Delayed coking steam evacuating and cooling system and application thereof

A technology of steam blowing and venting and delayed coking, which is applied in cracking, non-catalytic thermal cracking, petroleum industry, etc., and can solve problems such as temporary solutions but not root causes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

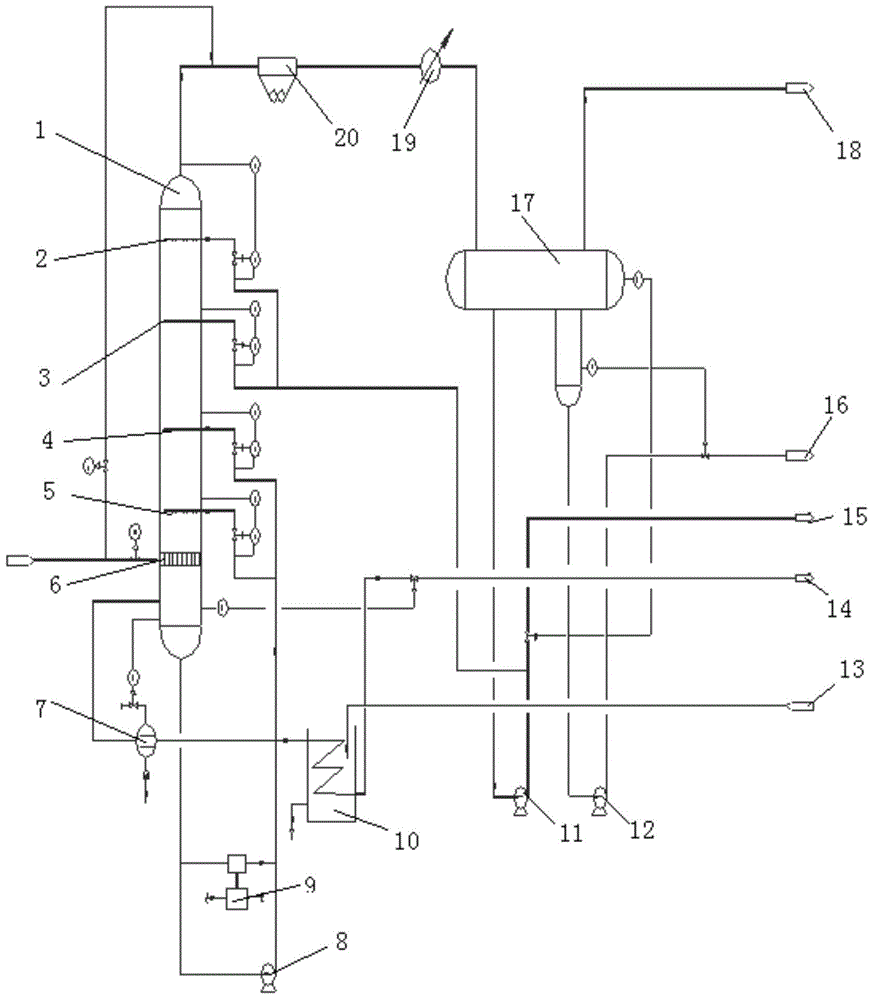

[0013] Such as figure 1 Shown: a delayed coking steam blowing and venting cooling system according to the present invention, including: venting cooling tower 1, tower top reflux distributor A2, tower top reflux distributor B3, tower bottom reflux distributor A4, tower bottom reflux distributor Device B5, gas phase distributor 6, tower bottom reboiler 7, tower bottom sewage pump 8, tower bottom pump 9, tower bottom oil cooling water tank 10, tower top sewage pump 11, sewage pump 12, circulating water system 13, heavy Distillate oil storage tank 14, light distillate oil storage tank 15, sewage treatment system 16, tower top three-phase separator 17, low pressure gas tank 18, tower top air cooler 19, tower top aftercooler 20;

[0014] The inlet of the venting cooling tower 1 at the lower part is connected to the outlet of the coke tower for blowing steam and venting oil and gas. The gas phase distributor 6 is arranged at the inlet of the tower, and the tower bottom reflux distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com