Sliding-rolling combined type soft friction test apparatus

A test device and composite technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as ineffective online simulation, and achieve the effect of ensuring safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

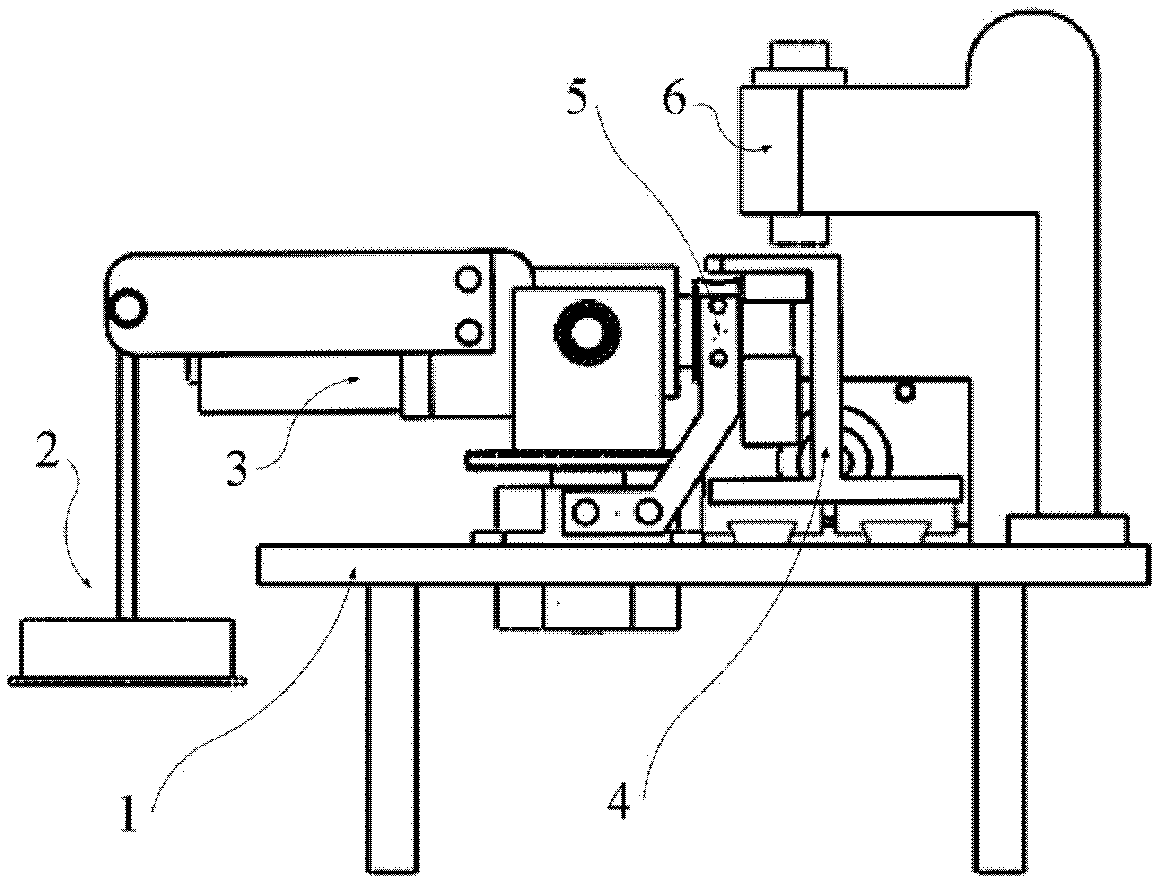

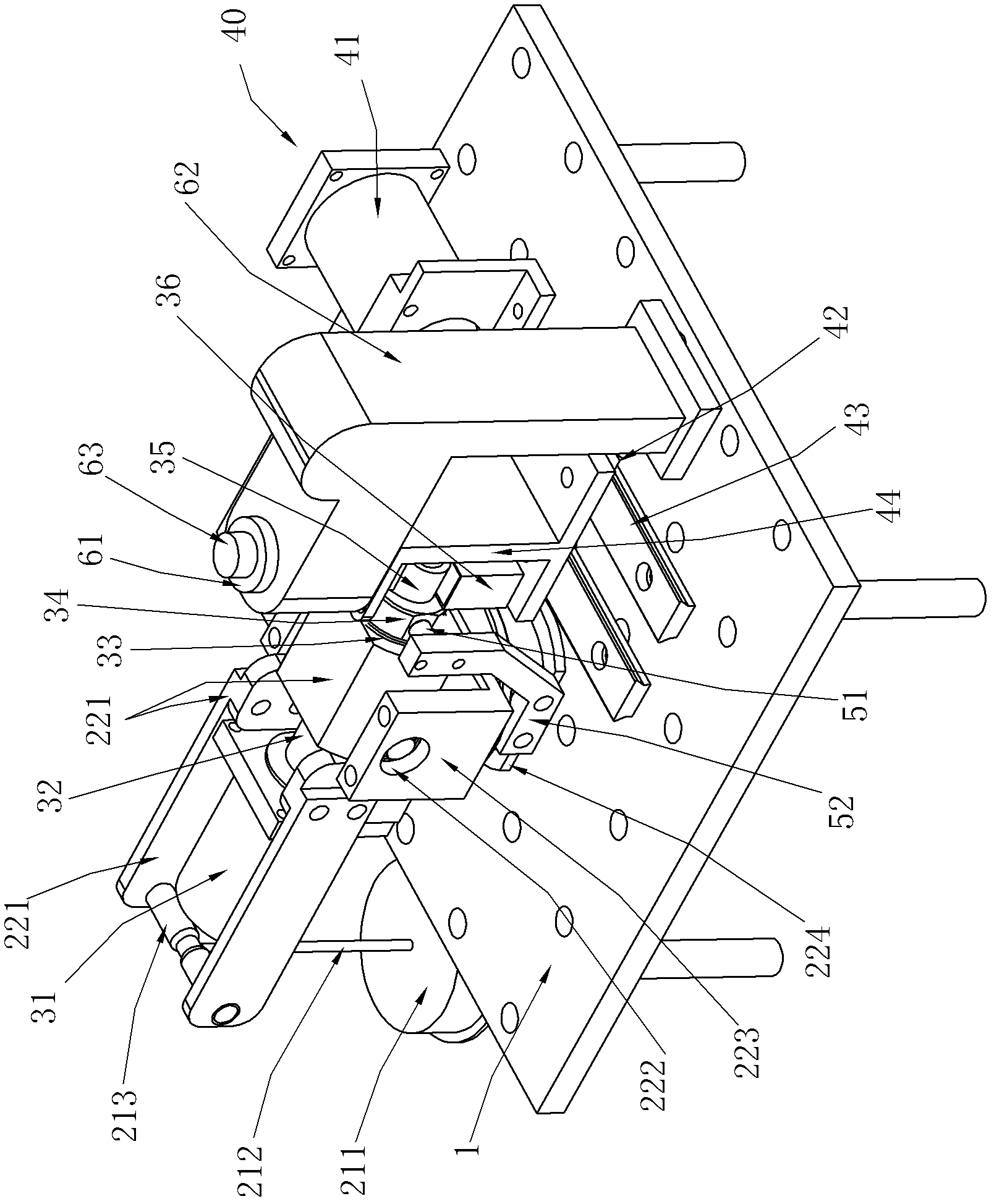

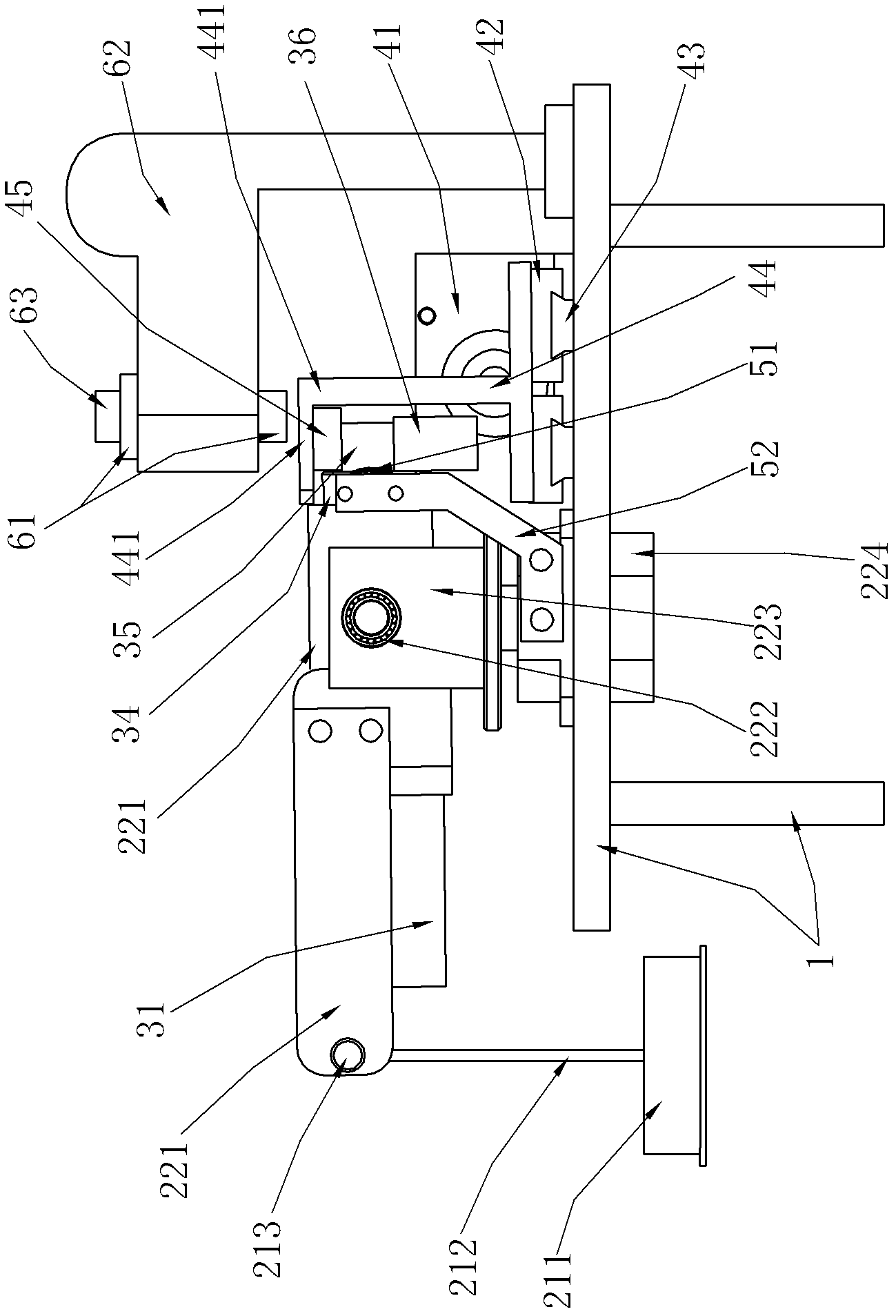

[0038]The sliding-rolling composite soft friction test device proposed by the present invention comprises: a stand; a loading mechanism, which is rotatably supported on the stand; an upper sample mounting frame, which is arranged on the stand, And connected with the driving mechanism, driven by the driving mechanism, it can move linearly in the plane, the upper sample is fixed on the upper sample mounting frame; the lower sample is arranged on the lower part of the upper sample , is rotatably connected with the loading mechanism, and resists the upper sample through the loading mechanism; the friction detection mechanism is arranged on the platform and connected with the loading mechanism; the The hardness of the upper sample and the lower sample is different, and the lower sample is an elastic sample, and the hardness of the upper sample is greater than that of the lower sample; the lower sample is abutted by the loading mechanism On the upper sample, when working, the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com