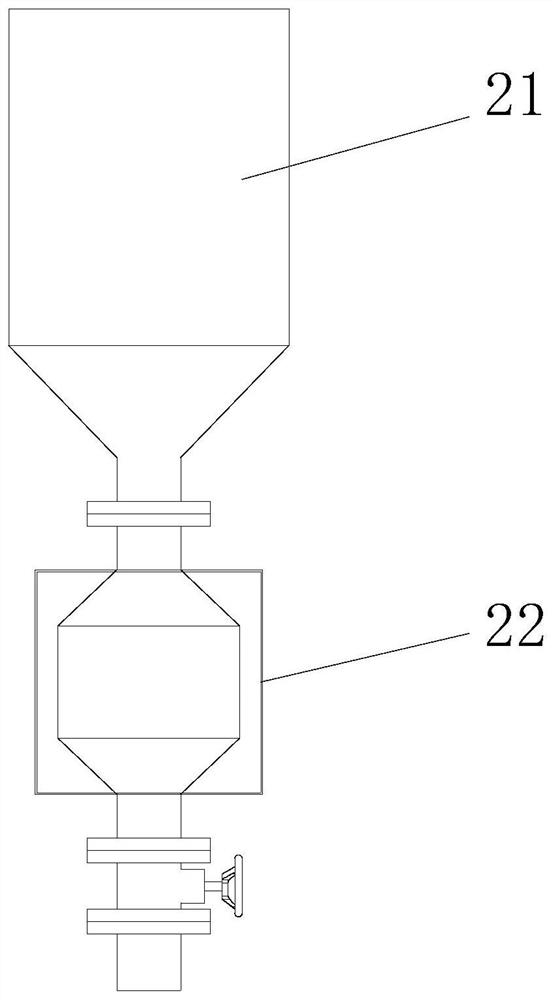

[0037] see Figure 1-7 , the present invention provides the following technical solutions: a controllable atmosphere rotary kiln, including a rotary kiln body 1, the rotary kiln body 1 includes a furnace tube 6, the inner wall of the furnace tube 6 is provided with a stirring bar 7, the stirring bar 7 is a stainless steel component, The feed end of the rotary kiln body 1 is equipped with a feed mechanism 4, the discharge end of the rotary kiln body 1 is equipped with a discharge mechanism 2, and the connection between the rotary kiln body 1 and the feed mechanism 4 is provided with an inert gas protection at the kiln mouth. Device 5, the connection between the rotary kiln body 1 and the discharge mechanism 2 is equipped with an inert gas protection device 3 at the kiln tail.

[0038] Further, the stirring bar 7 has a spiral structure.

[0039] By adopting the above-mentioned technical scheme, the powder material can be stirred indirectly with the rotation of the furnace tube ...

Embodiment 2

[0048] The difference between this embodiment and Embodiment 1 lies in: further, the stirring bar 7 is in the shape of a strip.

[0049] By adopting the above technical scheme, at least three elongated stirring bars are provided.

[0050] Further, the realization method of the controllable atmosphere rotary kiln according to the present invention includes the following steps:

[0051] (1), the material is added from the first feeding bin 41, and enters the inside of the furnace tube 6 through the second feeding bin 42 and the screw feeder 43;

[0052] (2), the reducing gas is inserted from the reducing gas inlet 34, the material is fully contacted with the reducing gas under the stirring of the rotary kiln body 1, and reacts, and the waste gas produced is discharged from the gas outlet 54;

[0053] (3), the material after the completion of the reaction enters the discharge bin 21, and is discharged after being cooled by the cooling tank 22;

[0054] (4), during the reaction,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com