Automatic laboratory asphalt filling device

An automatic filling and laboratory technology, applied in the direction of melting and processing tar asphalt/petroleum asphalt/natural asphalt, and preparation of test samples. In order to achieve the effect of reducing manual operation errors and labor costs, meeting control requirements, and efficient control requirements

Pending Publication Date: 2019-01-22

CHANGSHA LUSHENG INSTR EQUIP

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The traditional asphalt sampling filling method adopts manual sampling. First put the asphalt into the heating container, place it on the electric furnace to heat to melt the asphalt, and then pour it into the test container. This process requires a lot of manual operation techniques and experience. High, it is difficult to grasp the accuracy of the filling amount. Once the temperature drops after adding too much to the test container, the sample cannot be poured out. The sample container needs to be cleaned and refilled.

Since the temperature of the asphalt sample in the heating container cannot be controlled by direct heating with an electric furnace, if the temperature is too high, the asphalt will easily age. If the temperature is too low, when the asphalt heating container leaves the heat source, the temperature of the asphalt sample will drop and solidify within a short time

The traditional asphalt sampling method should be poorly controlled, resulting in the data of asphalt performance analysis tests are often not accurate enough, and the operation is very inconvenient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

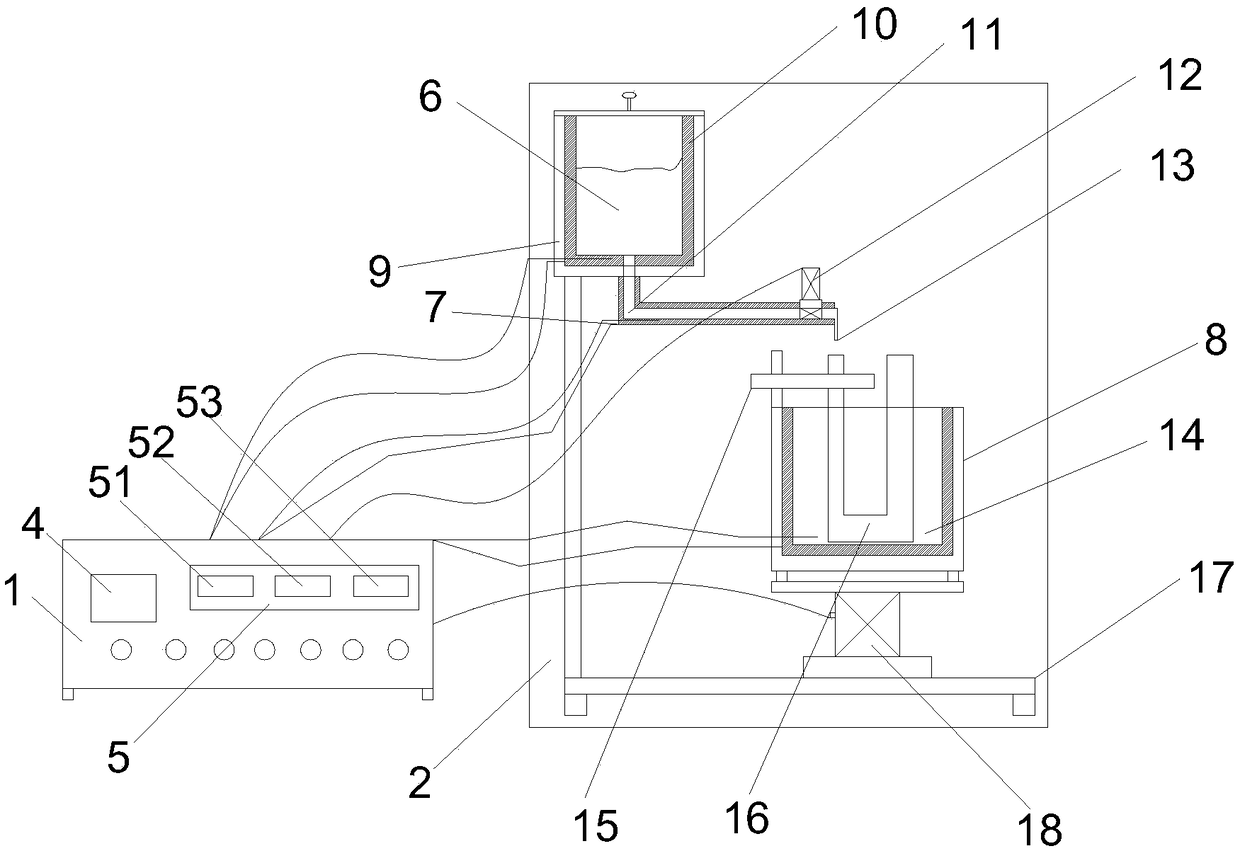

[0027] Such as Figure 1-3 As shown, the structure setting of the laboratory asphalt automatic filling device provided in this embodiment:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

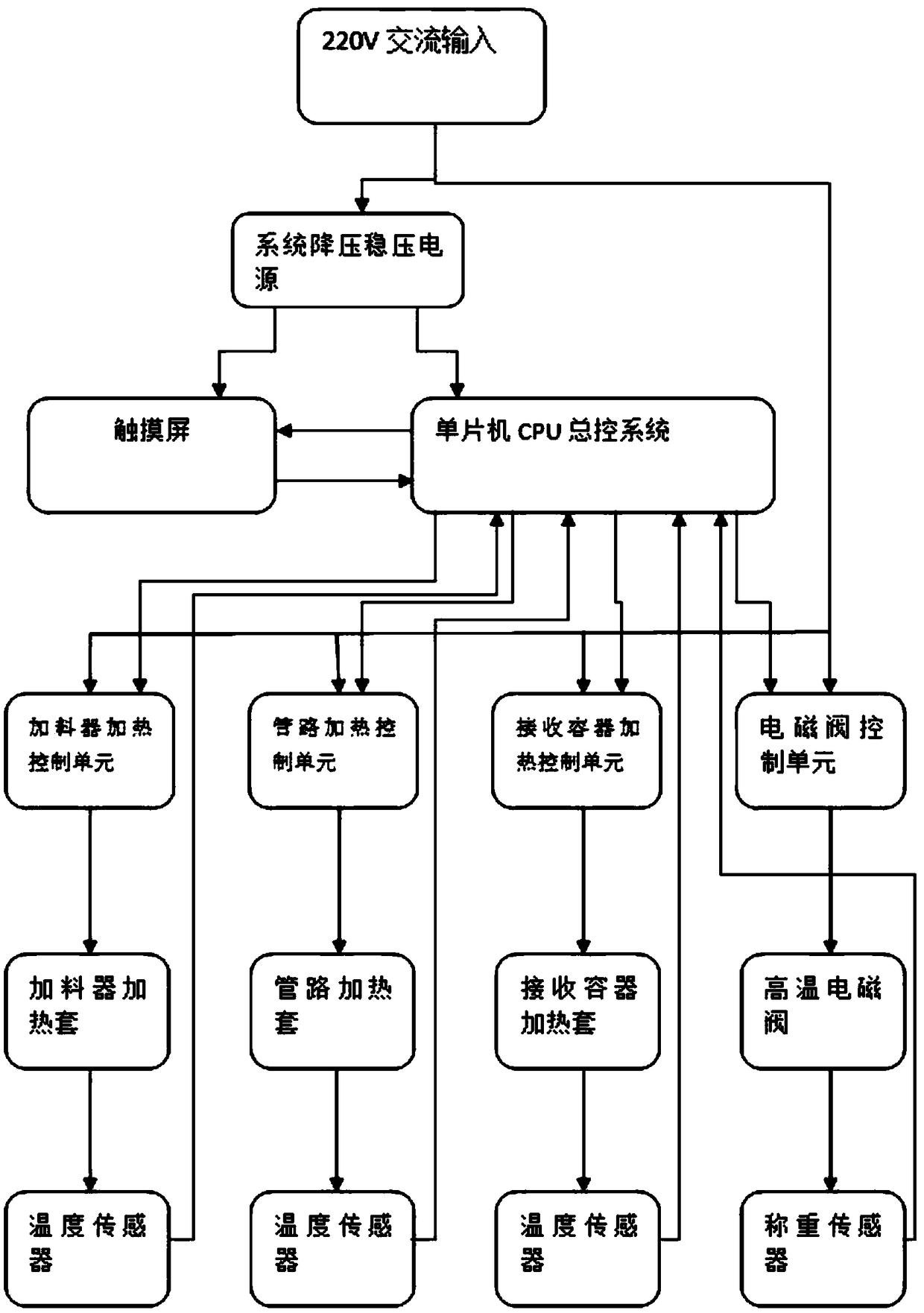

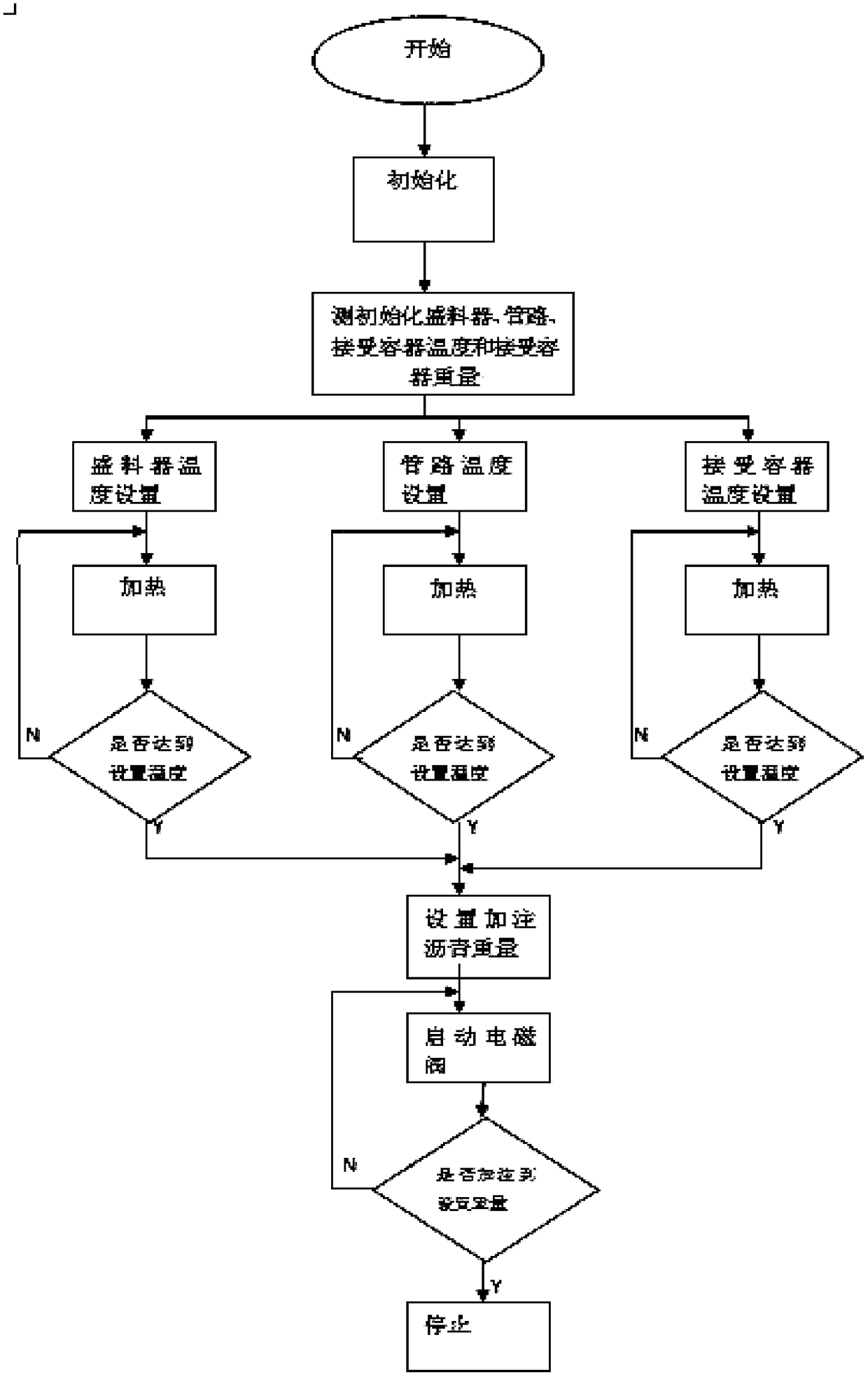

The invention discloses an automatic laboratory asphalt filling device. The device comprises a control mechanism and an execution mechanism connected with the control mechanism, wherein the control mechanism comprises a crate and an internal control system, the execution mechanism comprises a charging mechanism, a feeding mechanism and a storing mechanism, temperature sensors and heaters are arranged on the charging mechanism, the feeding mechanism and the storing mechanism respectively, a high temperature electromagnetic valve and a flowing nozzle are arranged on a feeding pipeline, a receiving insulating container is arranged on the storing mechanism, a clamp holder is arranged on the receiving insulating container, and the clamp holder is connected with a receiving bottle or a viscometer pipe. A laboratory asphalt filling process is automatically controlled, manual operation is not needed, through the temperature sensors and an automatic control device, heating temperature control is directly completed, through the electromagnetic valve and a weighing sensor, the weight of filled asphalt is controlled, by means of multiple control units in combination with a general control system, temperature control and heating process control are achieved separately, the efficient control requirements are met, and by setting the weighing sensor to control the filling weight, the requirements of automatically filling and measuring the laboratory asphalt are effectively met in the whole process.

Description

technical field [0001] The invention relates to the technical field of laboratory asphalt filling, in particular to a laboratory asphalt automatic filling device. Background technique [0002] Asphalt is a dark brown complex mixture composed of hydrocarbons of different molecular weights and their non-metallic derivatives. It is a kind of high-viscosity organic liquid. It is liquid with a black surface and is soluble in carbon disulfide. Asphalt is a waterproof, moisture-proof and anti-corrosion organic gelling material. Pitch can be mainly divided into three types: coal tar pitch, petroleum pitch and natural pitch: wherein, coal tar pitch is a by-product of coking. Petroleum asphalt is the residue after distillation of crude oil. Natural bitumen is stored underground, and some form ore layers or accumulate on the surface of the earth's crust. Asphalt is mainly used in coatings, plastics, rubber and other industries as well as paving roads. [0003] According to differen...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10C3/12G01N1/28

CPCG01N1/28C10C3/12

Inventor 钟洪卫陈桂梅何耀帮刘祖林

Owner CHANGSHA LUSHENG INSTR EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com