Anti-wax anti-scaling anti-corrosion alloy material

An alloy material and anti-corrosion technology, which is applied in the field of anti-wax, anti-scaling and anti-corrosion alloy materials, can solve problems that affect the service life of equipment, environmental pollution, pollution, etc., achieve extended maintenance and replacement cycles, and improve anti-scaling and waxing functions , the effect of reducing production costs

Active Publication Date: 2011-06-15

恩曼自动化技术(上海)有限公司

View PDF2 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The chemical agent treatment method is based on chemical reaction, and the chemical agent itself is a polluting and corrosive substance, and it is easy to chemically react with pipelines and equipment. Therefore, it is easy to cause environmental pollution and corrode equipment, affecting the service life of equipment; Physical methods of processing equipment, pipeline anti-wax, anti-scaling and anti-corrosion often cannot achieve the desired effect, and an external power supply is required, and there must be no magnetic field interference around, otherwise the use effect will be very poor

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

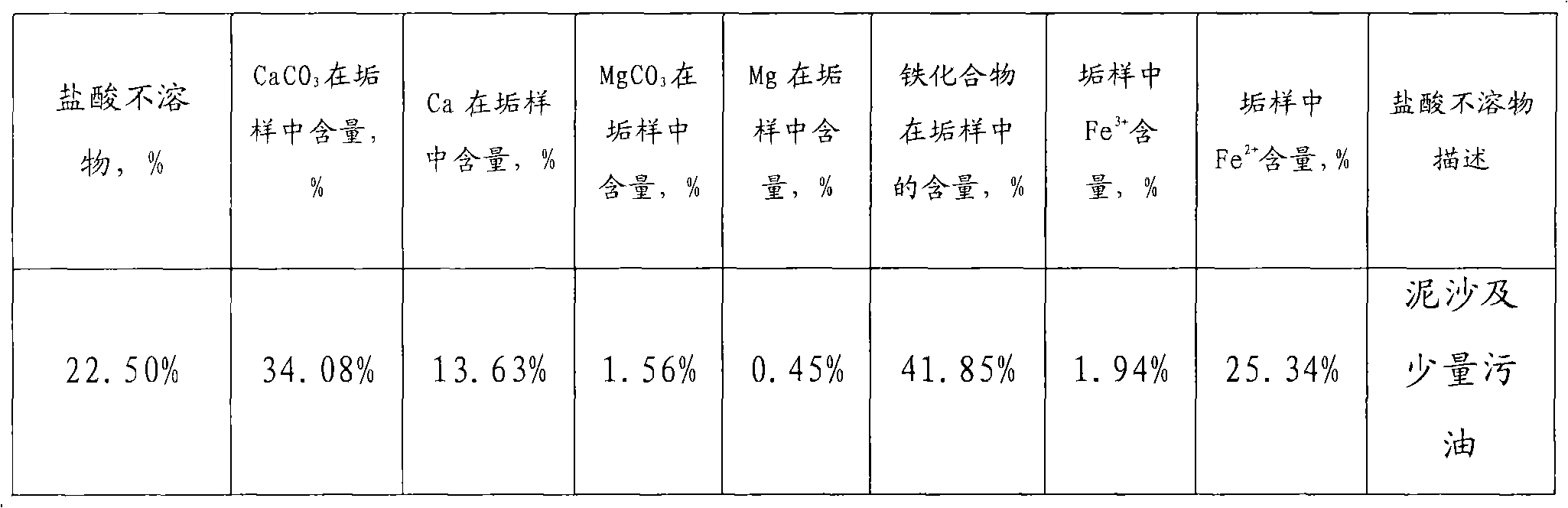

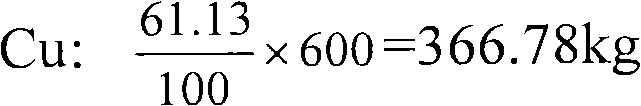

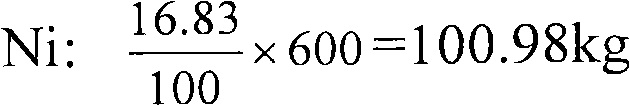

The invention provides an anti-wax anti-scaling anti-corrosion alloy material. The alloy material is used for a protective device of a pipeline or equipment in industrial production, such as an anti-wax anti-scaling anti-corrosion device, and is prepared by smelting the following nine components in percentage by weight: more than 52 percent and less than 65 percent of Cu, more than 14.2 percent and less than 20 percent of Zn, more than 15 percent and less than 19 percent of Ni, more than 2 percent and less than 3 percent of Pb, more than 3 percent and less than 5 percent of Sn, more than 0.23 percent and less than 0.43 percent of Fe, less than 0.005 percent of Sb and the balance of S and Mn. By the anti-wax anti-scaling anti-corrosion device made of the alloy material, the corrosion resistance and scaling prevention and wax deposition prevention functions of metallurgical equipment and oil extraction equipment are greatly improved, the maintenance period and replacement period of industrial equipment are prolonged, and production cost is reduced.

Description

A kind of anti-wax, anti-scaling and anti-corrosion alloy material technical field The invention relates to an anti-wax, anti-scaling, and anti-corrosion alloy material, in particular to an anti-wax, anti-scaling, and anti-corrosion alloy material for pipelines or equipment in industrial production. Background technique In industrial production, such as iron and steel plants, chemical plants, smelters, food plants, and paper mills, pipelines and equipment have serious problems of wax deposition, scaling, and corrosion. Currently, chemical and physical methods are commonly used to deal with such problems. The chemical agent treatment method is based on chemical reaction, and the chemical agent itself is a polluting and corrosive substance, and it is easy to chemically react with pipelines and equipment. Therefore, it is easy to cause environmental pollution and corrode equipment, affecting the service life of equipment; Physical methods to deal with equipment, pipeline anti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C9/06C22C9/04

Inventor 何立新

Owner 恩曼自动化技术(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com