Gluing device for aluminum shell cover plate of power capacitor

A technology for power capacitors and gluing devices, which is applied in the directions of packaging capacitor devices, capacitors, and capacitor manufacturing, etc., can solve the problems of hidden safety hazards, uneven coating levels, and poor sealing effect of power capacitors, so as to ensure the service life, The effect of sufficient glue and good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

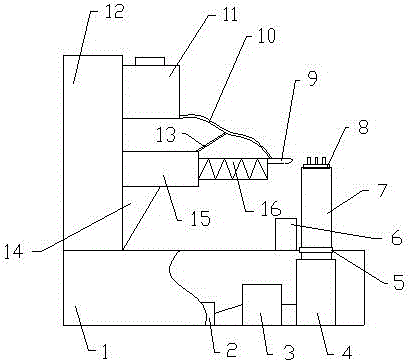

[0014] In order to make the technical means, creative features, goals and effects of the invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0015] Such as figure 1 As shown, a power capacitor aluminum shell cover plate glue coating device includes a base 1, a power supply 2, a controller 3 and a rotating motor 4 are arranged inside the base 1, and the power supply 2, the controller 3 and the rotating motor 4 are all connected by lines. The output shaft 7 of the rotating motor 4 protrudes from the upper surface of the base 1, and the power capacitor positioning part 8 is connected above the output shaft 7, and a connecting seat 12 is also provided above the base 1, and the connecting seat 12 is sequentially connected with a fixed seat 15 and a storage material from bottom to top. Box 11, fixed seat 15 is connected with spring telescopic rod 16, and spring telescopic rod 16 is connected with gluing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com