A floatable wave energy converter and a method for improving the efficiency of a floatable wave energy converter

A wave energy and converter technology, applied in ocean energy power generation, machines/engines, mechanical equipment, etc., can solve problems such as low efficiency and instability, and achieve the effect of high efficiency and increased energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

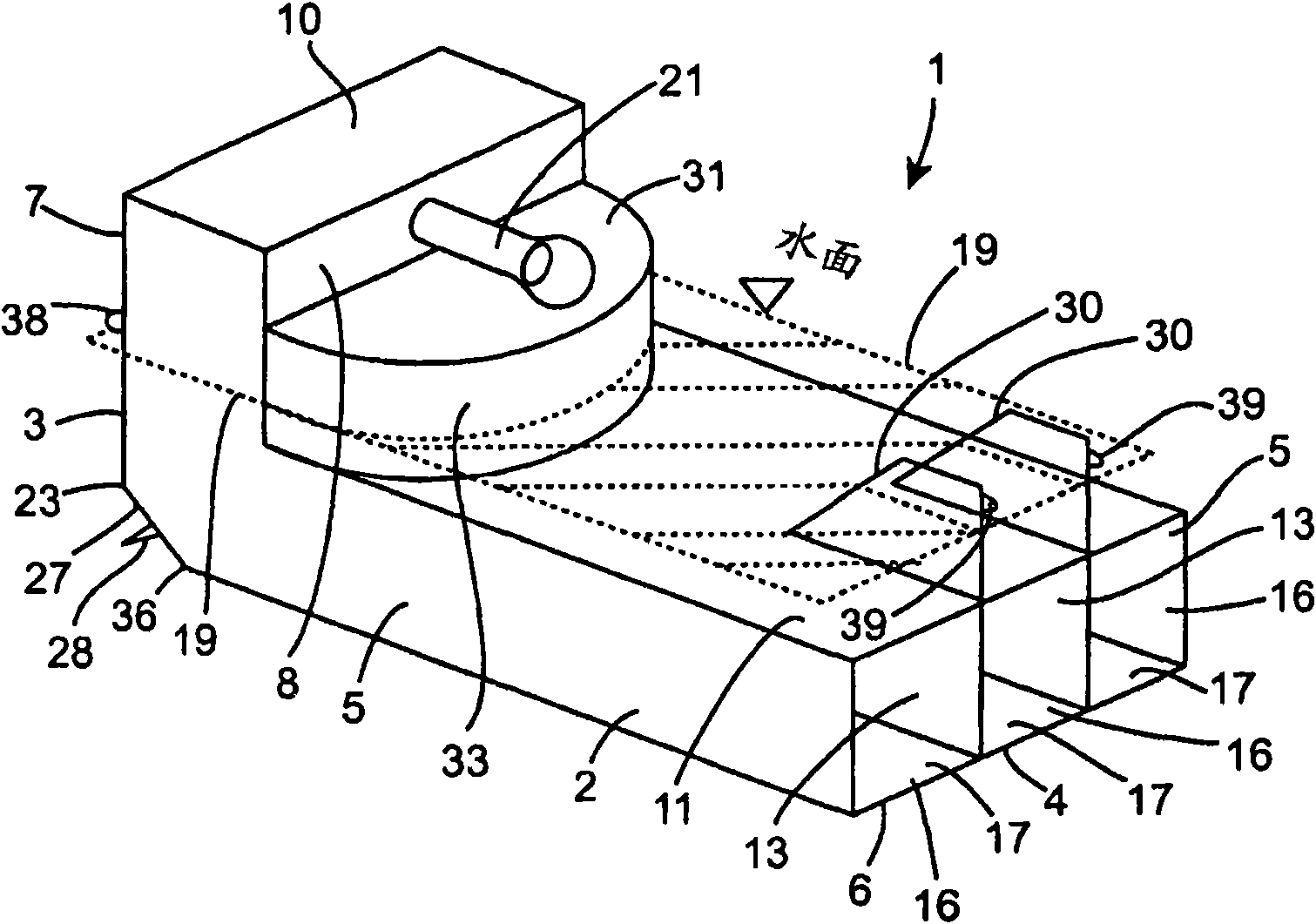

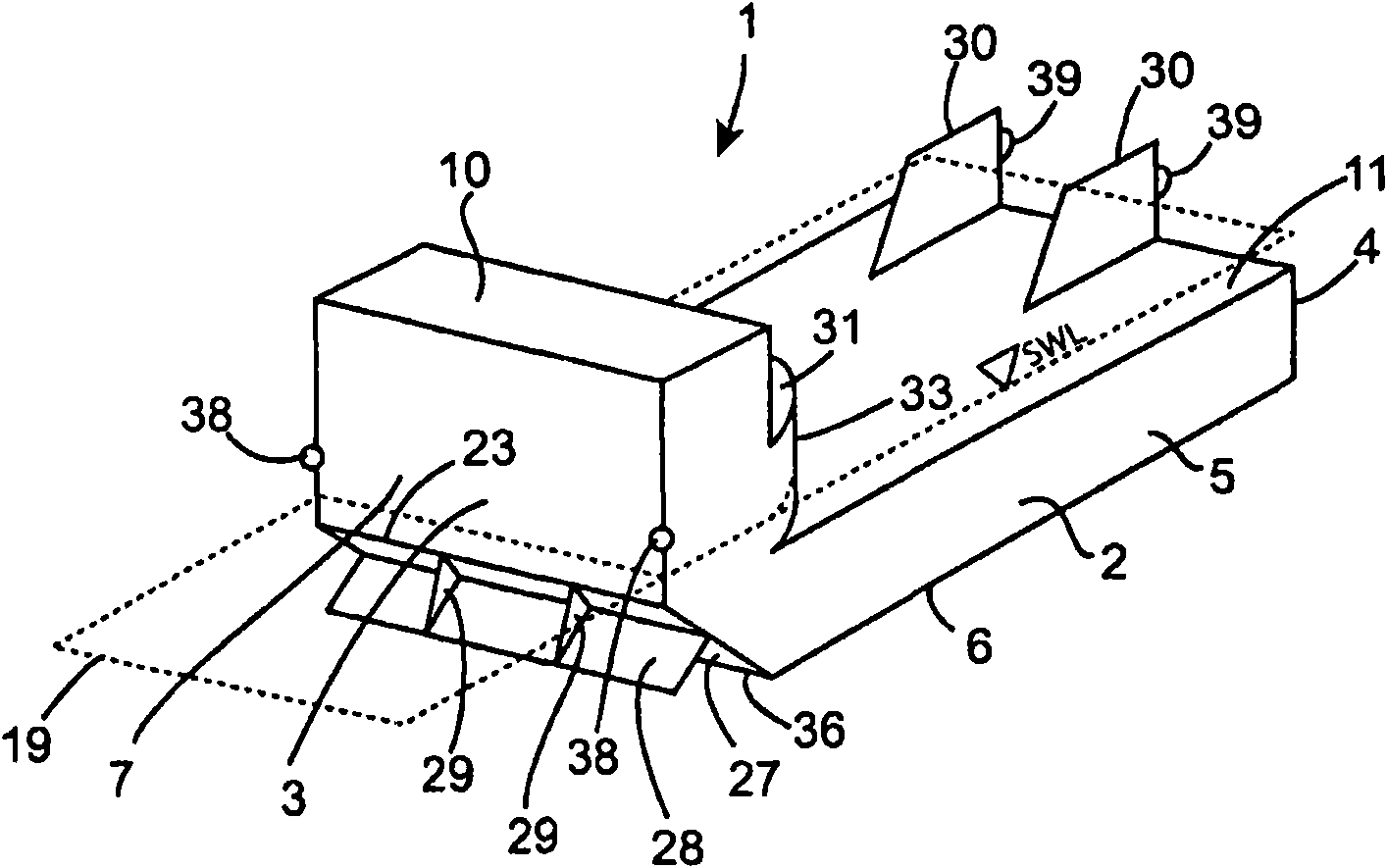

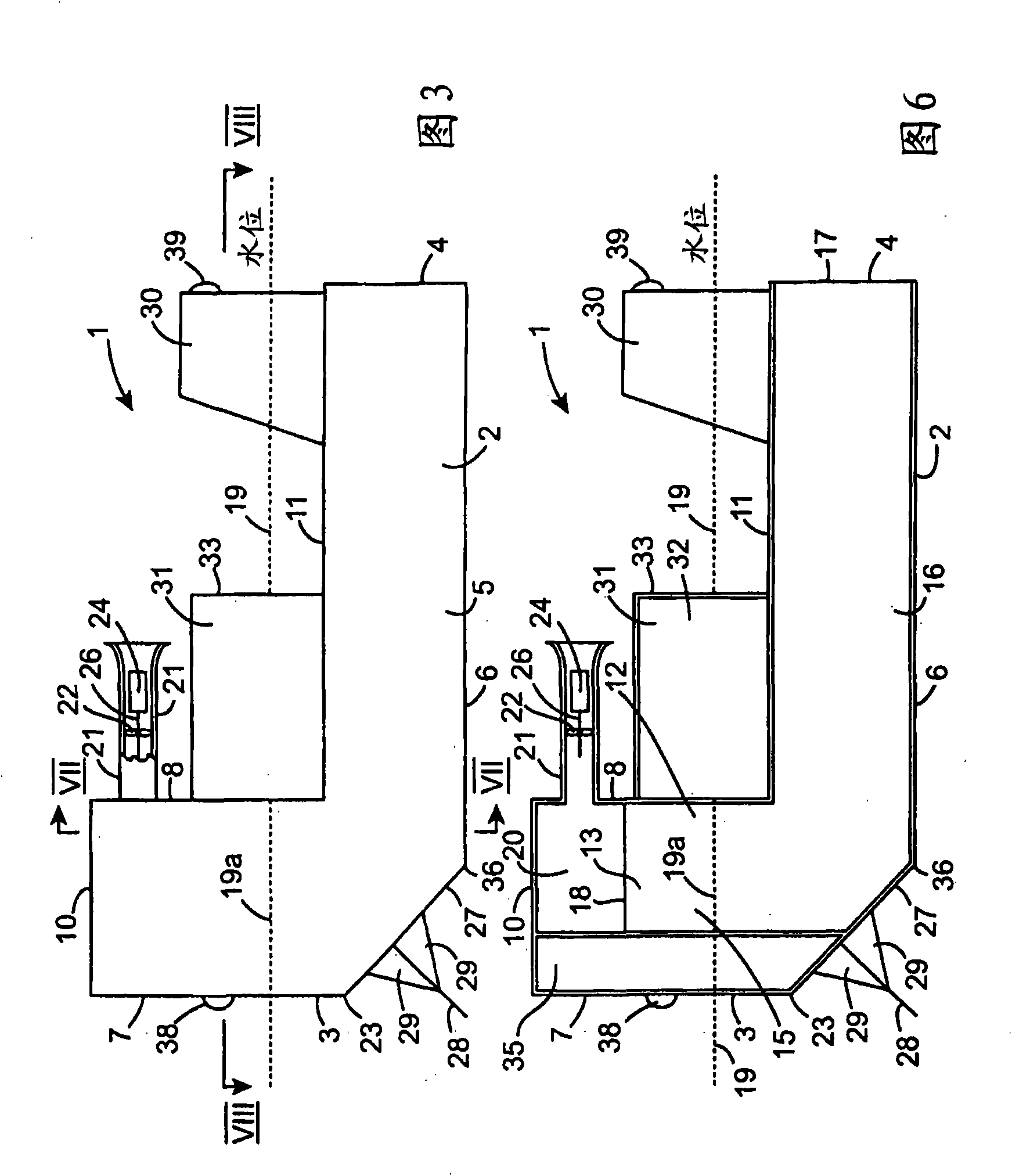

[0059] Referring to the accompanying drawings, there is shown a buoyant wave energy converter according to the present invention, denoted by reference numeral 1, for converting wave energy into mechanical rotational energy and then into electricity. The wave energy converter 1 comprises a shell 2 consisting of a structural steel frame (not shown) covered with panelling. The panels may be of any suitable material, for example sheet or plate metal, concrete or a plastic material such as fiberglass or the like. Of course, the entire shell can be constructed of reinforced concrete. The construction of such housings with structural steel frames and cover panels or other such materials is well known to those skilled in the art. The hull 2 is buoyant on the ocean and extends between the front end 3 and the rear end 4, and is anchored in use with the front end 3 facing the waves so that when waves travel along the hull 2 from the front end 3 to the rear end 4 When passing, it os...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com