Wax deposition experimental device and method

A technology of experimental device and experimental method, applied in the direction of measurement device, flow characteristics, instrument, etc., can solve the problems of reduced pipeline transportation capacity, wax blocking accident, and increased pigging frequency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

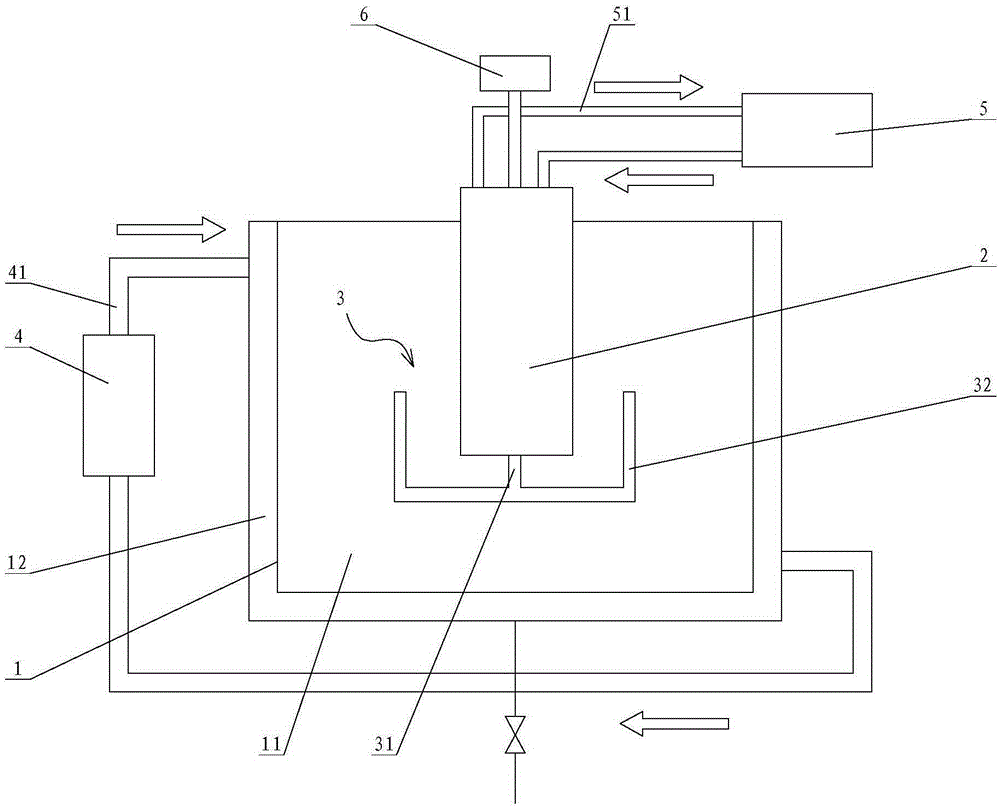

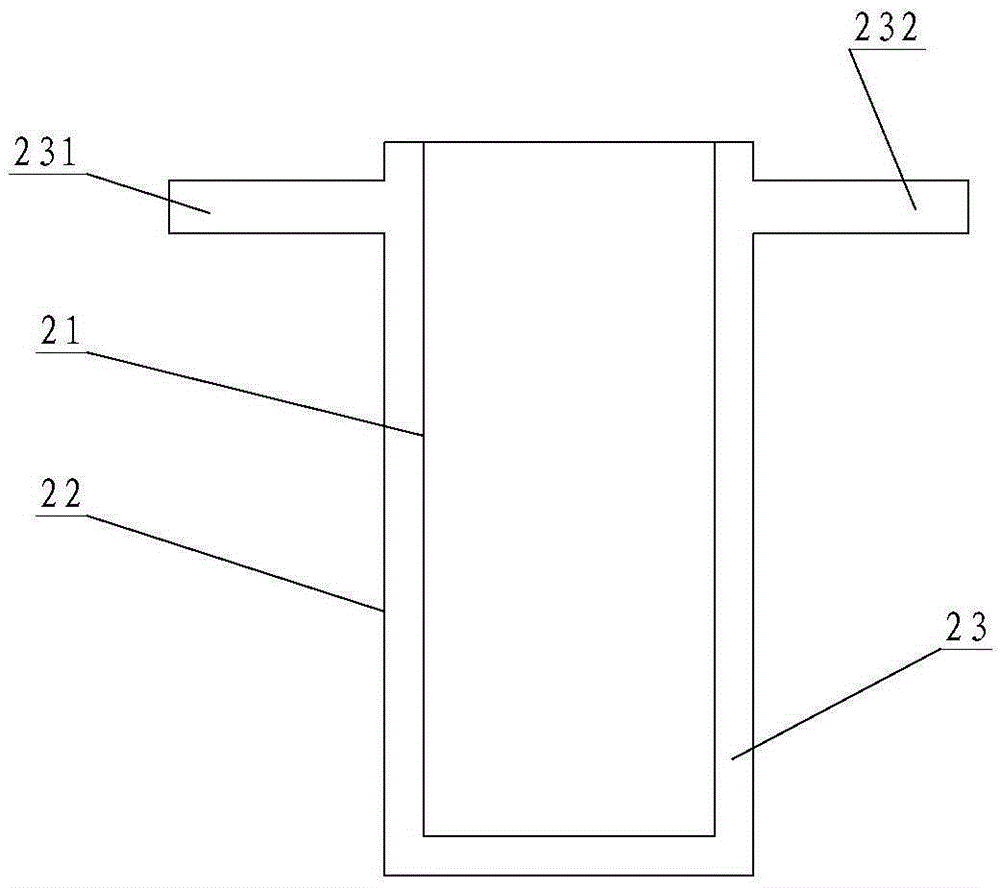

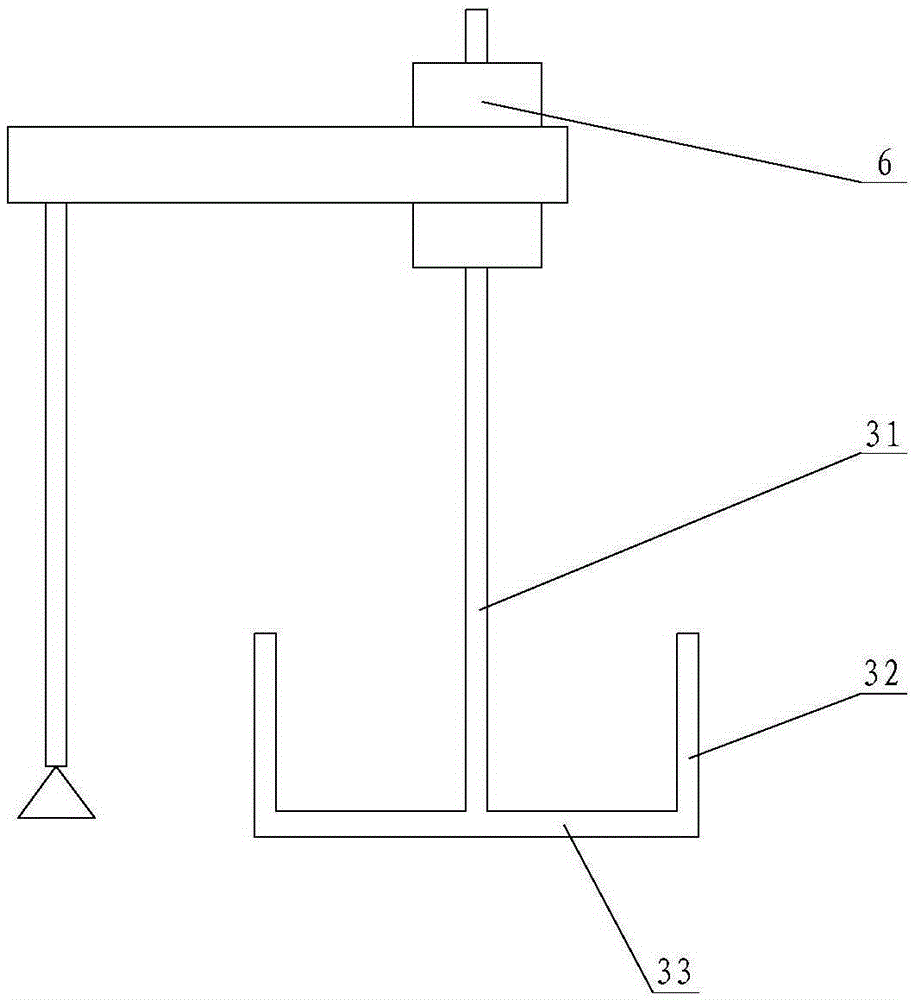

[0028] like figure 1 As shown, the present invention provides a wax deposition experimental device, which includes an oil storage tank 1, a cold finger 2 and an agitator 3, wherein: the oil storage tank 1 has an oil storage chamber 11, and the oil storage tank 1 is covered with a water Jacket interlayer 12, the water jacket interlayer 12 is connected with a first temperature controller 4; the cold finger 2 is arranged in the oil storage chamber 11, and the cold finger 2 has an inner cylinder 21 and is sleeved on the inner cylinder 21 outside the outer cylinder 22, an annular cavity 23 is formed between the inner cylinder 21 and the outer cylinder 22, and the annular cavity 23 is connected with a second temperature controller 5; the agitator 3 has a The rotating shaft 31 in the inner cylinder 21, the end of the rotating shaft 31 passing through the inner cylinder 21 is connected with a plurality of stirring paddles 32, and the stirring paddles 32 are located between the outer p...

Embodiment approach 2

[0071] like Figure 1~3 As shown, the present invention also provides an experimental method using the wax deposition experimental device described in Embodiment 1, the structure, working principle and beneficial effects of the wax deposition experimental device in this embodiment and the wax deposition experimental device in Embodiment 1 Same, no more details here. Described experimental method comprises the steps:

[0072] a) The temperature of the oil in the oil storage tank 1 is controlled at an experimental temperature by the first temperature controller 4;

[0073] b) The temperature of the water in the annular cavity 23 between the inner cylinder 21 and the outer cylinder 22 of the cold finger 2 is controlled to be lower than the oil temperature by the second temperature controller 5, and the water in the annular cavity 23 The temperature is lower than the waxing point temperature of the oil product and higher than the freezing point temperature of the oil product;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com