Laser marking system

a laser marking and indicia technology, applied in the field of laser marking systems, can solve the problems of insufficient repositioning to form complete characters or graphics, limited accuracy of known embodiments of this system, etc., and achieve the effect of increasing immunity to vibrational misalignmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

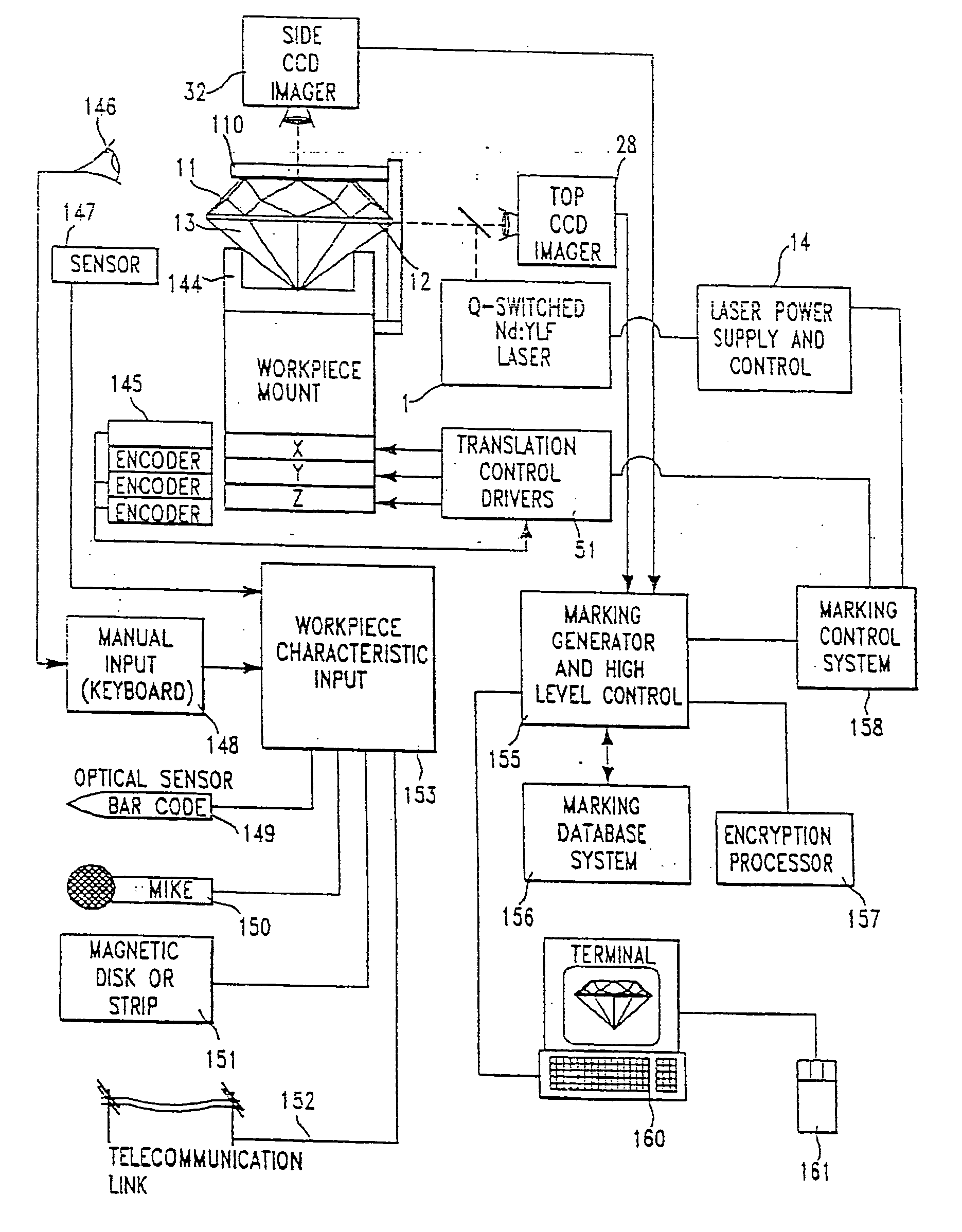

[0090] The detailed preferred embodiments of the invention will now be described with respect to the drawings. Like features of the drawings are indicated with the same reference numerals.

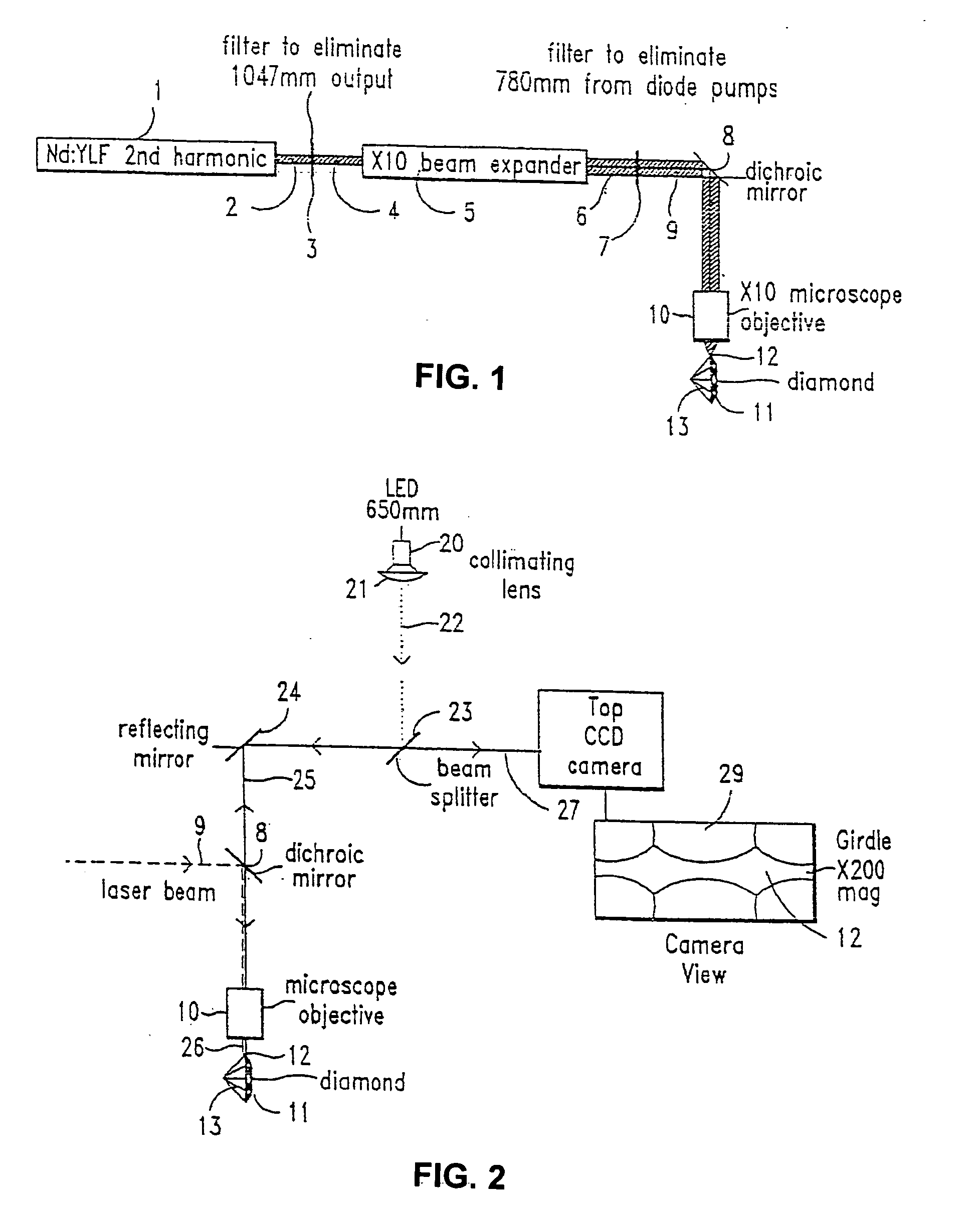

[0091] The system according to the present invention may be used to macro-inscribe alphanumeric characters on the girdle of diamonds 3. It is based on a pulse laser 1, and preferably a Q-switched laser diode pumped solid state laser, to provide minimum volume and installation requirements, and optimum compatibility with any office environment.

[0092] A preferred laser based inscribing system according to the present invention thus contains the following primary elements:

In a vibration isolated frame 140 with shock absorbers 141, at the positions of support:

[0093] (1) Laser diode pumped laser 1 and programmable power supply 14, with a Beam Expander 5.

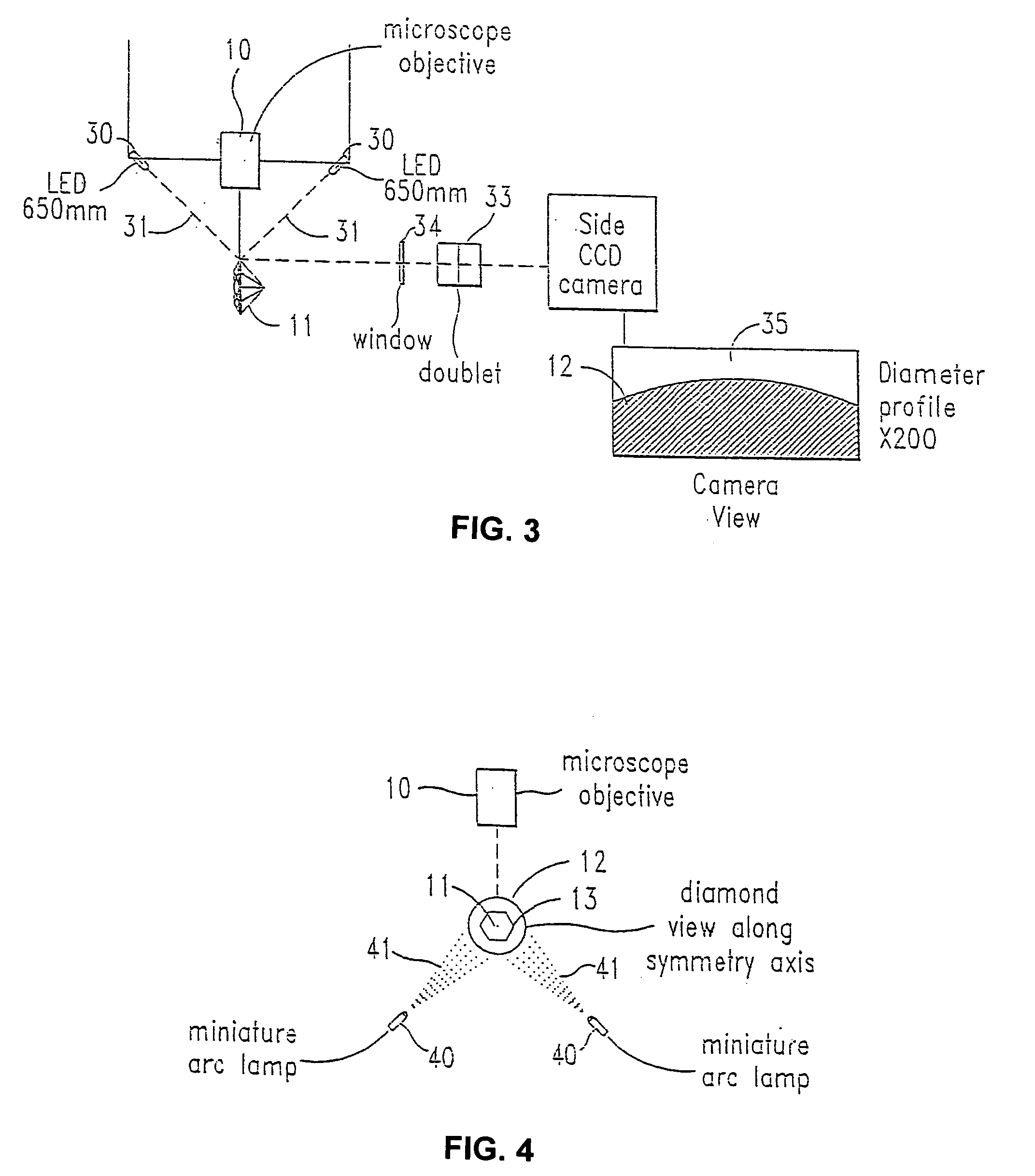

[0094] (2) Optical assembly containing guiding 8 and focusing optics 10, miniature CCD cameras 28, 32 and illumination system.

[0095] (3) XYZ moti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com