A method and device for vibrating gluing

A kind of equipment and gluing technology, which is applied in the direction of adhesive application device, wood processing equipment, impregnated wood, etc., can solve the problems of uneven gluing, crack gluing and other problems, and achieve the effect of uniform gluing and improving yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be further understood through the specific examples of the present invention given below, but they are not intended to limit the present invention. Some non-essential improvements and adjustments made by those skilled in the art based on the above content of the invention are also deemed to fall within the protection scope of the present invention.

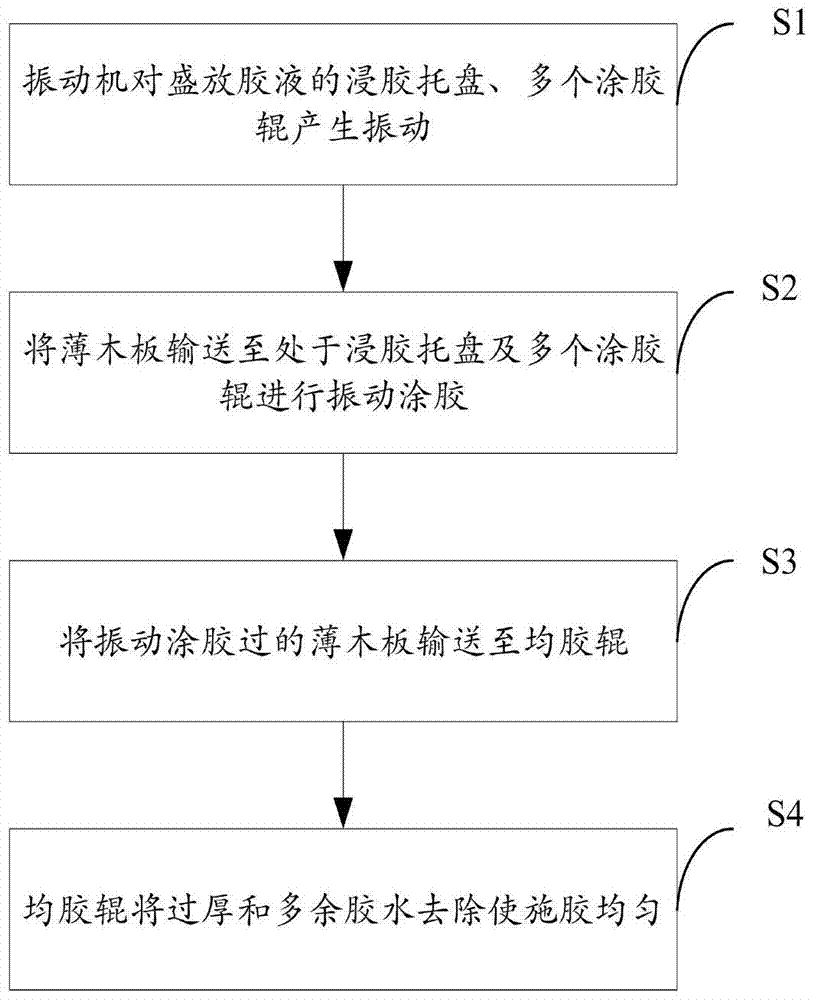

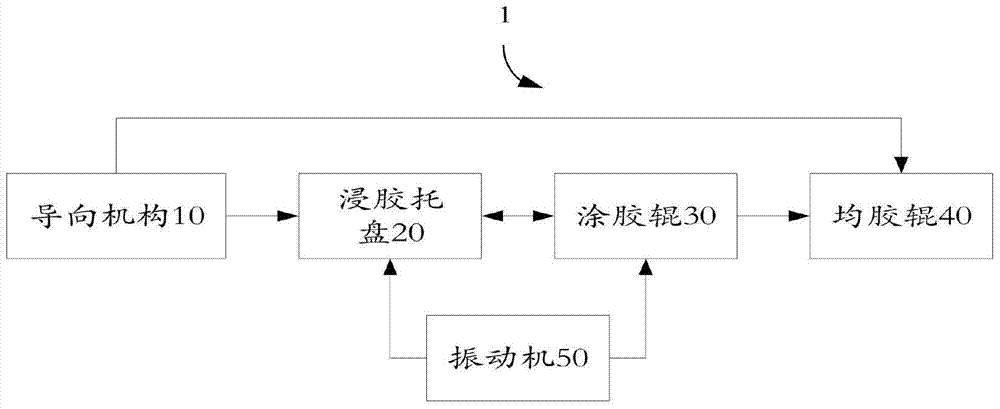

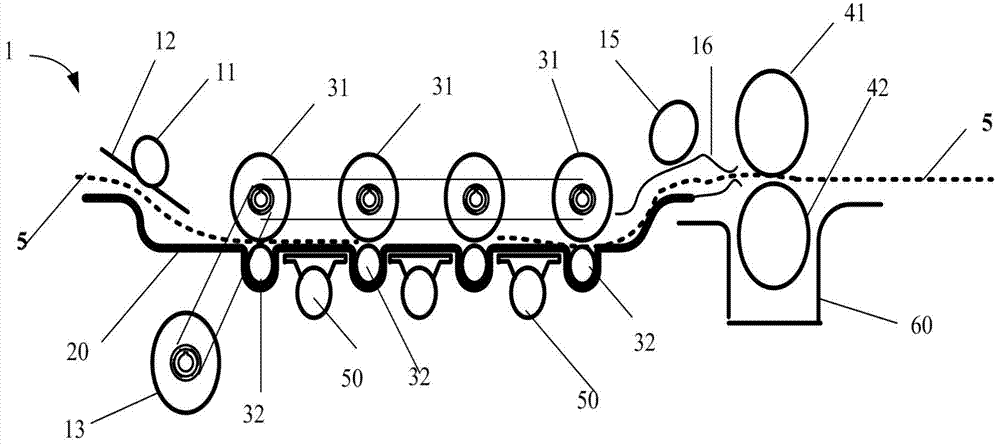

[0027] see figure 1 , a method for vibrating gluing, comprising:

[0028] S1. The vibrating machine vibrates the dipping tray and multiple gluing rollers containing the glue;

[0029] Preferably, the glue is made of veneer glue (also known as veneer glue), which is a white and uniform milky liquid with a solid content of about 50% and a pH value of about 5. It has high adhesive strength, no foaming, and veneer The surface is smooth and flat, high efficiency, even glue application, less glue application, can soften veneer, etc. Compared with all-purpose glue, it has the advantages of no blistering...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com