Continuous paint feeding roller brush

A paint roller and material feeding technology, which is applied in the direction of construction and building construction, can solve the problems of polluting indoor ground and construction personnel, waste of raw materials, feeding stability, and low work efficiency, so as to save raw materials and reduce secondary pollution , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

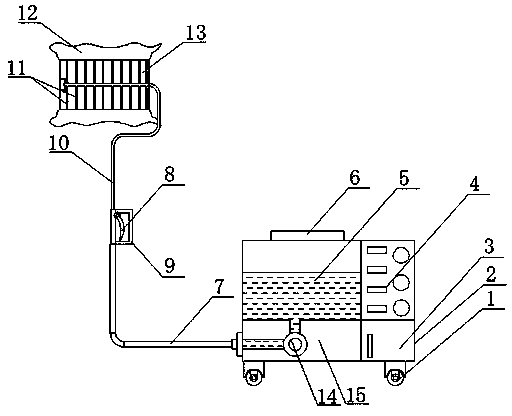

[0018] The present invention will be described below in conjunction with the accompanying drawings. figure 1 It is a structural schematic diagram of the present invention.

[0019] The present invention is a roller brush for continuously supplying paint, comprising a traveling wheel 1, a feeding cart 2, a feeding pipe 7, a feeding switch 8, a handle 9, a roller brush holder 10 and a brush 12, wherein the bottom of the feeding cart 2 is arranged There is a walking wheel 1, and the bottom of the feeding car 2 is welded and fixed, and the lower part of the feeding car 2 is provided with a pump case 15, and a pump machine 14 is welded and fixed inside the pump case 15, and the lower part of the feeding car 2 is adjacent to the side of the pump case 15 A power supply box 3 is provided, and a mobile power supply is provided in the power supply box 3. A control box 4 is provided on the upper part of the power supply box 3. A storage bin 5 is provided on the side adjacent to the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com