Robot sample sheet taking and placing and labeling and material frame buffering system and working method thereof

A caching system and robot technology, applied in the field of cold-rolled steel coil sampling and labeling in the steel industry, can solve the problems of high labor intensity, error-prone manual labeling, poor safety, etc., to improve the equipment level, improve the effective operation rate, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

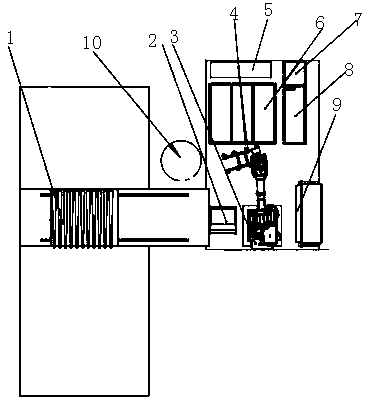

[0035] like figure 1 Shown: a system for robot taking and setting out, labeling and rack caching, which includes a mobile car 1, a robot control cabinet 2, a robot 3, a suction cup fixture 4, a PLC control cabinet 5, a buffer rack 6, and a labeling manipulator And printer 7, labeling station 8, manual loading and unloading station 9, sample cleaning and collection bin 10;

[0036] The mobile trolley, the robot control cabinet, the buffer rack, the labeling station, and the manual loading and unloading station are respectively located on both sides and the front of the robot, and the labeling station is provided with a labeling manipulator and a printer; the PLC control The cabinet is connected to the mobile trolley and controls it to move to the side of the robot. The PLC control cabinet is connected to the robot control cabinet and controls the robot to drive the sucker fixture to sample and stake out through the robot control cabinet. The PLC control cabinet is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com