Cigarette quality on-line detecting device of cigarette machine

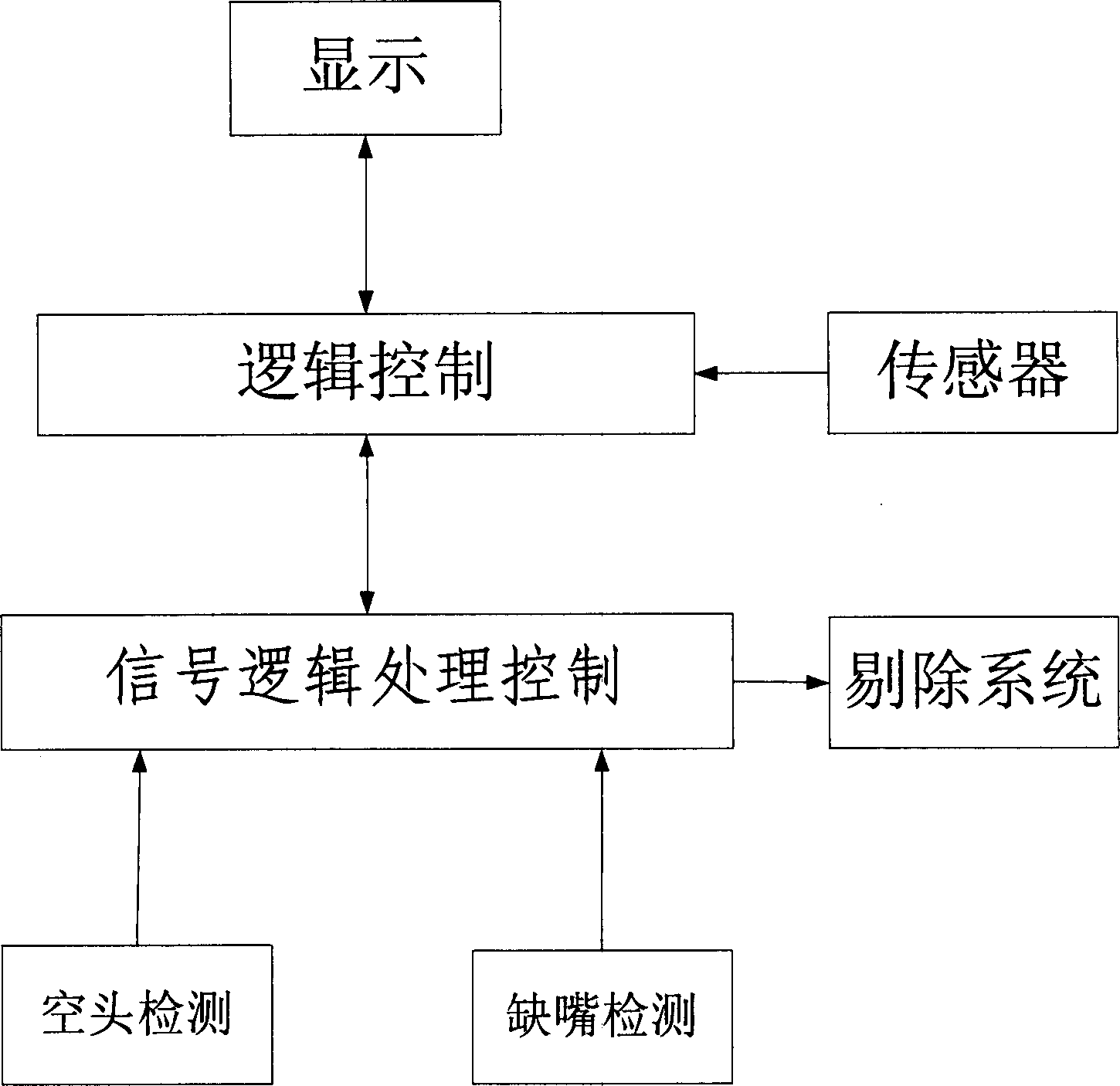

A detection device and cigarette technology, which are applied in the fields of tobacco, paper cigarette manufacturing, and application, can solve the problems of defective cigarettes entering the market, inability to eliminate drum wheels, poor stability, etc., so as to reduce the inflow of empty cigarettes and missing cigarettes. The effect of market, design rationality and reliability improvement, stability and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

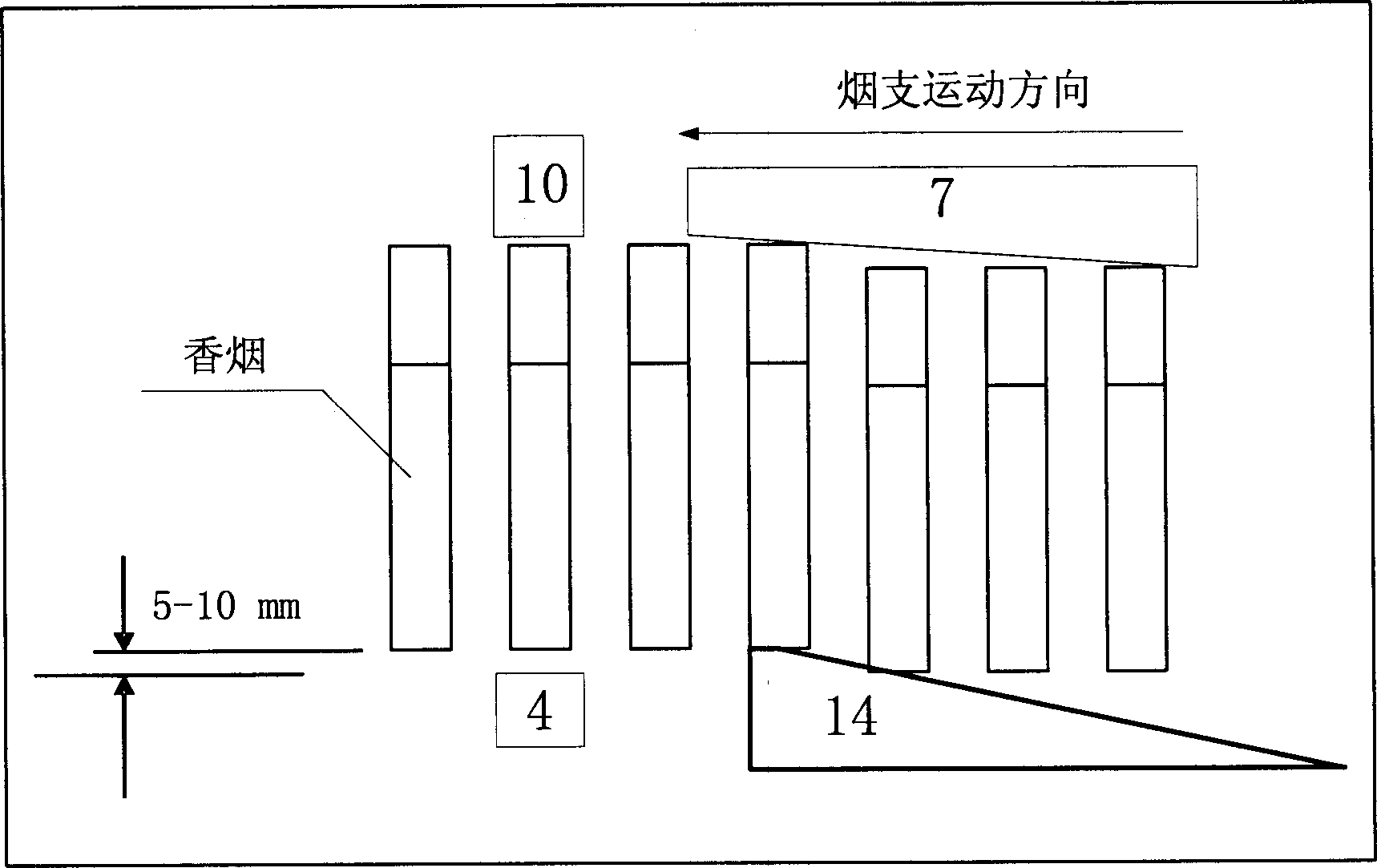

[0051] Embodiment is 8mm);

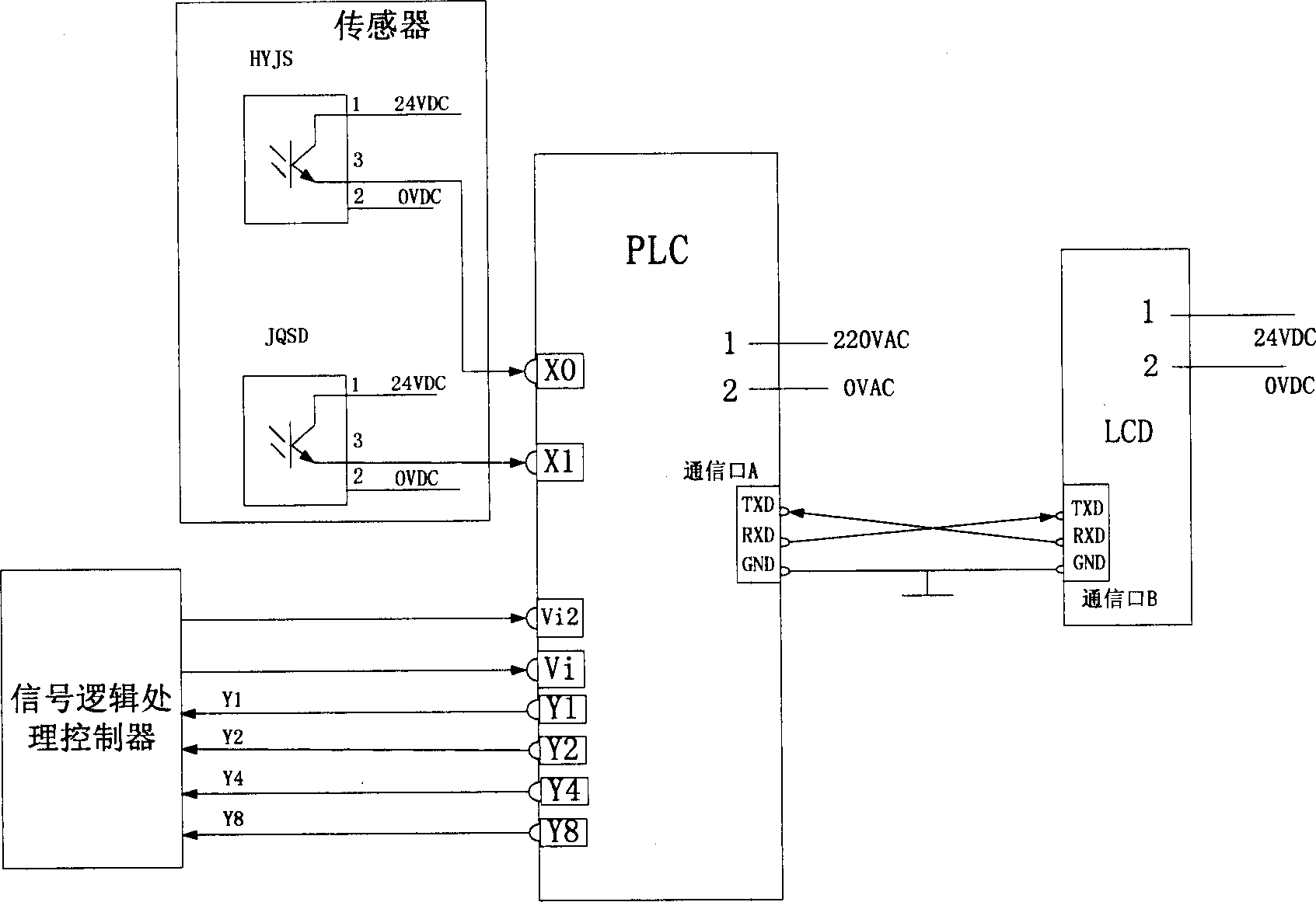

[0052] The signal logic processing controller is respectively controlled by signal logic processing and includes a signal gating unit, a synchronous setting unit, a signal sampling unit, a relative value setting unit, an absolute value setting unit, a comparison processing control output unit, and a shift and reject unit , remove the time unit, remove the driving part, switch the analog unit (such as Figure 4shown), in which the signal sampling unit collects and maintains the short signal of the cigarette, and then enters the comparison processing to control the output unit, and whether the signal sampling unit operates or not is determined by the opening and closing of the signal gating unit, and the synchronization setting unit uses Whether the signal gating unit is working or not. Because the collection of signals in the system of the present invention is concentrated at the burning end of the cigarette, this is a fixed-point, positioned data ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com