Hard alloy composite roll

A cemented carbide, composite roll technology, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problem of frequent slot change, and achieve the effect of increasing the output of the rolling mill, improving the effective operation rate, and improving the wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

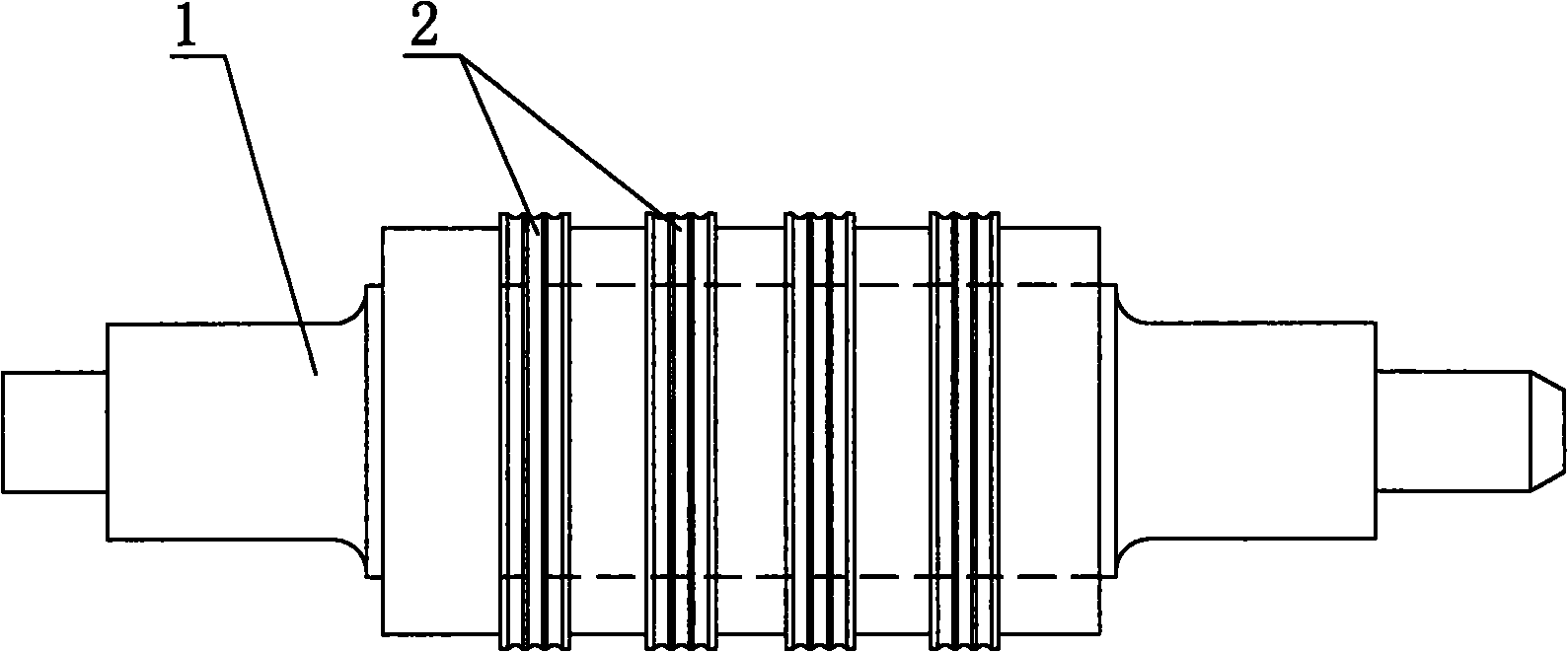

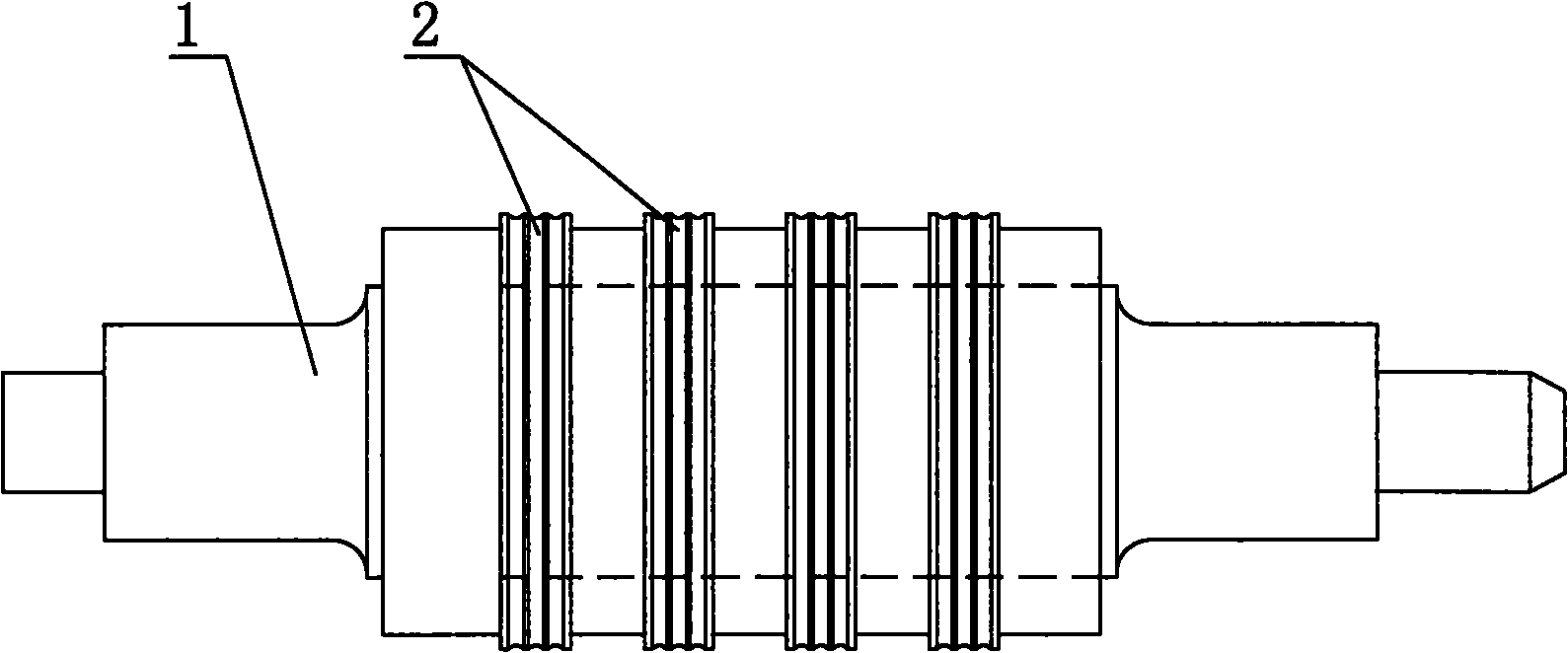

[0011] figure 1 Shown is the cemented carbide composite roll of the present invention, including a mandrel 1 and more than two roll rings 2, the roll rings 2 are sleeved on the mandrel 1, and the roll rings 2 are tungsten carbide cemented carbide For the roller ring, the mandrel 1 is made of ductile alloy steel. The tough alloy steel is 42CrMo or 40Cr or 40CrMo.

[0012] The roll ring 2 is in interference connection with the mandrel 1, and is manufactured into a combined bar mill finishing roll by a mechanical combination method. The cemented carbide composite roll hardness: 78 ~ 80HRA, specific gravity: 12.6 ~ 13.2kg / m 3 , bending strength ≥ 2000N / mm 2 . The maximum diameter of the roller ring is 470mm, and the scrapped diameter is 350mm.

[0013] Tungsten carbide cemented carbide has the characteristics of good thermal conductivity (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com