Three-roller pipe rolling apparatus

A three-roll rolling and tube mill technology, applied in the direction of metal rolling stands, metal rolling mill stands, rolls, etc., can solve the problems of affecting product quality, many equipment adjustment links, tail triangles, etc., so as to reduce rolling failures. Equipment factors, improve the effective operation rate, and improve the effect of adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

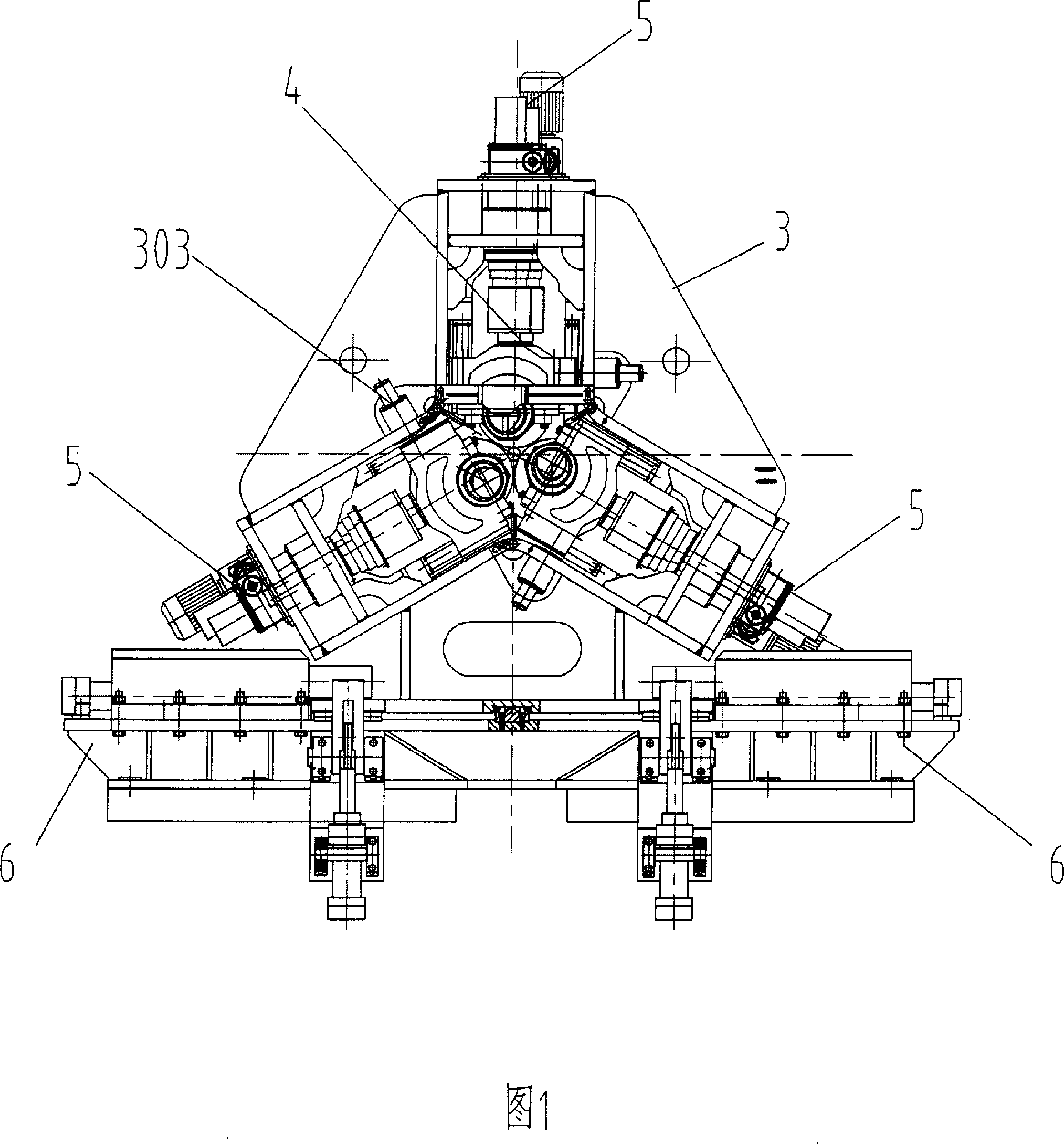

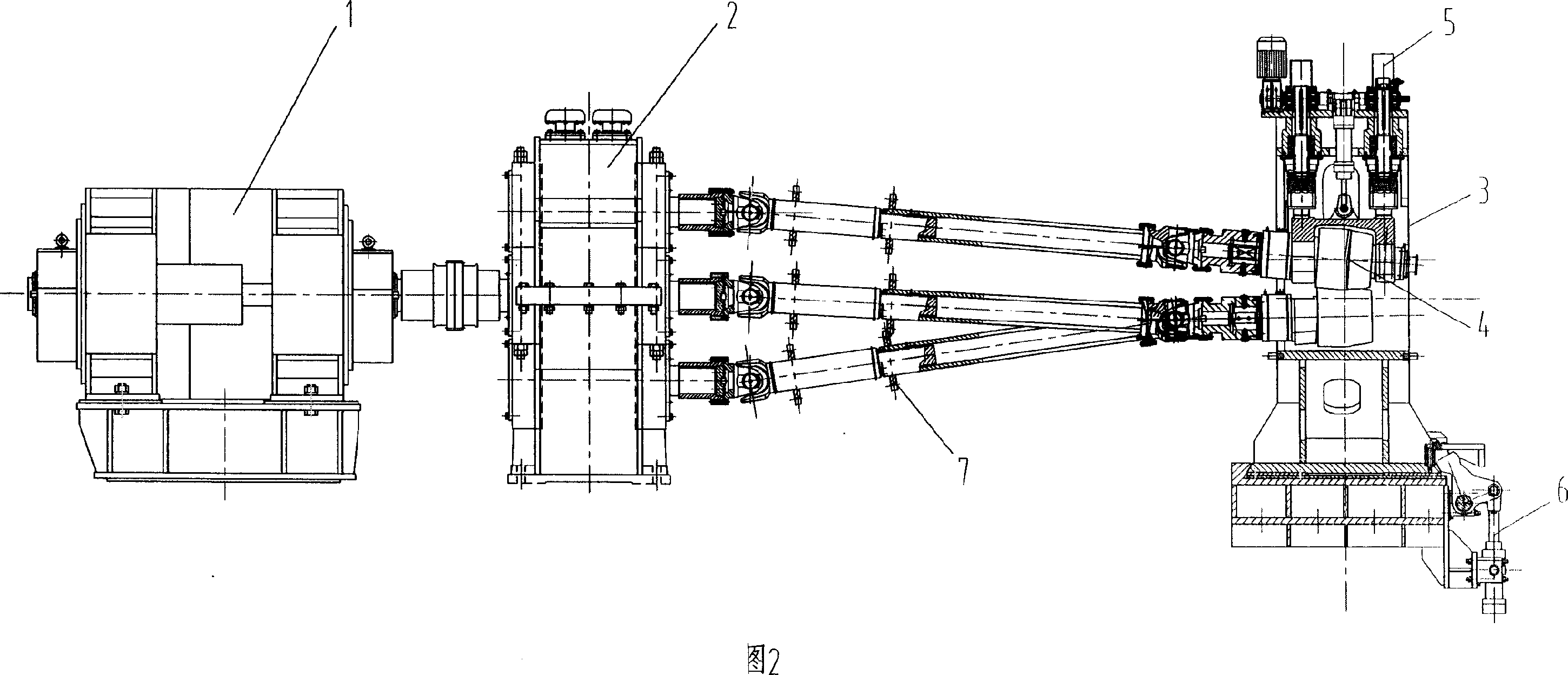

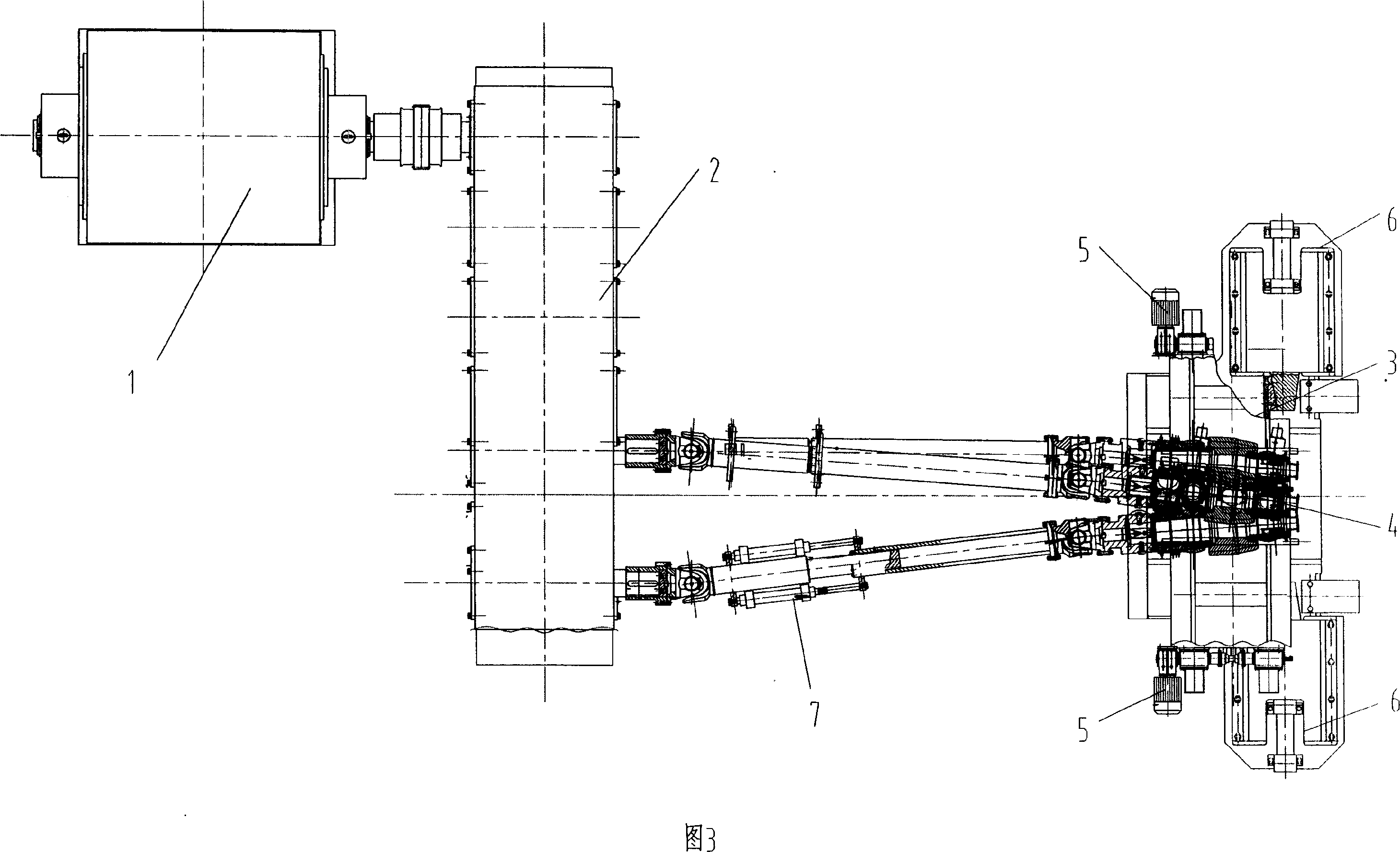

[0043] Shown in Fig. 1, Fig. 2 and Fig. 3, the three-roll pipe rolling mill of the present invention. It includes a motor 1, a transmission device 2, a welded closed frame 3, three sets of roll box devices 4 in the frame, and three sets of transmission and balance devices 5 for adjusting the pressure of the rolls; the frame and the base can be separated, and the frame The frame base and the push-pull and locking device 6 are arranged under the frame, and the frame is fixed on the base by the push-pull locking device; It is equipped with quick connectors with peripheral lubricating equipment, and the interface between electrical equipment and peripheral power supply and control equipment is also equipped with quick sockets. The transmission device 2 is commonly composed of a shaft coupling, a final reducer, a universal joint shaft, and the lik...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com