Method for measuring distance between rollers in rolling mill

A roll and rolling mill technology, which is applied in the direction of length measuring device, metal rolling, metal rolling, etc., can solve the problems of large error, piled steel accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0022] The present invention provides a method of measuring the distance between rolls in a rolling mill, the method comprising:

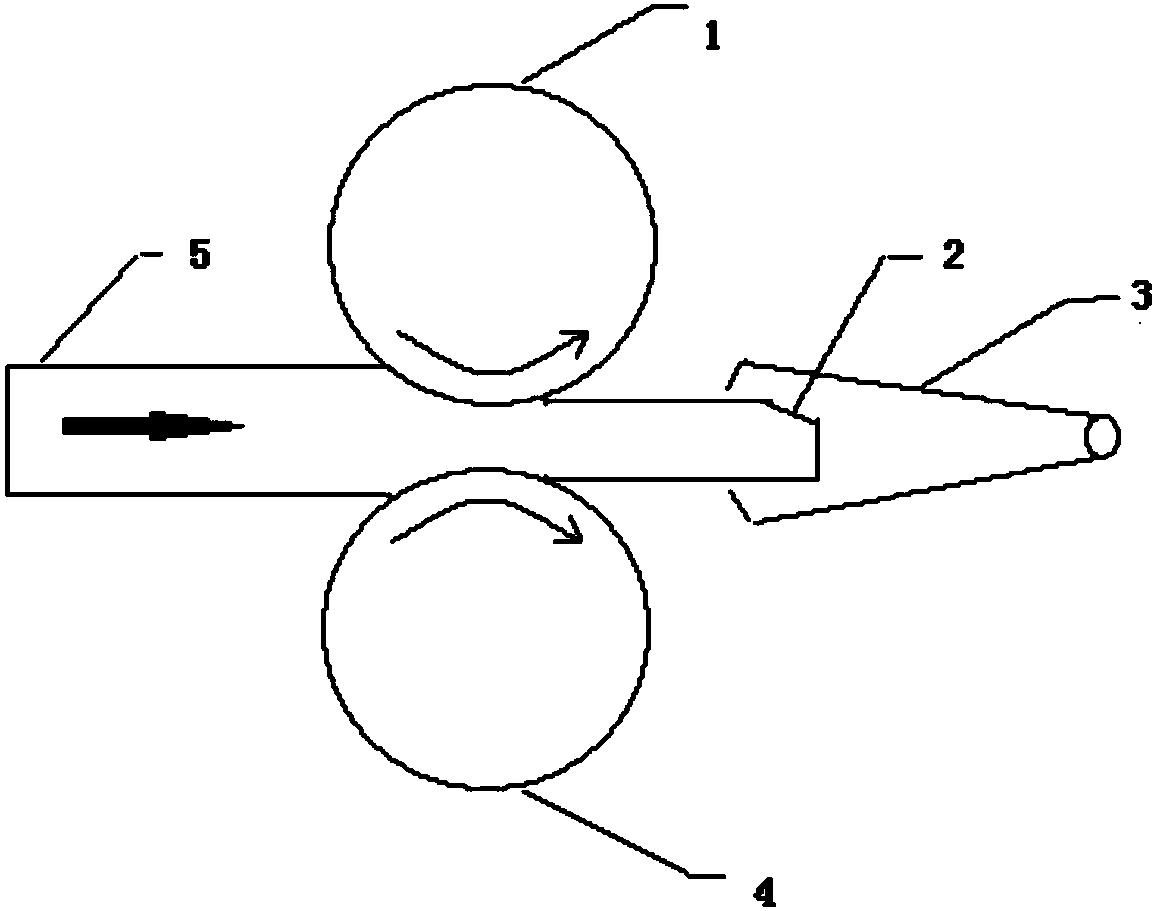

[0023] (1) Prepare the pre-rolled sample 5, heat the pre-rolled sample 5, and then turn on the rolling mill, so that the heated pre-rolled sample 5 is rolled by the upper roll 1 and the lower roll 4 to obtain a rolled sample;

[0024] (2) Use the caliper 3 to measure the thickness of the rolled sample to obtain the distance between the upper roll 1 and the lower roll 4 . By using the method of pressing small samples before driving through the steel, the steel material during rolling can be simulated, and the size of the small steel sample can be accurately measured, so as to ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com