Filter system for an electronic equipment enclosure

a filter system and electronic equipment technology, applied in the field of filter systems, can solve the problems of destroying electronic equipment that has not been destroyed, degrading performance, and harsh indoor environment, and achieve the effects of less expensive, less expensive, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] While the present invention is open to various modifications and alternative constructions, the preferred embodiment shown in the various figures of the drawing will be described herein in detail. It is understood, however, that there is no intention to limit the invention to the particular embodiment, form or example disclosed. On the contrary, the intention is to cover all modifications, equivalent structures and methods, and alternative constructions falling within the spirit and scope of the invention as expressed in the appended claims, pursuant to Title 35 U.S.C. section 112 (second paragraph).

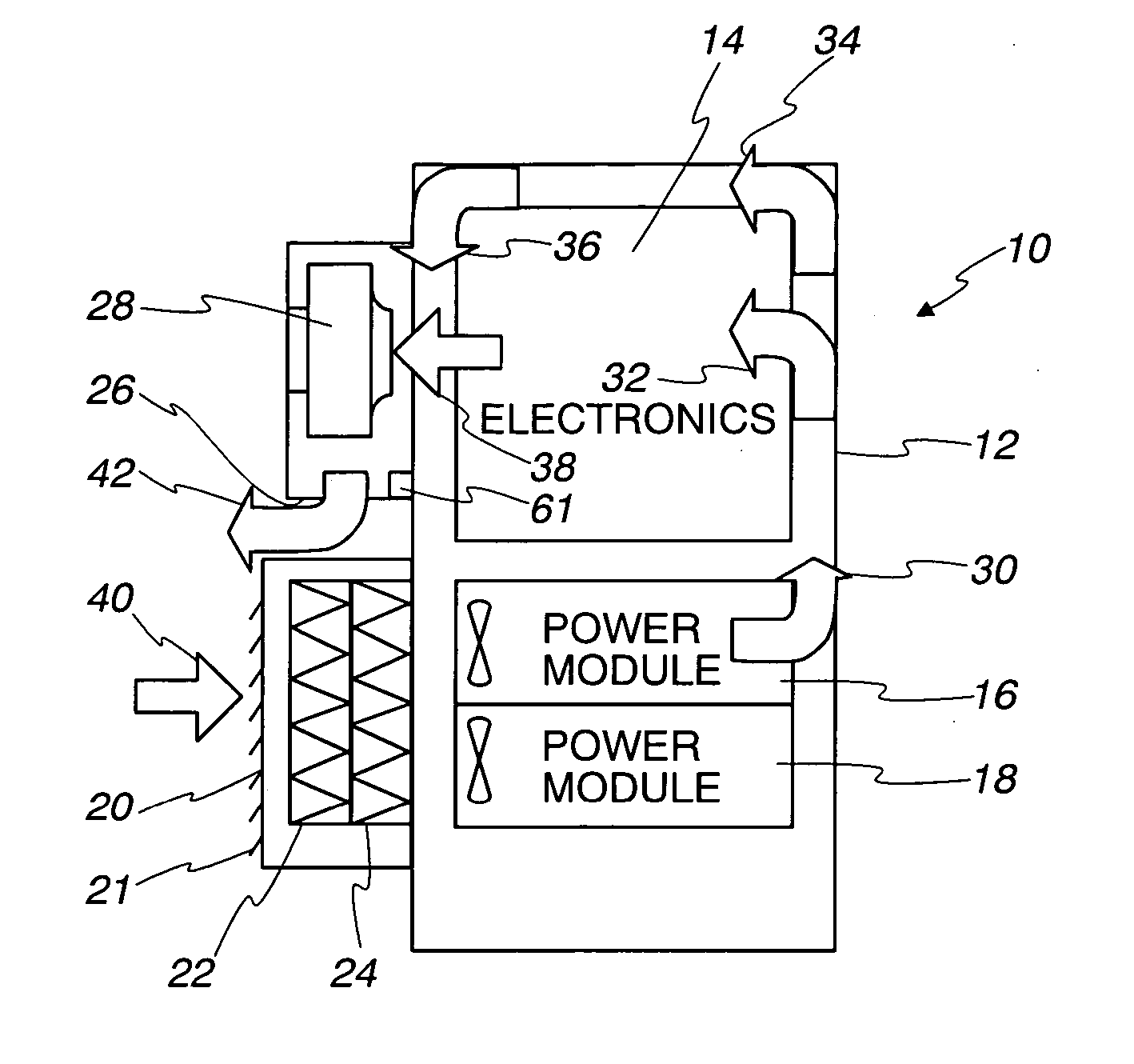

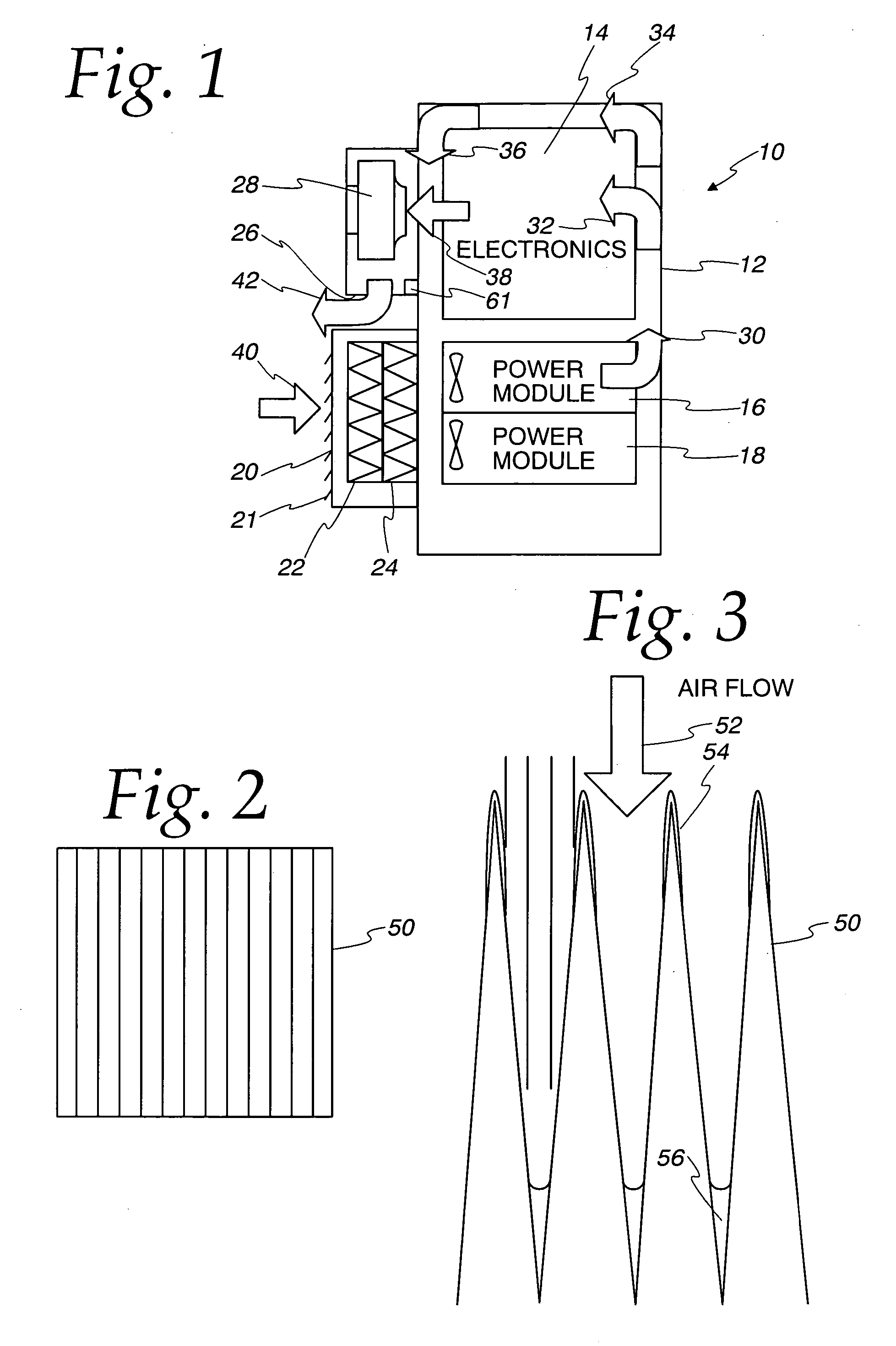

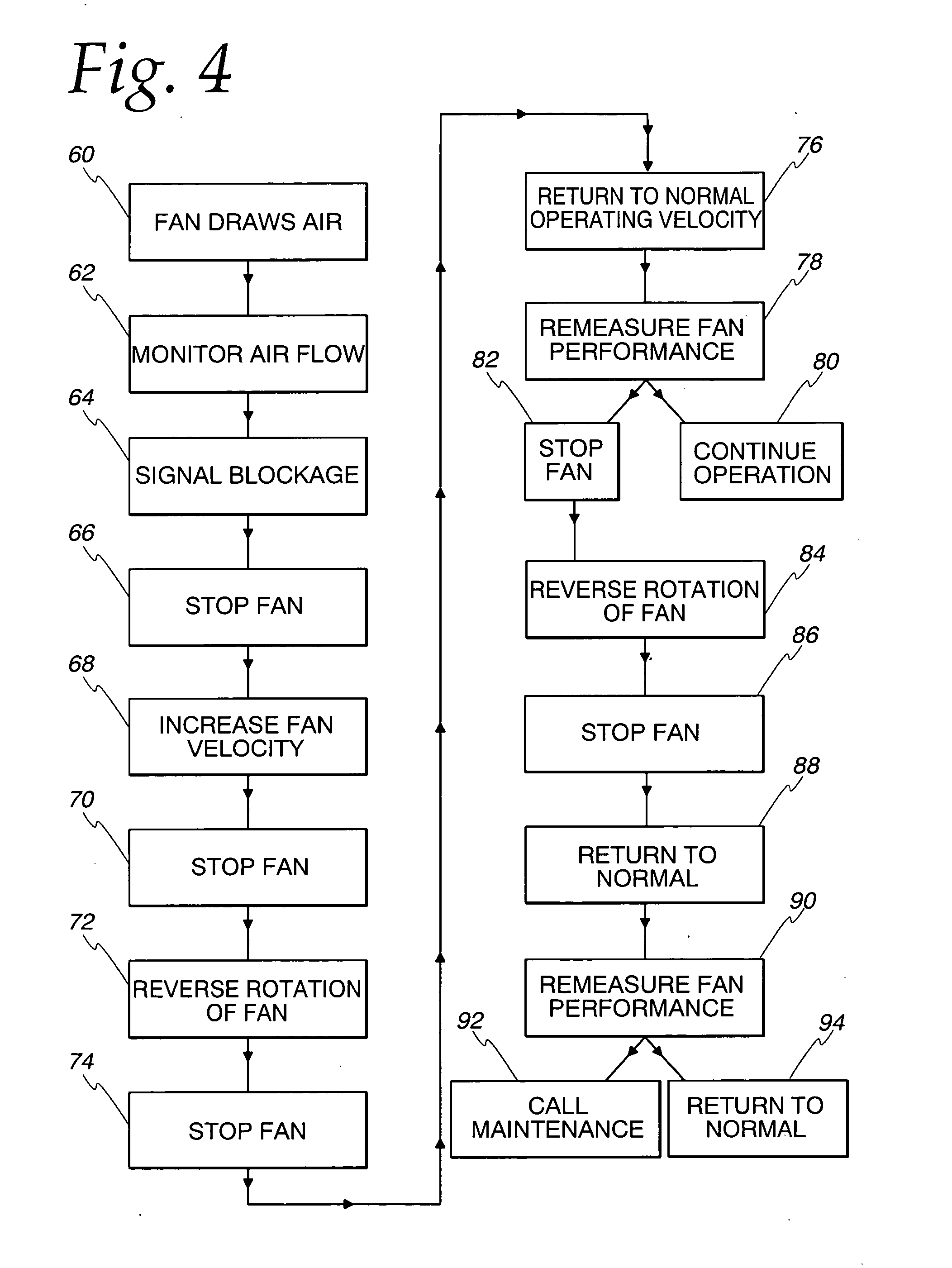

[0021] Referring now to FIG. 1, there is shown a diagrammatical outdoor enclosure 10 having a main housing 12 which has in its upper portion sensitive electronic equipment 14 and in its lower portion two power modules 16, 18. In keeping with the present invention, an inlet housing 20 is provided to allow ingress of ambient air through a louver 21 and two filter elements, an ASHRA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com