Pipe cleaning experimental facility suite for crude oil pipeline

An experimental device and pigging technology, which can be applied to measurement devices, instruments, scientific instruments, etc., can solve the problems of reduced pipeline transportation capacity, increased operating energy consumption, and increased flow resistance, and can avoid uneven wall temperature distribution and traction speed. Precise control of stroke and stroke to improve sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

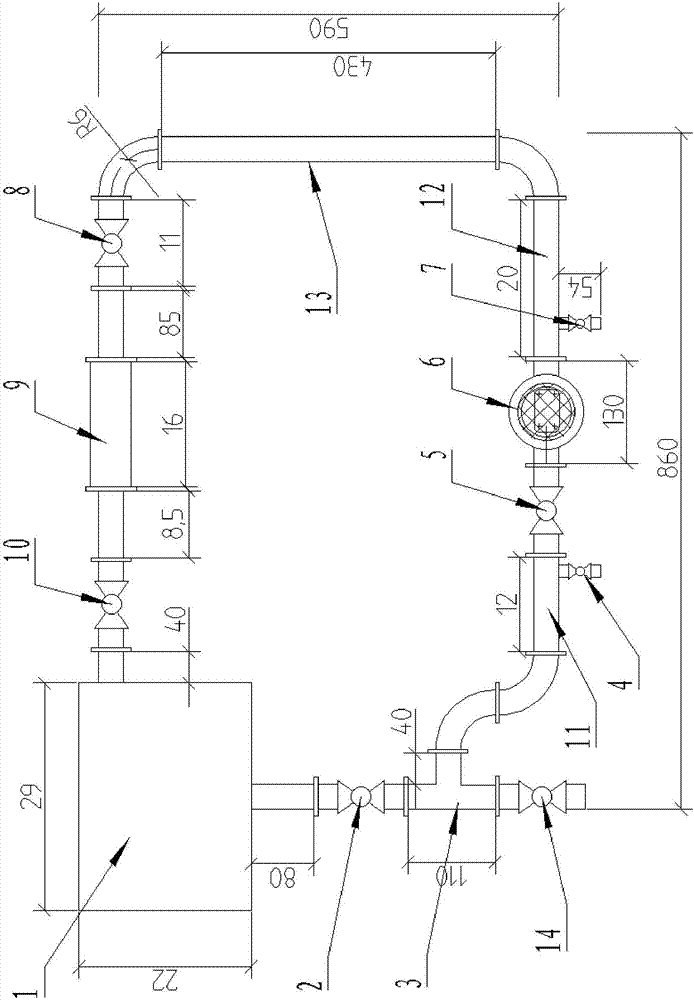

[0054] A crude oil pipeline pigging experimental device kit, including a loop system and a pigging experimental system; the loop system includes an oil tank 1 connected in sequence through pipelines or joints to form a closed circuit, a wax deposition pipe section 9 and a gear oil pump 6, wax deposition The pipe section 9 can simulate the wax deposition process of crude oil during transportation, and the wax deposition pipe section 9 can be unloaded; the pigging experimental system can measure the wax deposit strength and wax removal resistance on the inner wall of the wax deposition pipe section 9, such as figure 1 shown.

[0055] In this loop system, crude oil circulates counterclockwise, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com