Beating roller for defoliator

A technology of leaf topper and roller, which is used in the treatment of tobacco, tobacco, application, etc., can solve the problems of easy breakage of fixed parts, reduced production efficiency, slippage of the turntable, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

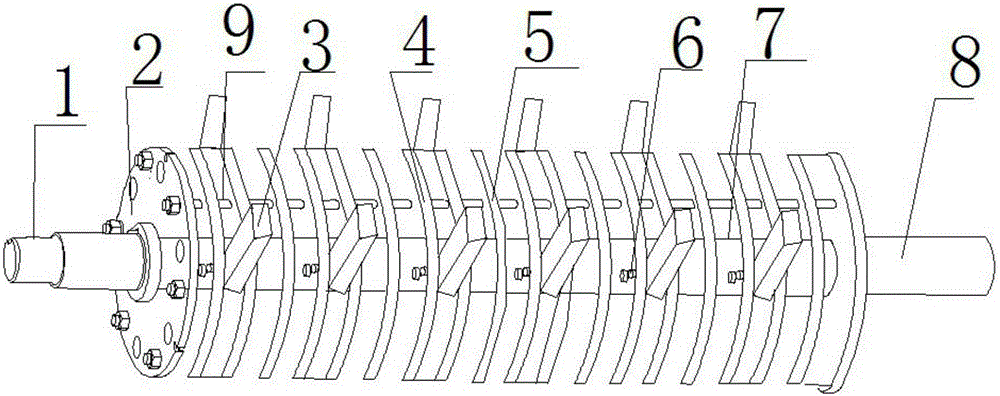

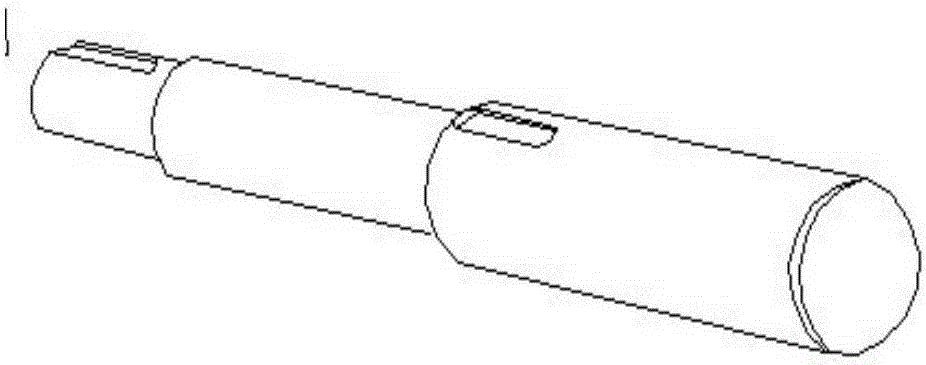

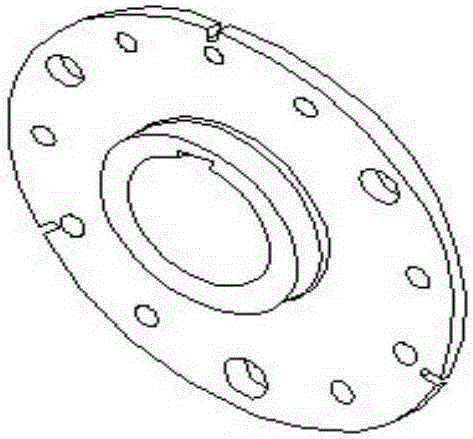

[0023] Such as figure 1 As shown, the present invention discloses a leaf topper roller, which includes a pulley end shaft 1, an end shaft 8, a roller end cover 2, a spacer knife disc 5, a knife disc 4, a roller 7, and a knife 3 , locating pin 6, pull rod 9, and the roller end cover 2 has two before and after, the pulley end shaft 1 is positioned at the front end of the integral roller end, the tail end of the pulley end shaft 1 is inserted into the center of the roller end cover 2, and the cutter head 4. The spacer cutter disc 5 is set on the roller 7, and a spacer cutter disc 5 is arranged between every two knife discs 4. The knife 3 uses positioning pins 6 to fix the tail of the knife 3 on the two knife discs. Between the cutter heads 4, there ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com