Screw drilling tool stator prepared from blend of PTFE and FEP, and fluorine-containing material applied to stator

A technology of screw drilling tools and PTFE, which is applied in the field of screw drilling tool stators and fluorine-containing materials, can solve the problems that affect the drilling efficiency and development progress, the technical difficulty of tubular shell processing, and the complicated molding process, etc., and achieve low friction coefficient , good wear resistance, low friction coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The components of this embodiment (in parts by weight) consist of: 100 parts of PTFE and FEP blend, PTFE accounts for 90%, and FEP accounts for 10%; 10 parts of additives, with a diameter of 15 μm and an aspect ratio of 150: 1 carbon fiber and copper powder with a particle size of less than 0.3 μm are mixed at a weight ratio of 2:1. Carbon fibers were treated with a surface modifier prepared by a rare earth modifier with a rare earth concentration of 0.1% and a coupling agent of 2%, soaked at room temperature for 3 hours, and then baked at 80°C for 3 hours.

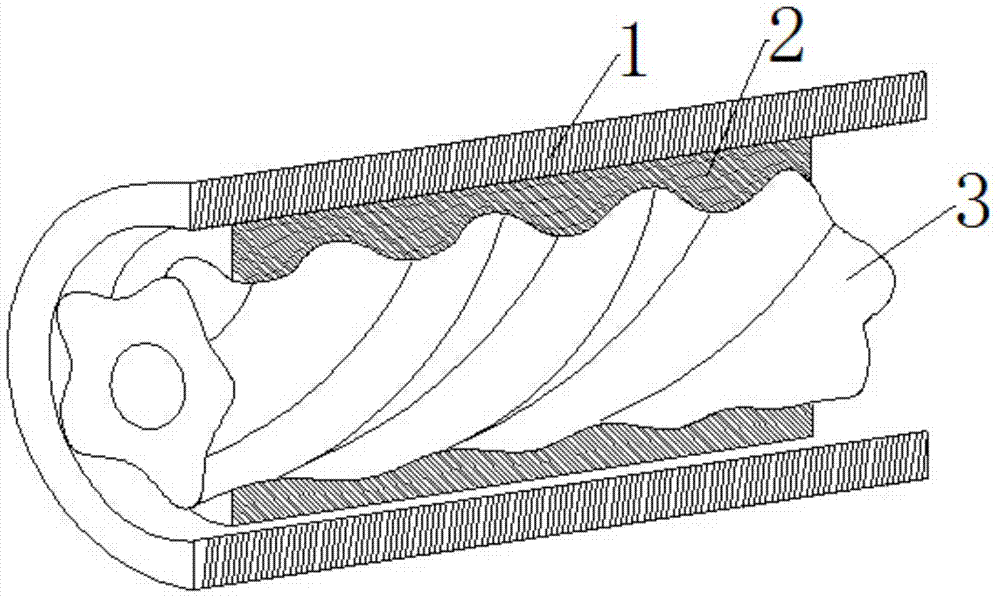

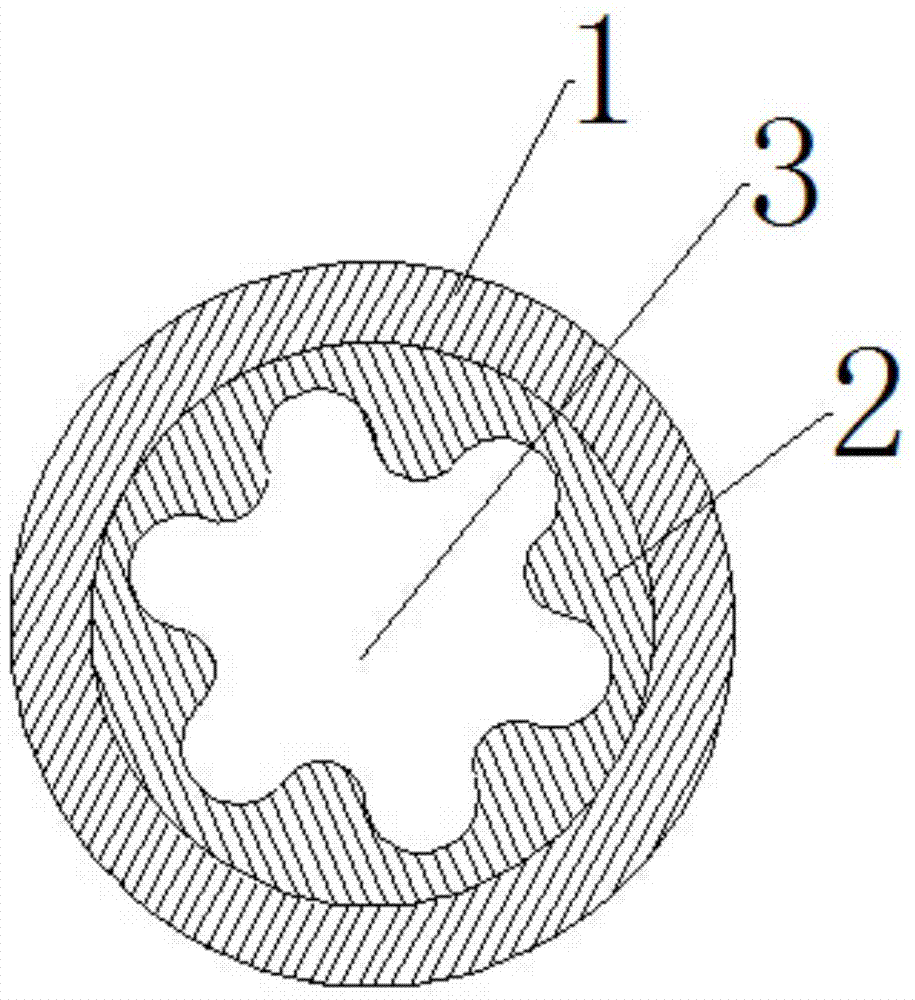

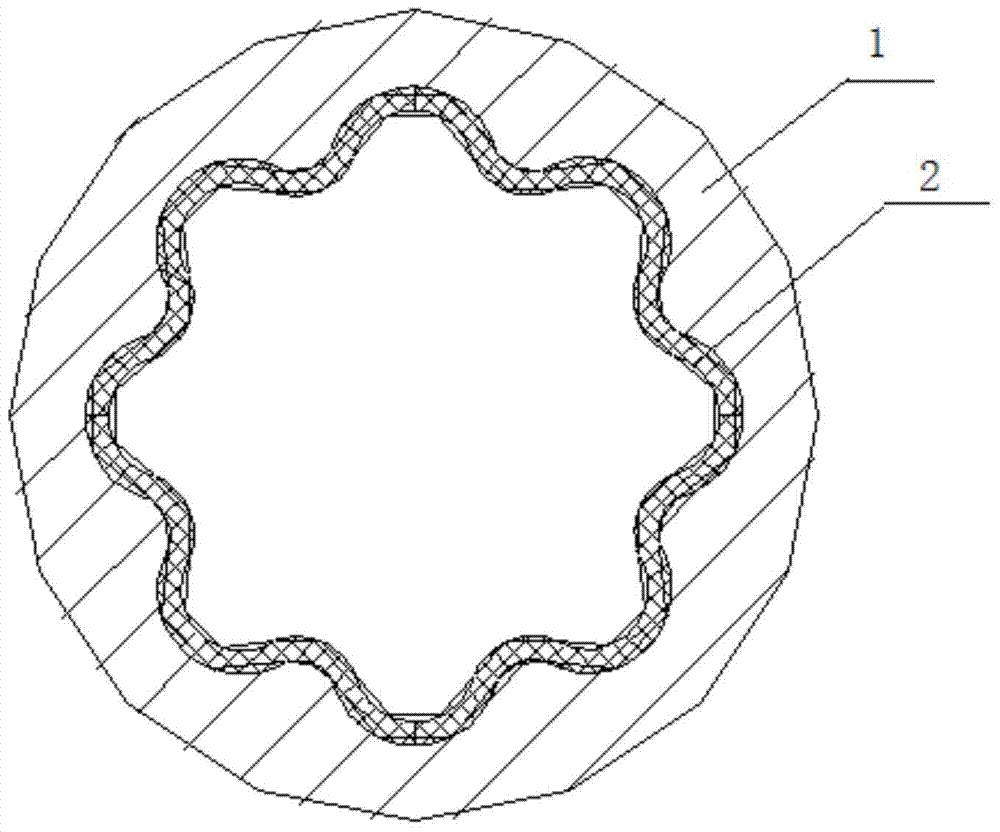

[0053] During production, FEP, PTFE and additives are mixed uniformly by a high-speed kneader, then smelted, extruded and granulated into powder, and then formed by extrusion, injection molding or die casting to obtain one of the application structures such as Figure 1-3 shown.

Embodiment 2

[0055] The components of this embodiment (in parts by weight) consist of: 100 parts of PTFE and FEP blend, PTFE accounts for 80%, and FEP accounts for 20%; 10 parts of additives, with a diameter of 15 μm and an aspect ratio of 150: 1 glass fiber and copper powder and iron powder with a particle size of less than 0.3 μm are mixed at a weight ratio of 2:1. The glass fiber is treated with a surface modifier prepared by a rare earth modifier with a rare earth concentration of 0.2% and a coupling agent of 3%, soaked at room temperature for 2 hours, and then baked at 90°C for 4 hours.

[0056] During production, FEP, PTFE and additives are mixed uniformly by a high-speed kneader, then smelted, extruded and granulated into powder, and then formed by extrusion, injection molding or die casting to obtain one of the application structures such as Figure 1-3 shown.

Embodiment 3

[0058] The components of this embodiment (in parts by weight) consist of: 100 parts of PTFE and FEP blend, PTFE accounts for 75%, and FEP accounts for 25%; 10 parts of additives, with a diameter of 15 μm and an aspect ratio of 150: 1 boron fiber and copper powder and tungsten powder with a particle size of less than 0.3 μm are mixed at a weight ratio of 2:1. The boron fibers were treated with a surface modifier prepared by a rare earth modifier with a rare earth concentration of 0.3% and a coupling agent of 4%, soaked at room temperature for 2 hours, and then baked at 100°C for 4 hours.

[0059] During production, FEP, PTFE and additives are mixed uniformly by a high-speed kneader, then smelted, extruded and granulated into powder, and then formed by extrusion, injection molding or die casting to obtain one of the application structures such as Figure 1-3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com