Method for replacing diesel oil with ammonium nitrate emulsified oil as diesel engine fuel

A technology of ammonium nitrate and emulsified oil, which is applied in the direction of fuel, liquid carbon-containing fuel, petroleum industry, etc., can solve the problems of exhaust pollution, no revolutionary change, high power, etc., and achieve reduced operating costs, stable structure, and extended The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

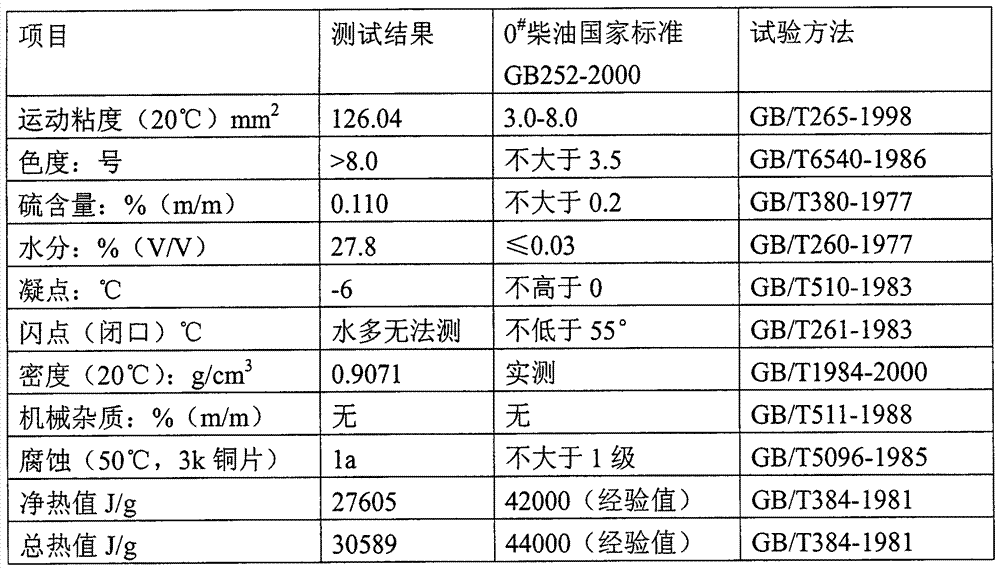

Examples

Embodiment approach

[0017] In order to adapt to the characteristics of low calorific value, high water content, high viscosity and slow temperature rise of emulsified oil, when replacing diesel with emulsified oil, the diesel engine must be adjusted.

[0018] 1. Advance the advance angle of the fuel injector by two teeth (≥15°) on the basis of the original, so that the emulsified oil enters the combustion chamber to preheat in advance.

[0019] 2. Reduce the circulating cooling water in the cooling system by about 20% to reduce the heat taken away by the cooling water. When the emulsified oil is working, the temperature of the water tank should not be lower than 85°C.

[0020] 3. The cross-sectional area of the air inlet of the air filter is reduced by 50%, and the air intake volume is reduced by about 40%, so as to reduce the heat taken away by the exhaust.

[0021] 4. There is a cooling water jacket in the combustion chamber of the water-cooled diesel engine, and the mechanical strength is li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com