Automatic control device for correcting tipping paper of plug assembler

An automatic control device, tipping paper technology, used in the tobacco industry. It can solve problems such as hidden dangers of cigarette quality, high rate of consumption and waste of cigarettes, and large amount of cigarettes removed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

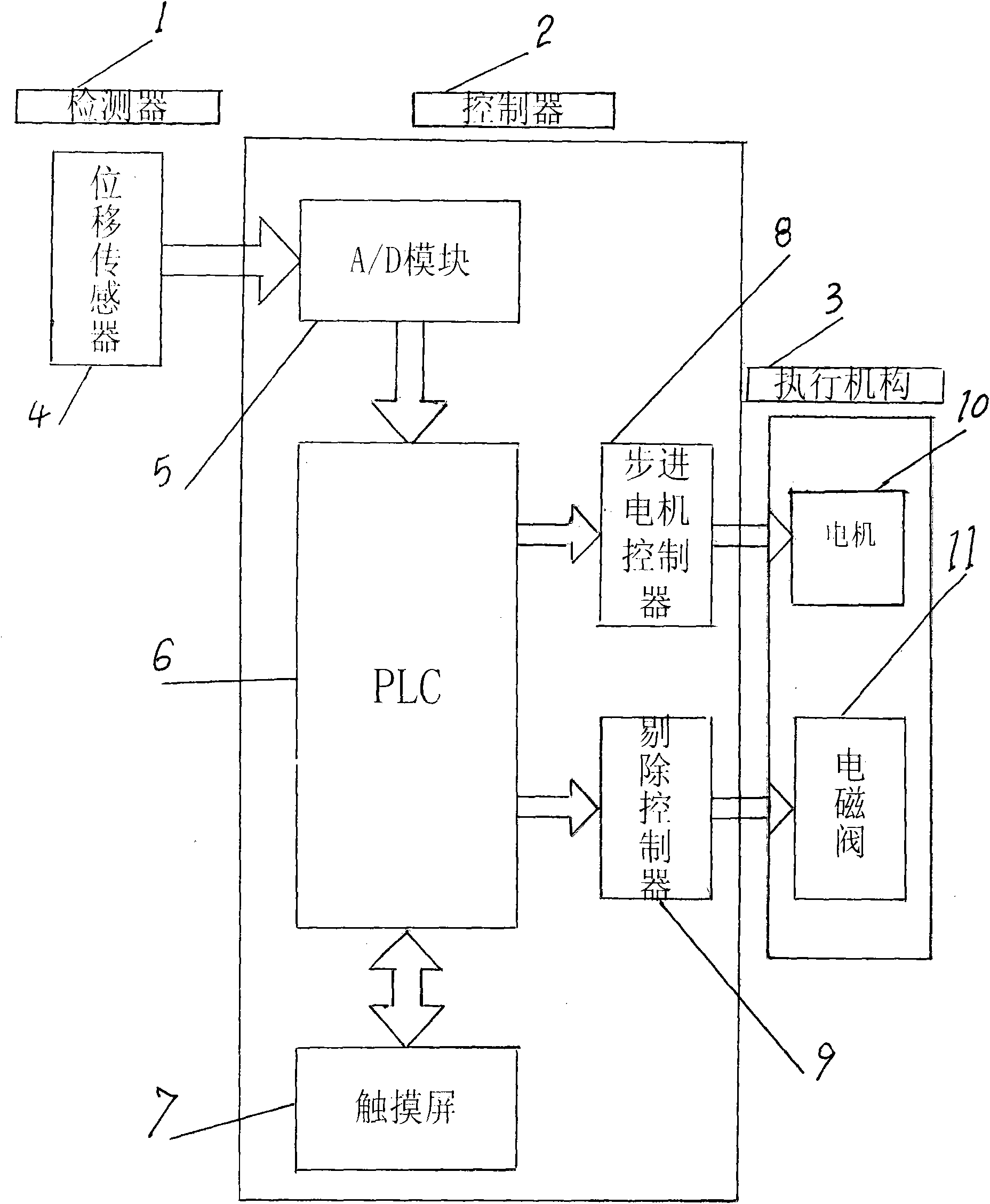

[0006] The embodiment is described in detail in conjunction with the accompanying drawings. The present invention uses the detector 1, the controller 2 and the actuator 3 to complete the correction of tipping machine tipping paper. At the position in front of the paper drum, the displacement sensor 2 is a high-precision reflective KEYENCE sensor. This sensor has an analog input and can be directly connected to the A / D conversion module 5 to provide a signal to the PLC 6. The displacement sensor 6 receives the tipping paper After the deviation signal is output, the A / D module installed on the controller 2 processes and converts it into a digital quantity and transmits it to the PLC6, and the PLC outputs the signal after processing, and the stepping motor controller 8 and the rejecting controller 9 installed on the actuator 3 Receive and feed back the operation information to the touch screen 7 for display. On the touch screen 7, you can set the offset of rejection and shutdown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com