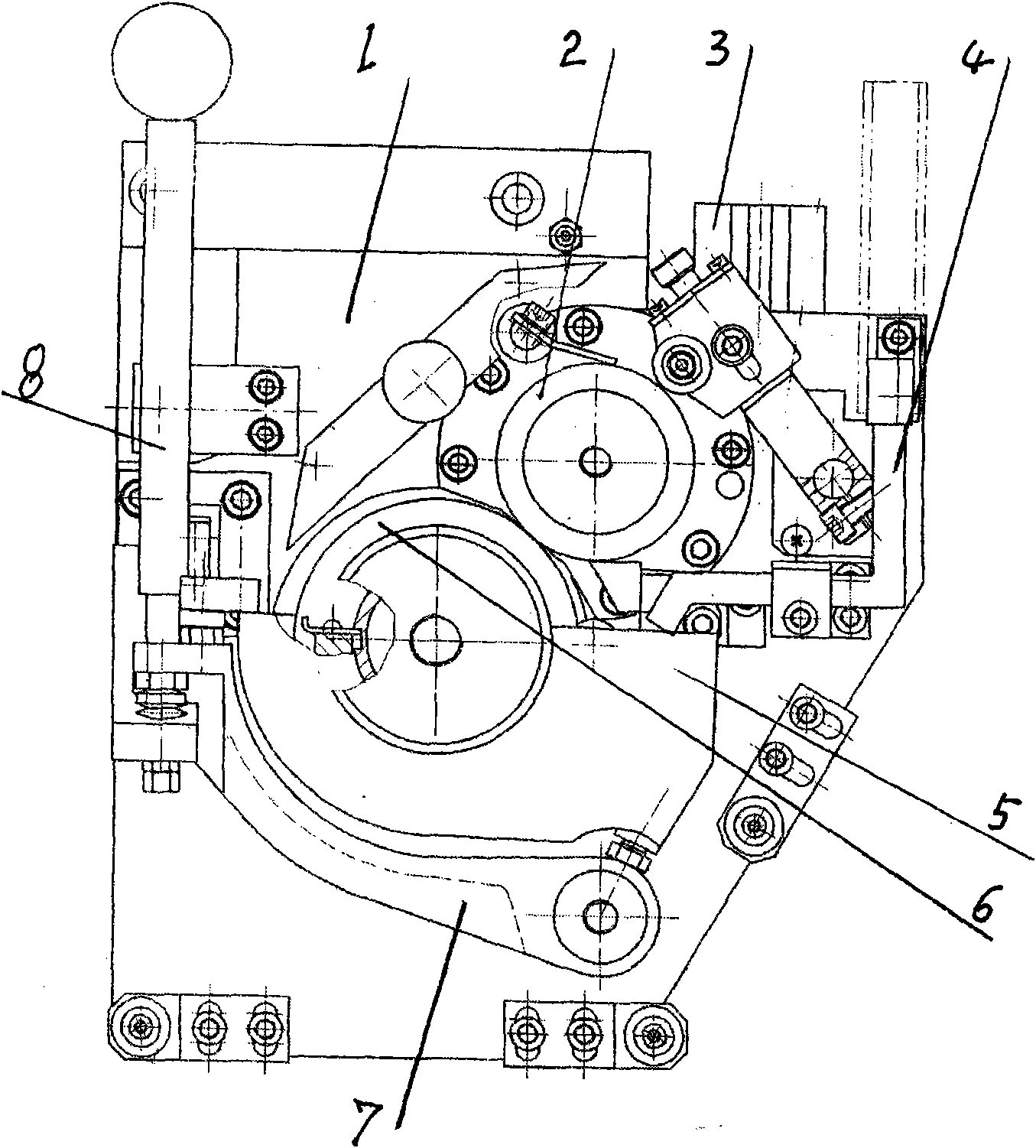

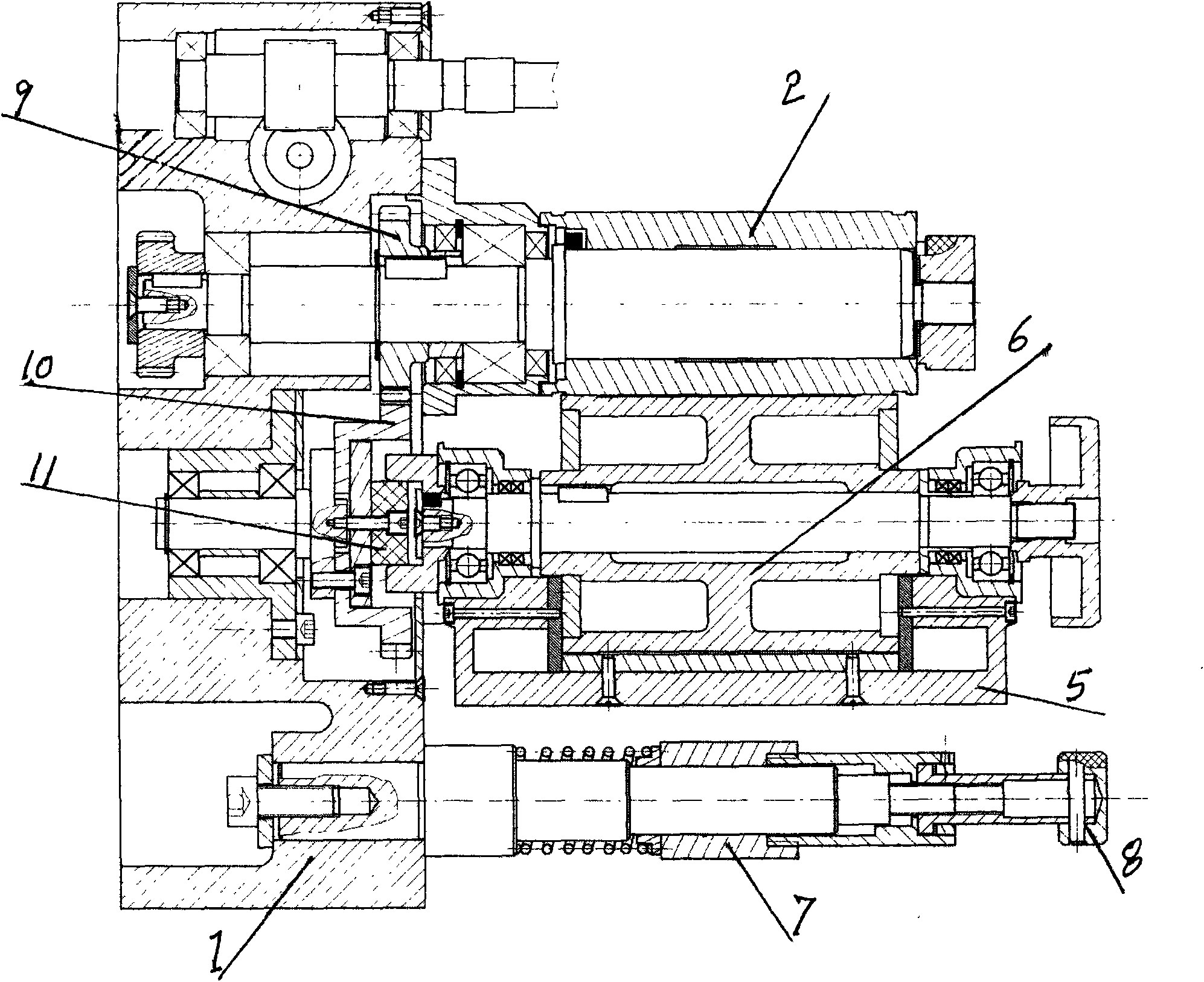

Glue feed mechanism on cigarette making machine

A technology for cigarette making machine and glue supply, which is applied in the directions of tobacco, cigarette manufacturing, and devices for coating liquid on the surface, etc., and can solve problems such as air leakage, full glue, latex pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The embodiment is described in detail in conjunction with the above drawings. The present invention uses an imported diaphragm pump to supply glue. The upper rubber shaft 2 is installed on the box body 1 and is directly driven by the main shaft. The lower rubber roller 6 is supported on the glue tank 5 through the sealed bearings at both ends of the shaft. The upper part of the rubber cylinder 5 is equipped with a rubber surface detection photocell, and a pair of gears are respectively connected to the rear of the upper and lower rubber rollers. The upper rubber roller gear 9 and the lower rubber roller gear 10 are meshed for transmission. The rubber roller gears 10 are connected by a slider coupling 11, the shaft of the curved arm 7 of the box 1 is equipped with an adjustment handle 8, and the cylinder 3 is installed on the side of the box 1 to drive the gear through the rack on it. The lower part of the roller periphery of the lower rubber roller 6 is buried in the rub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com