Improved structure of small box cigarette packer seal label conveying structure

The technology of box packaging and conveying wheel is applied in the field of sealing and conveying structure devices of small box packaging machines, which can solve the problems affecting the effective operation rate of equipment, unstable and improving the conveying of seals, etc., so as to improve the effective operation rate and strong adaptability. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

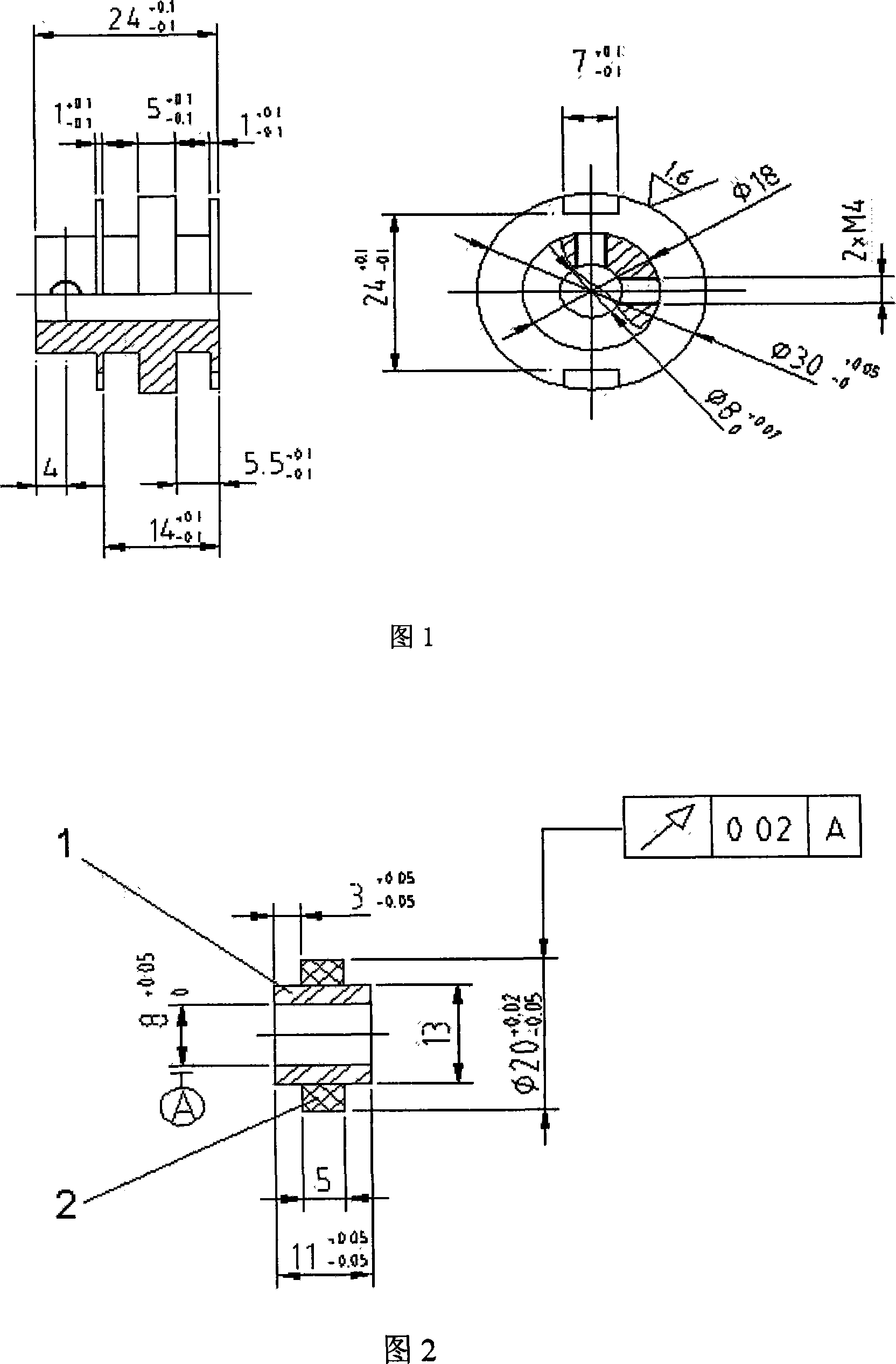

[0015] The present invention aims at the existing problems of the original seal conveying parts, and adopts the following method to improve the conveying wheel and conveying roller, see Fig. 1 and Fig. 2 .

[0016] (1) According to the size of the gluing counter-pressure wheel, the gluing conveying wheel is designed as a cylindrical conveying wheel with a width of 5mm and a diameter of 24mm. Since the width is just matched with the pair of pressure wheels, the contact surface between the two is greatly increased, so the wear speed of the two wheels is greatly reduced; at the same time, the increase of the contact surface makes the sensitivity of the wear of individual points on the contact surface to the influence of the seal conveying also reduced. Therefore, it can be ensured that the delivery stability of the rubberized conveying wheel made by the invention is greatly improved while the service life is extended.

[0017] (2) The seal conveying roller is made of polyurethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com