Automatic drying system of monochromatic gravure press

A technology of drying system and gravure printing machine, applied in the direction of gravure rotary printing machine, printing machine, rotary printing machine, etc., can solve the problems of restricting the effective use of equipment, product sticking, destroying pattern effect, etc., to improve the effective operation of equipment rate, product qualification rate rise, the effect of improving the qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

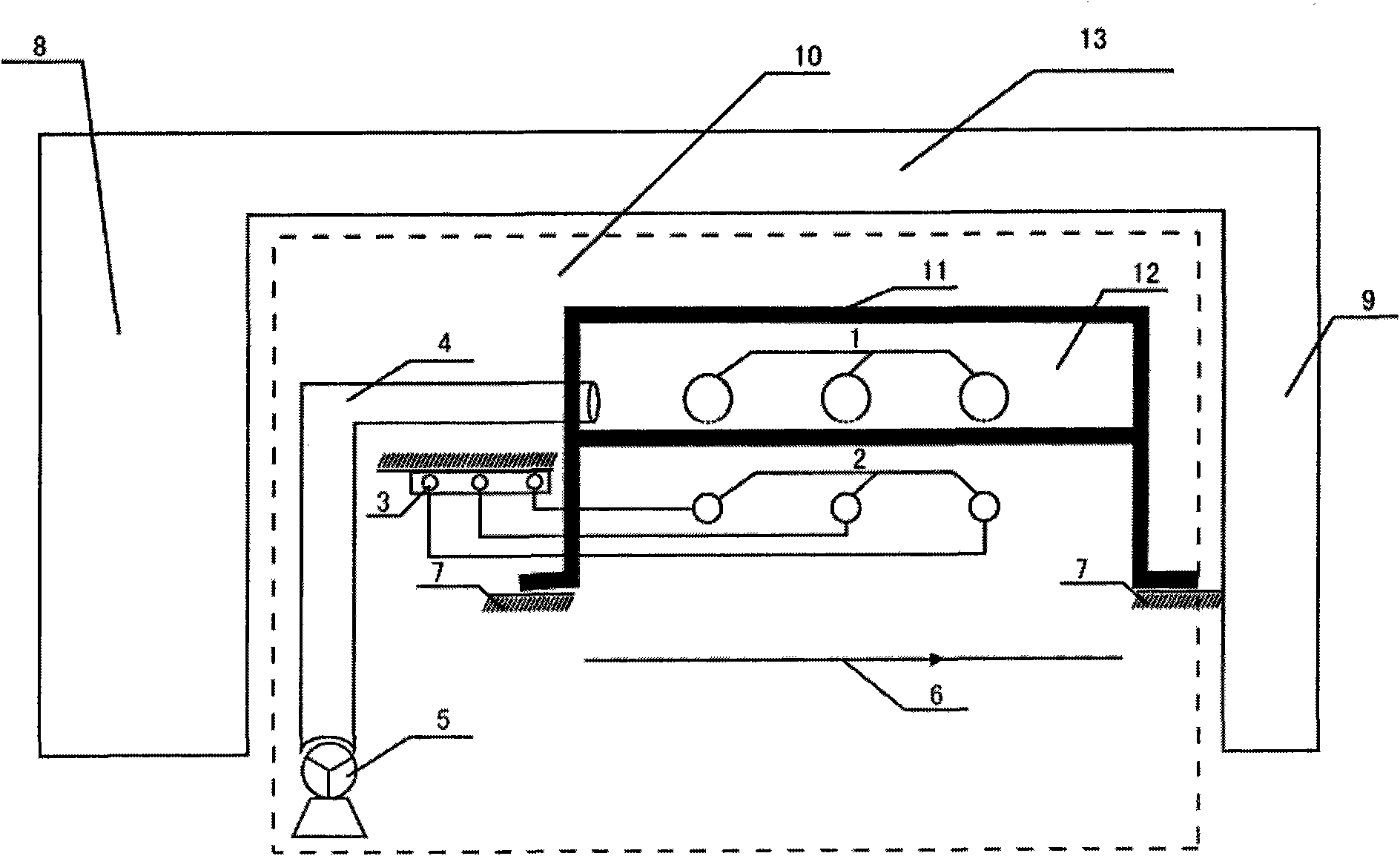

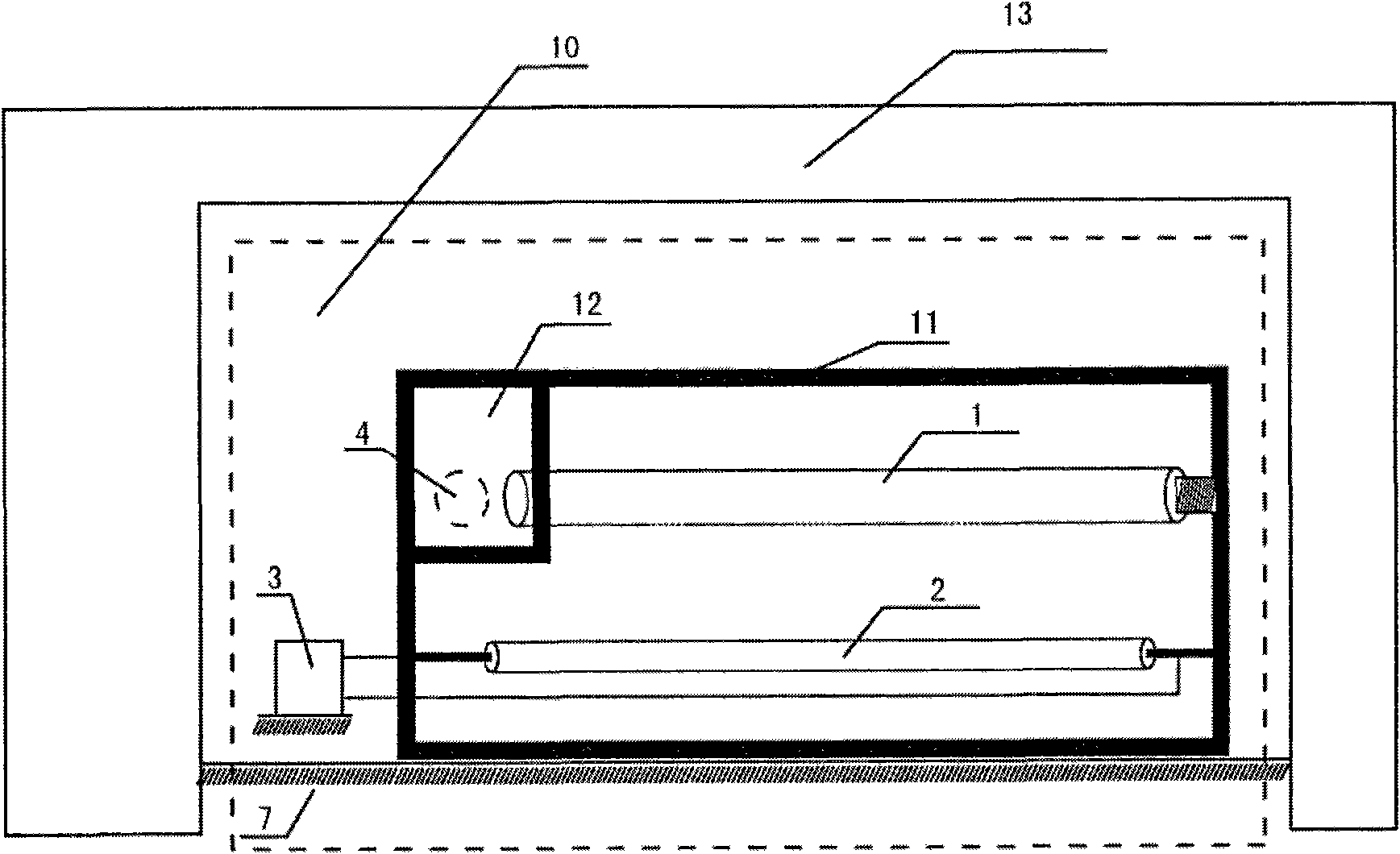

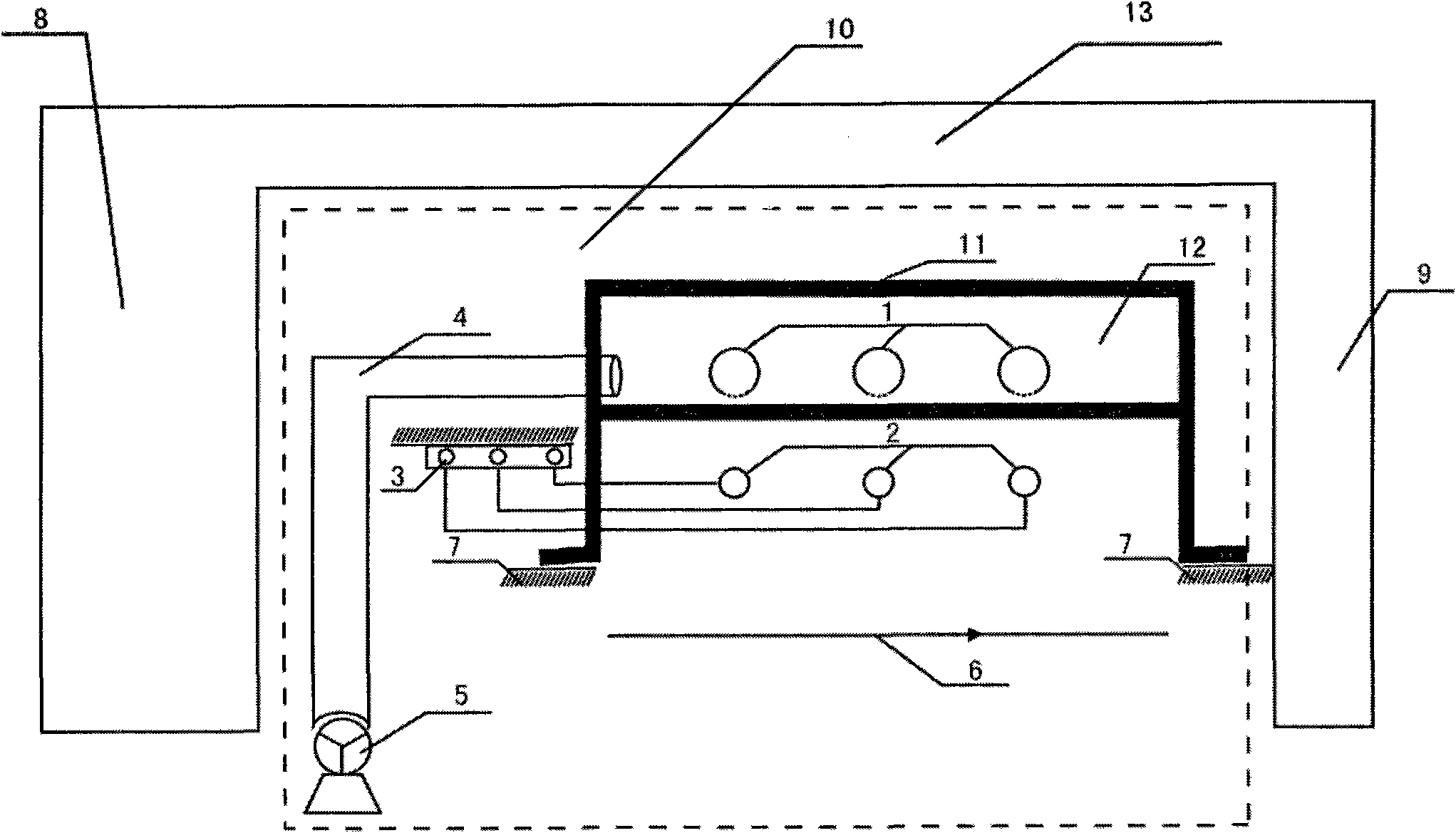

[0009] Such as figure 1 , figure 2 As shown, the present invention is equipped with an automatic drying system 10 on the frame 13 between the printing part 8 and the delivery part 9, and the machine cover 11 of the automatic drying system 10 is installed on the slideway 7 on the frame 13, It can slide in and out on the frame 13, which is convenient for replacing and cleaning the air duct 1 and the infrared lamp tube 2; the shared air duct 12 of the machine cover 11 communicates with the main air duct 4, and the fan 5 with the motor communicates with the main air duct 4 connection, the wind in the main air duct 4 blows into the three air ducts 1 with holes at the bottom, the air ducts 1 are fixed on the hood 11, and the lower part of the air duct 1 in the hood 11 is equipped with three infrared lamps 2 , Infrared lamp tube 2 is fixed on the hood 11, and infrared lamp tube 2 is controlled by 3 air-break switches 3 installed on the frame 13 to break it respectively.

[0010] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com