Crude-oil pipeline wax deposit pigging simulation experiment method

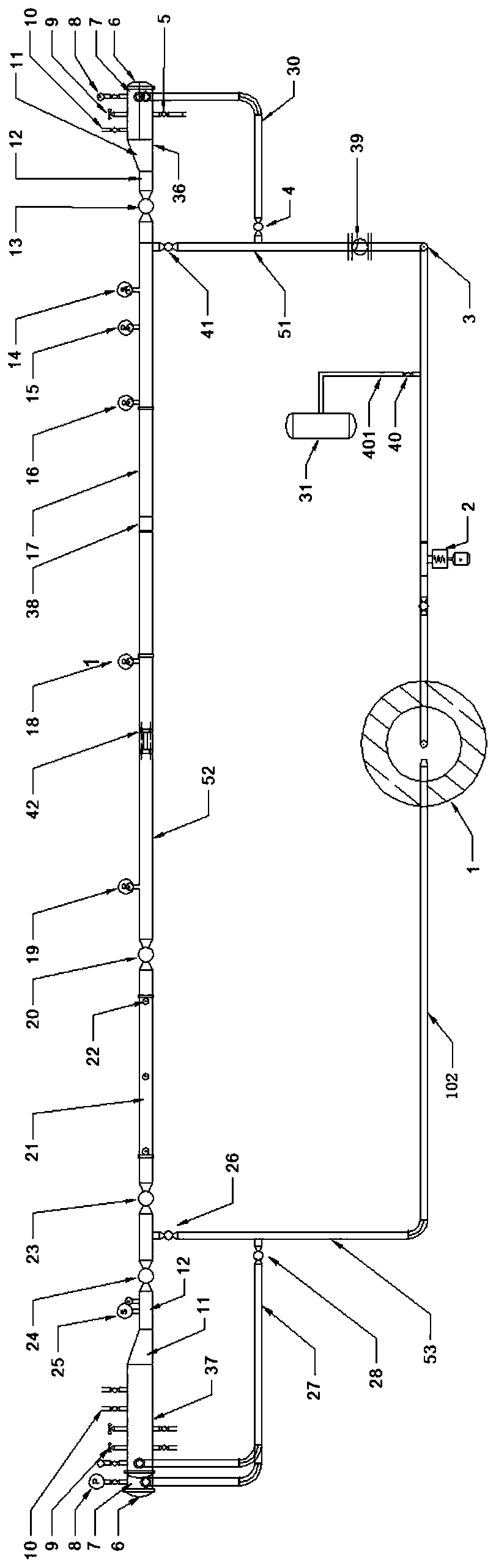

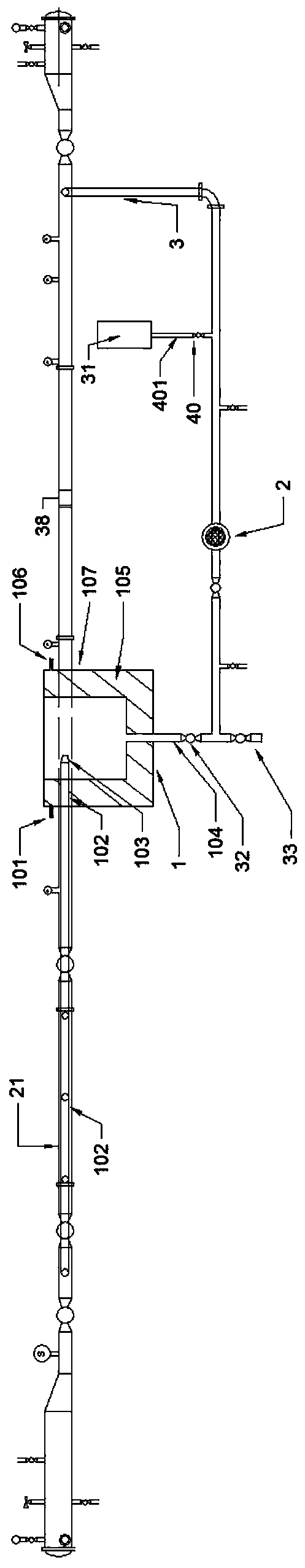

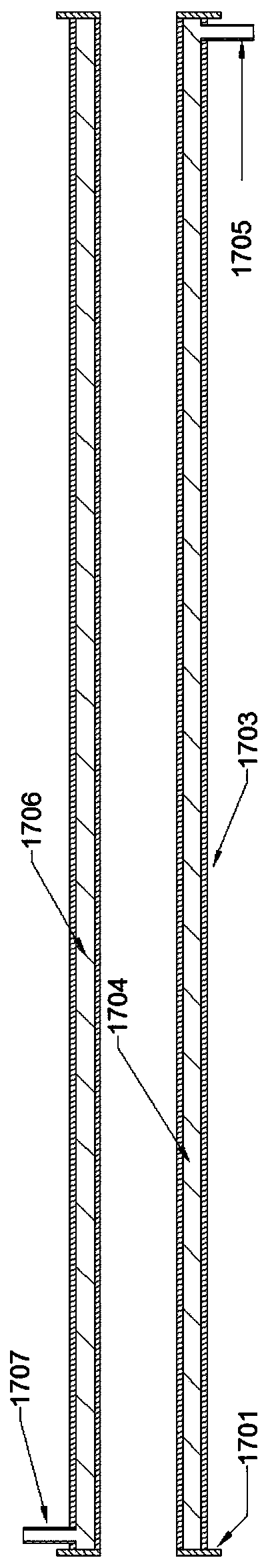

A technology for simulating experiments and wax deposition, applied in cleaning methods and utensils, chemical instruments and methods, material inspection products, etc., can solve problems such as pipeline shutdown accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0104] Under the experimental conditions shown in Table 1, wax deposition experiments were carried out. After reaching the set time of the wax deposition experiment, switch to the pigging process. Under the experimental conditions shown in Table 2, the pigging operation was carried out. For the jet pig 42, under the experimental conditions shown in Table 3, the settling of real wax deposit particles in the oil wax slurry under dynamic conditions and static conditions was observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com