Labeling machine

A labeling machine and label feeding technology, which is applied in the direction of labeling machine, labeling, labeling, etc., can solve the problems of labeling machine with complex structure, large floor area and high operation requirements, and achieve compact structure, easy operation and reliable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

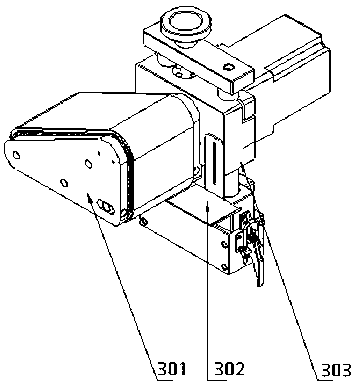

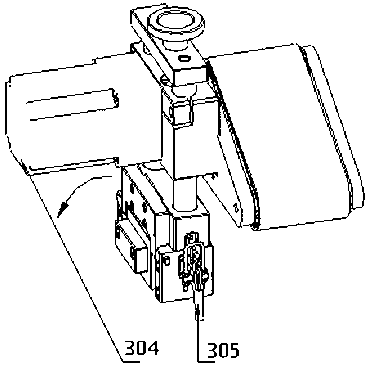

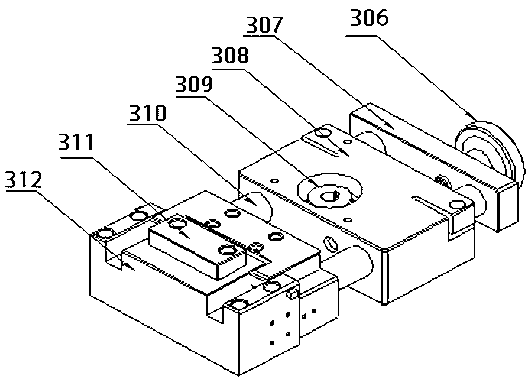

[0059] Such as Figure 4 As shown, a labeling machine includes a vertical-rotation-horizontal mechanical synchronous device 1, a roller conveyor belt 2, a synchronous bottle removal and bottle pulling device 9, and a bottle body horizontal-rotation-vertical device 8 connected in sequence. A bottle tape rolling device 7 is installed, and a label feeder 3 is also installed beside the bottle tape rolling device 7 so as to cooperate with the bottle tape rolling device 7 to complete labeling. Wherein, a printing machine 5 is also installed beside the label feeder 3 so as to be able to print on the material bottle. In addition, the label feeder 3 is installed on the double-bar adjustment bracket 4 so that the position can be adjusted, and a measuring device is installed next to the bottle tape device 7. Physical Eye 6.

[0060] The use method of the labeling machine is: when using, put the material bottle into the vertical-rotating-horizontal mechanical synchronization device 1, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com