Mechanical pushing mechanism capable of realizing separate pushing

A push mechanism and mechanical technology, applied in the direction of packaging cigarettes, etc., can solve the problems of increased production cost, shutdown, and reduced effective operation rate of the machine, and achieve the effect of reducing production cost and improving effective operation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

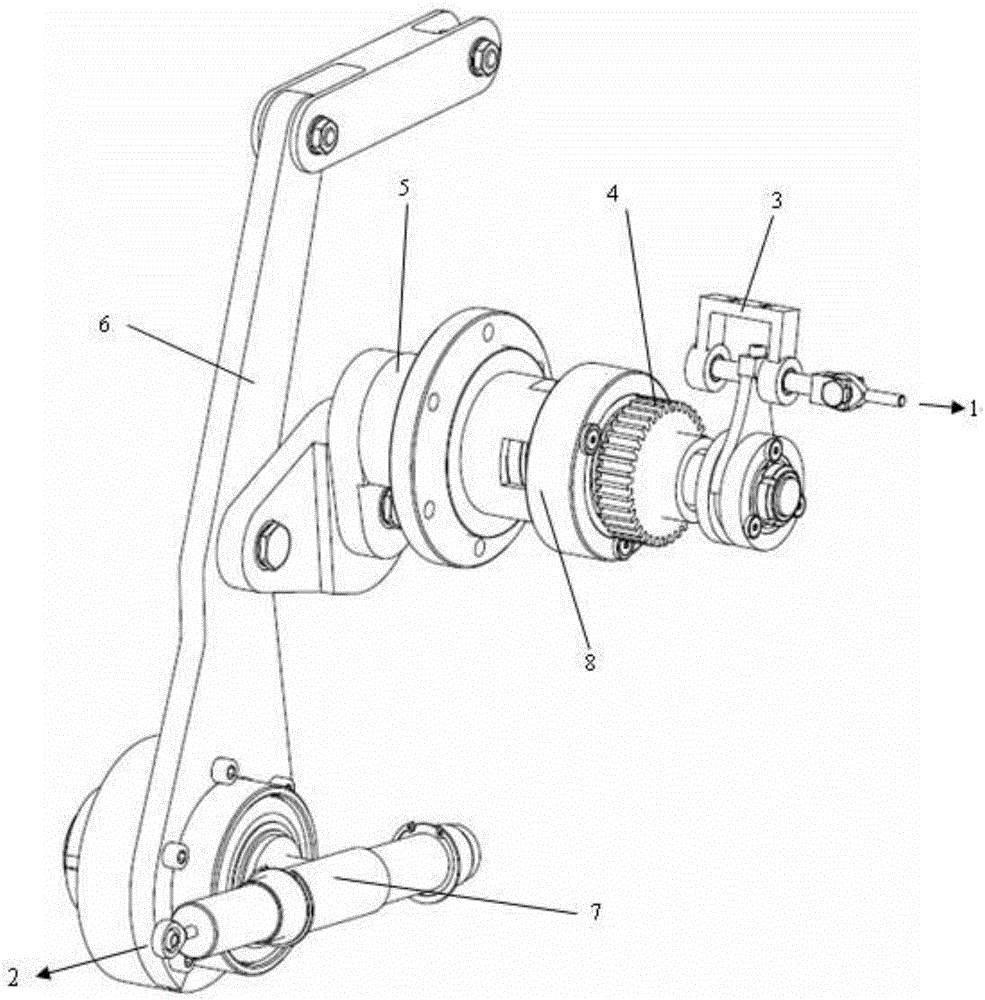

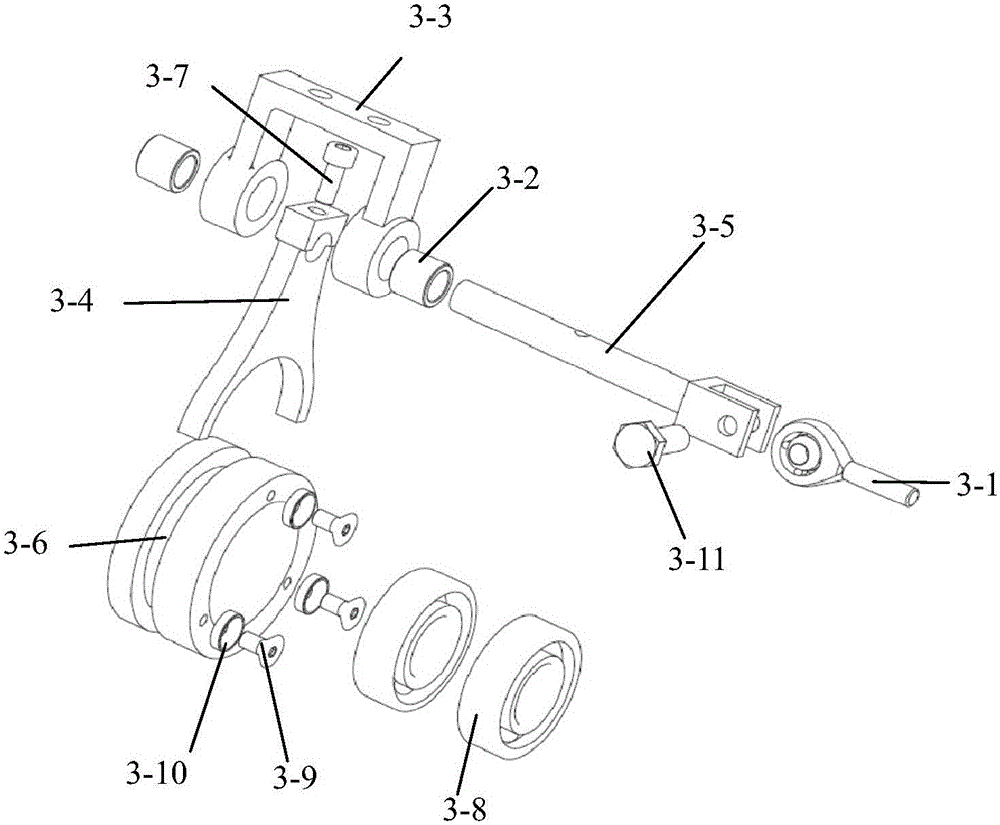

[0059] Such as figure 1 As shown, the present invention can realize a mechanical push mechanism for separate push, including a first oil cylinder 1, a shift fork assembly 3, a drive shaft assembly 4, a driven shaft assembly 5, a crank rocker assembly 6, a support shaft assembly 7, and a flange The sleeve assembly 8, the second oil cylinder 2, the shift fork assembly 3 is connected to the first oil cylinder 1; the shift fork 3-4 of the shift fork assembly 3 is connected to the drive shaft 4-2 of the drive shaft assembly 4; the first oil cylinder 1 can pass through the shift fork assembly 3 drives the drive shaft 4-2 to reciprocate in the axial direction;

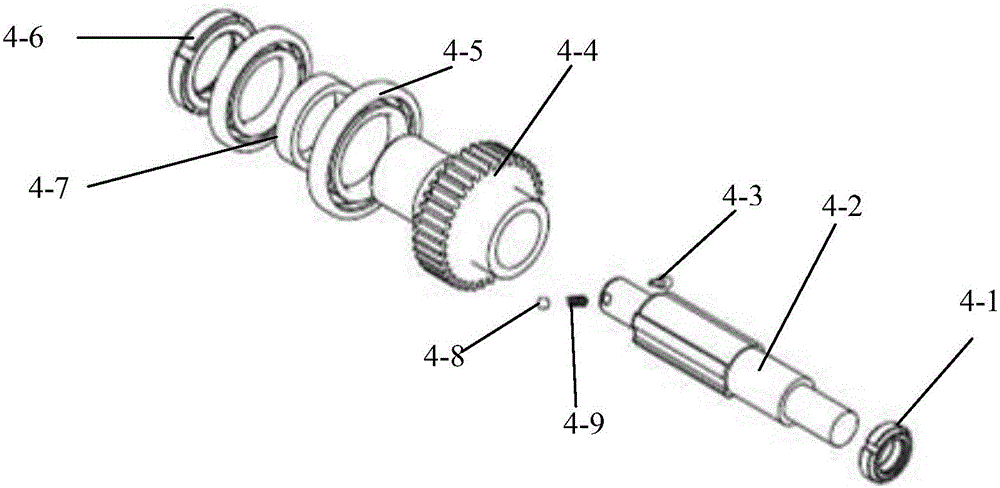

[0060] The drive shaft assembly 4 is arranged at the rear end of the flange sleeve assembly 8, and the front end of the flange sleeve assembly 8 is provided with a driven shaft assembly 5; the driven shaft 5-1 of the driven shaft assembly 5 can only rotate but cannot move axially ; The drive gear 4-4 of the drive shaft assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com