Ceramic tile decorated by dry lamination of colorful particles and micro powder and preparation method of ceramic tile

A ceramic tile, dry mixing technology, applied in the field of architectural ceramics, can solve the problems of easy to appear color group, rigid decorative effect, small particle size, etc., to achieve the effect of strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the drawings and the following embodiments. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

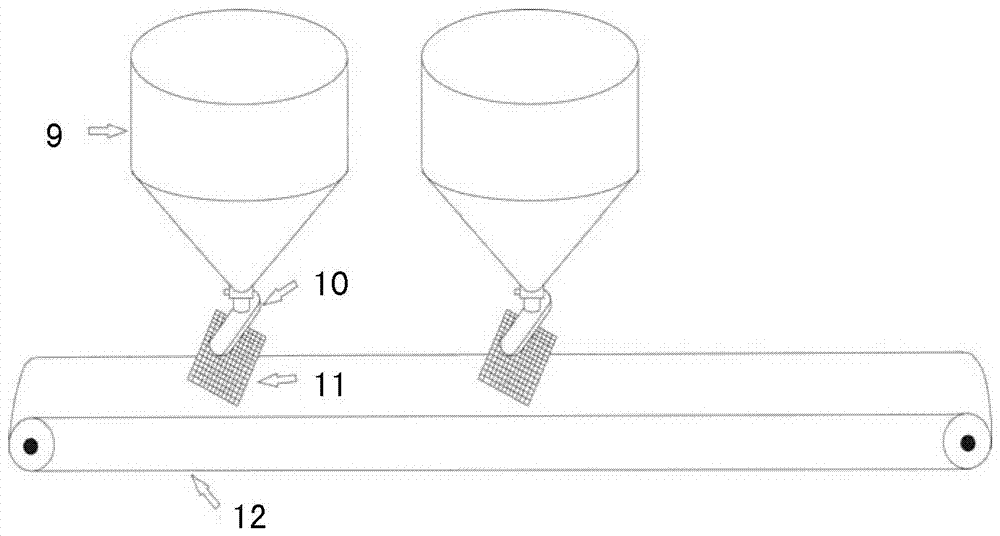

[0069] The main technological process of existing ceramic tiles, such as polished tiles, includes: raw materials - ball milling - sieving and iron removal - color matching - spray drying - storage - batching - granulation - cloth - pressing - drying - glazing - firing - polishing - Grading packaging - warehousing, etc. However, the present invention aims at defects such as simple and stiff patterns and poor decorative effects caused by the roller grid cloth process adopted in the prior art. , The fabric link has been improved. For this reason, the present invention provides a kind of preparation method of the ceramic brick of dry method magic color particle, micropowder composite decoration,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com