Same-rail double-crossing vehicle intelligent scheduling method

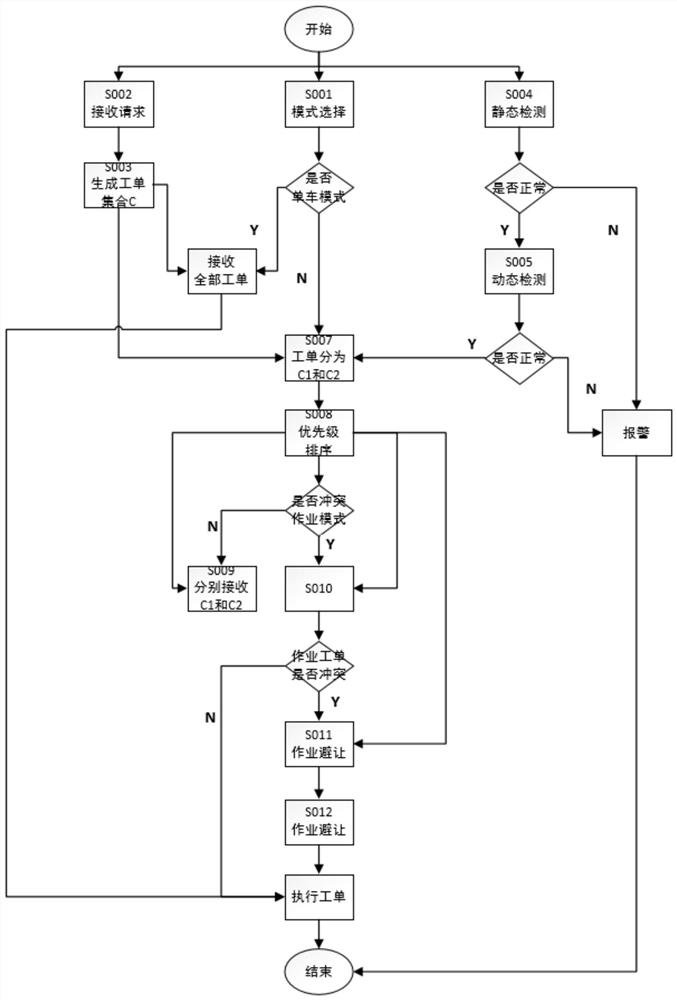

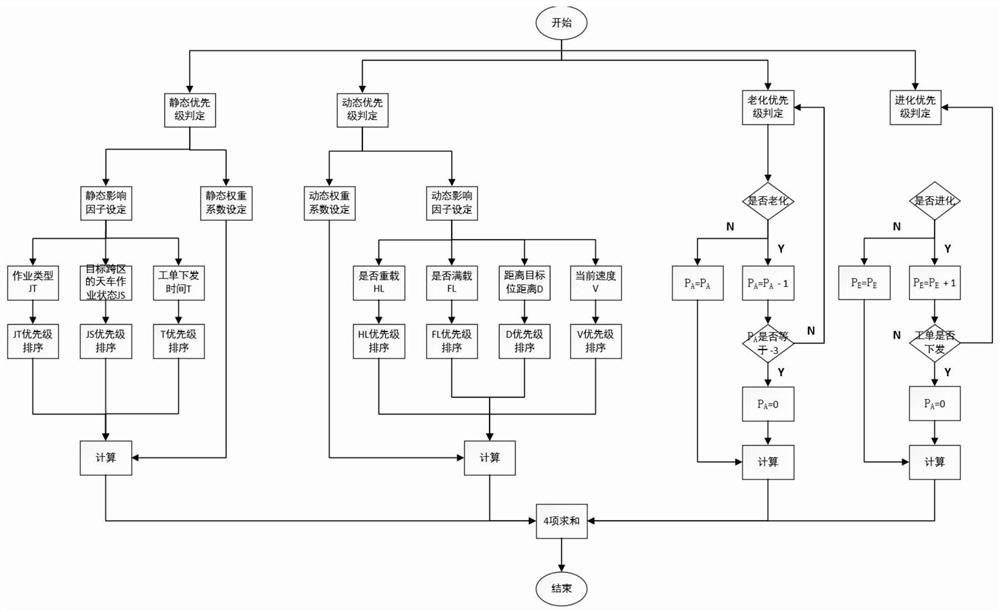

An intelligent dispatching and straddle-car technology, applied in the field of logistics equipment control, can solve the problem that manual dispatching control cannot meet the operation requirements, etc., and achieve the effect of shortening the waiting time, running without conflict, and reducing the probability of emergency stop due to conflict.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

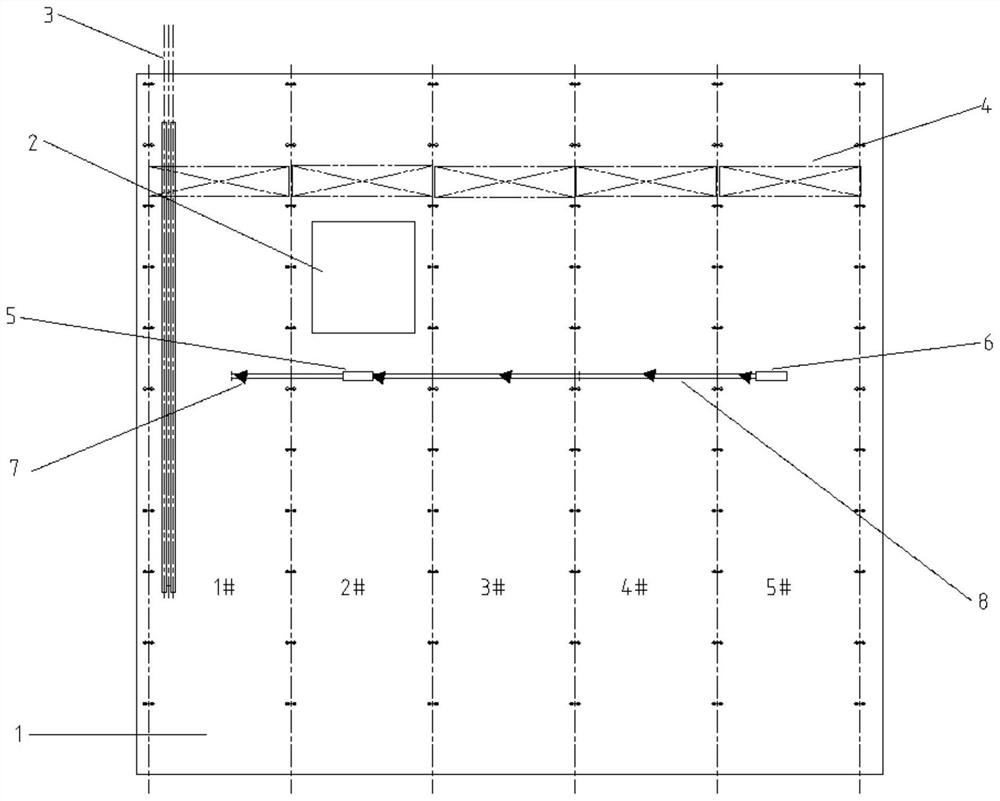

[0060] Taking a certain hot-rolling storage area as an example, such as figure 2 As shown, the reservoir area has 5 crossing areas, which are 1#, 2#, 3#, 4#, 5# from west to east, 1# is cold rolling raw material spanning, 2# is flat raw material spanning, 3#~ 5# is the finished product warehouse (all with delivery function), each span is 42 meters long, each span area has a crane, and the entire warehouse area has two left span cars and right span cars on the same track, each span Each straddle has 2 saddles. Assuming that each cross-region has a request for coil transportation, 1# is for cold rolling on-line, 2# is for leveling on-line, 3# is for second-layer coil reversion, 4# is for delivery, and 5# is for daily storage. The 1# crane takes up the coil, the 2# crane takes the coil down, the 3# crane unwinds down, the 4# crane unwinds up, and the 5# crane is free. The straddle car on the left is fully loaded, and it is currently running at high speed; the straddle car on t...

Embodiment 2

[0068] Taking a certain hot-rolling storage area as an example, such as figure 2 As shown, the reservoir area has 5 crossing areas, which are 1#, 2#, 3#, 4#, 5# from west to east, 1# is cold rolling raw material spanning, 2# is flat raw material spanning, 3#~ 5# is the finished product warehouse (all with delivery function), each span is 42 meters long, each span area has a crane, and the entire warehouse area has two left span cars and right span cars on the same track, each span Each straddle has 2 saddles. Assuming that each cross-region has a request for coil transportation, 1# is for cold rolling on-line, 2# is for leveling on-line, 3# is for second-layer coil reversion, 4# is for delivery, and 5# is for daily storage. The 1# crane takes up the coil, the 2# crane takes the coil down, the 3# crane unwinds down, the 4# crane unwinds up, and the 5# crane is free. The straddle car on the left is fully loaded, and it is currently running at high speed; the straddle car on t...

Embodiment 3

[0092] Taking a certain hot-rolling storage area as an example, such as figure 2 As shown, the reservoir area has 5 crossing areas, which are 1#, 2#, 3#, 4#, 5# from west to east, 1# is cold rolling raw material spanning, 2# is flat raw material spanning, 3#~ 5# is the finished product warehouse (all with delivery function), each span is 42 meters long, each span area has a crane, and the entire warehouse area has two left span cars and right span cars on the same track, each span Each straddle has 2 saddles. Assuming that each cross-region has a request for coil transportation, 1# is for cold rolling on-line, 2# is for leveling on-line, 3# is for second-layer coil reversion, 4# is for delivery, and 5# is for daily storage. The 1# crane takes up the coil, the 2# crane takes the coil down, the 3# crane unwinds down, the 4# crane unwinds up, and the 5# crane is free. The straddle car on the left is fully loaded, and it is currently running at high speed; the straddle car on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com