Safety valve in pipe

A safety valve and valve plate technology, which is applied in wellbore/well valve device, wellbore/well components, sealing/packing, etc. Problems such as incomplete wax removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

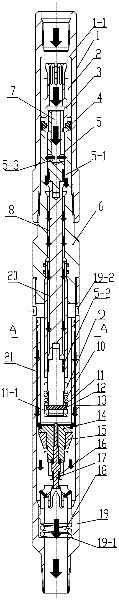

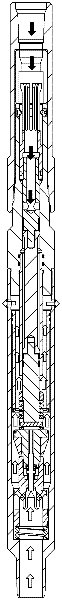

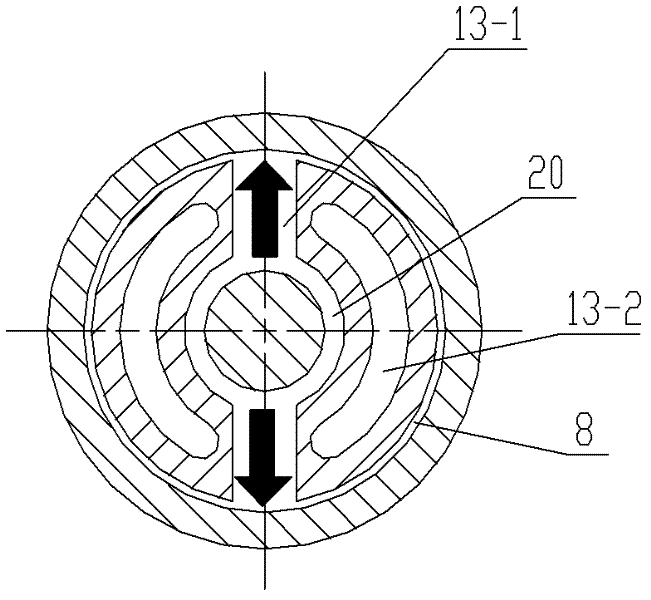

[0033] The new wax-removing and anti-wax oil production process requires that the small-diameter tubing be lowered inside the large-diameter tubing, the large-diameter tubing is sheathed outside the small-diameter tubing, and an oil production channel is formed between the two sets of tubing. The lower end of the small-diameter oil pipe is connected with the in-pipe safety valve provided by the present invention, and the lower end of the in-pipe safety valve is installed with an isolation system. During oil production, high-temperature liquid is circulated in the small-diameter tubing, and the heat is transferred to the production liquid through heat conduction, so that the temperature of the production liquid is higher than the wax formation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com