Multiphase flow pipeline mechanical wax removal simulated test device and mould to manufacture wax deposit

A simulation test and multi-phase flow technology, which is applied in the field of measuring instruments, can solve the problems of not being able to observe the migration and movement of wax removal wax online, and achieve the effects of simple structure, improved safety and reliability, and easy change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

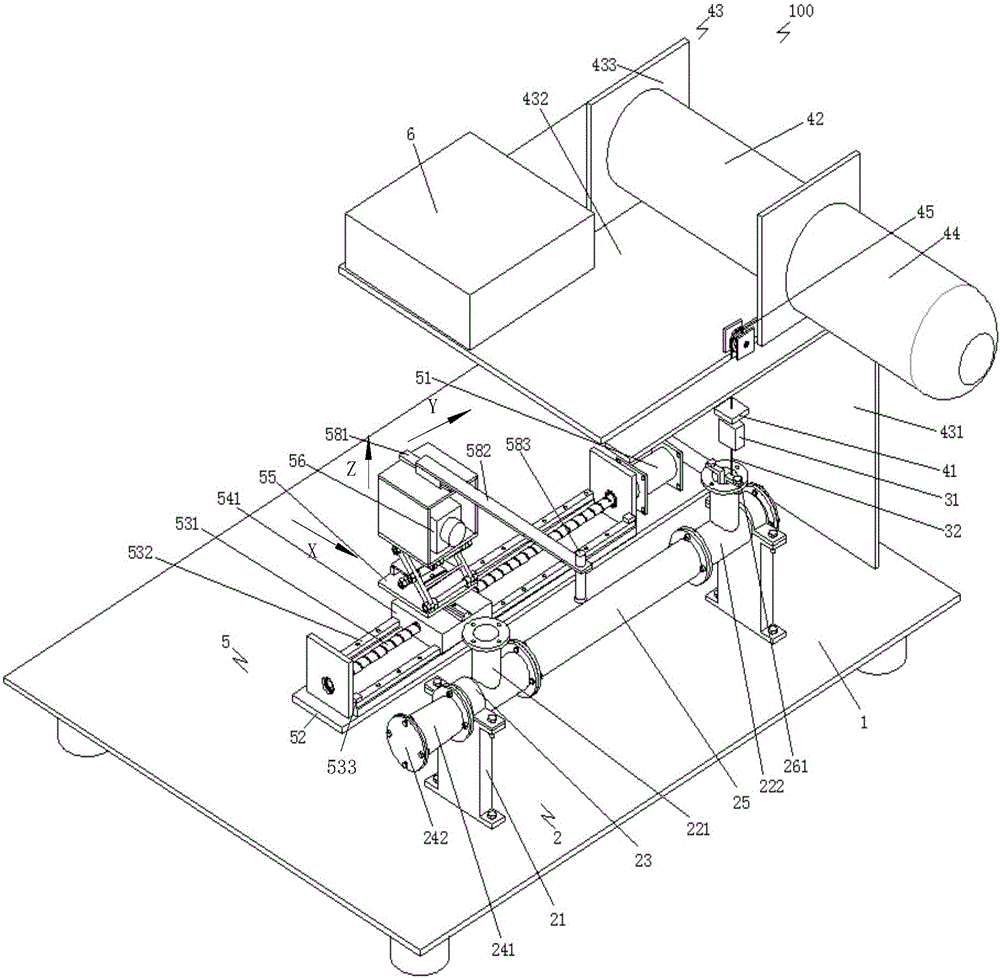

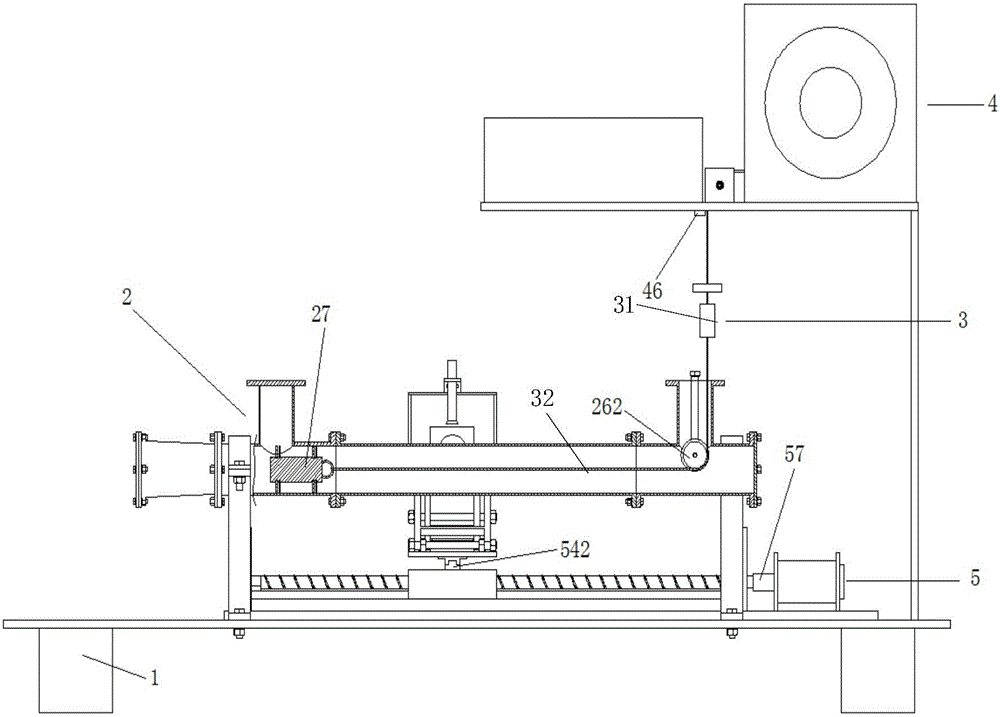

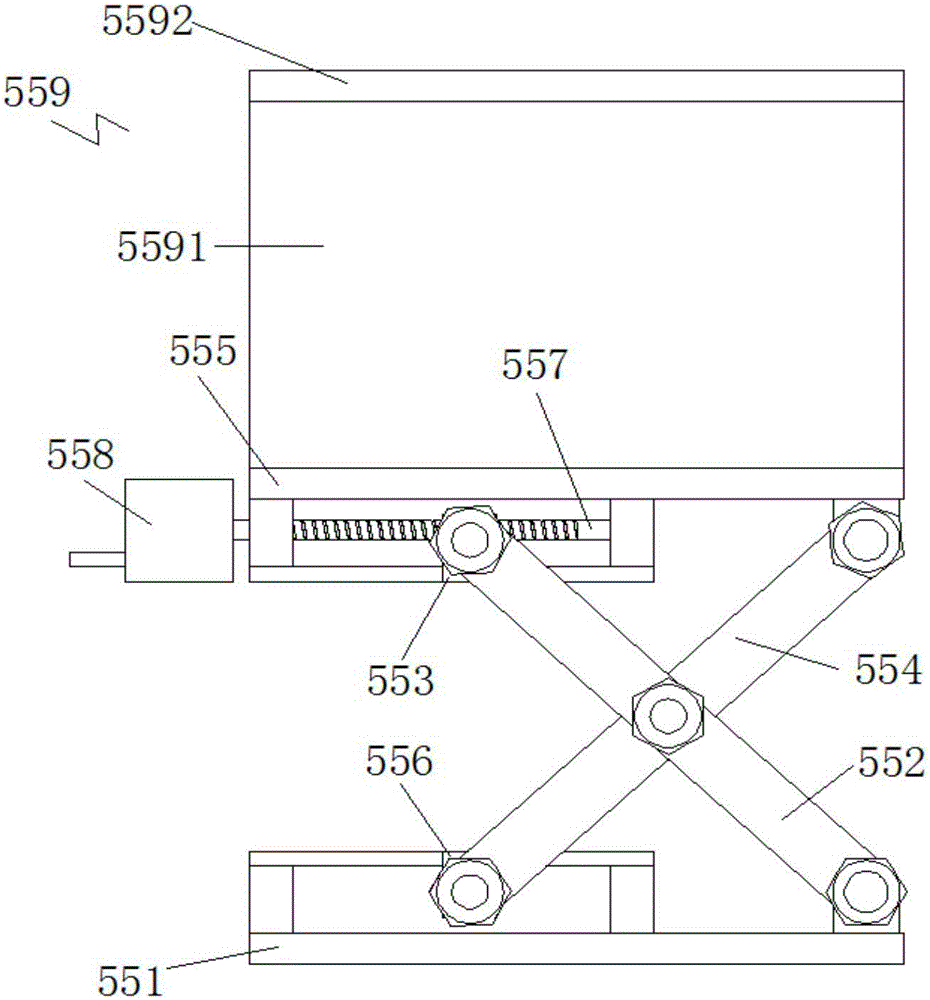

[0064] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

[0065] Such as figure 1 , figure 2 As shown, the multiphase flow pipeline mechanical wax removal simulation test device 100 provided by the present invention includes a test bench 1 arranged at the bottom, and a multiphase flow pipeline assembly 2 is fixedly arranged on the test bench 1, and the multiphase flow pipeline assembly 2 includes a horizontally arranged , and a transparent main pipe 25 with both ends closed, the main pipe 25 is provided with wax deposits arranged axially along the main pipe 25, and the cross section is crescent-shaped, and the main pipe 25 is slidably provided with a pig 27 , the pig 27 is connected with a rope 32 with one end passing through the main pipeline 25. In a specific embodiment, the rope 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com