Absorbent material roller cutting equipment for CNC adult diaper production line

A technology for adult diapers and absorbent materials, applied in the field of absorbent material roller cutting equipment, can solve problems such as incomplete cutting, insufficient absorption, and short service life of cutting knives, so as to save downtime for maintenance and improve liquid absorption speed , The effect of reducing the frequency of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

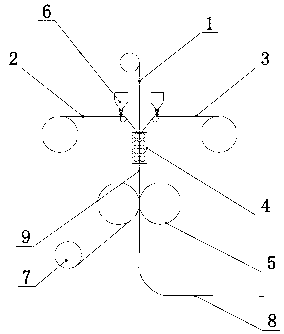

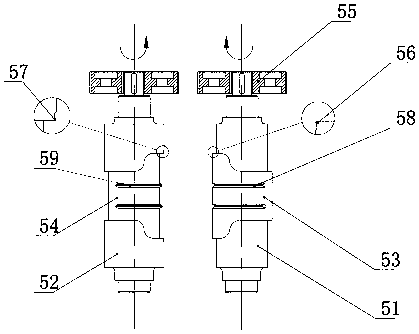

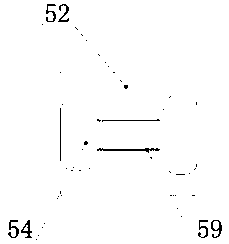

[0026] see Figure 1-Figure 7 , the present invention is a kind of absorbent material rolling cutting equipment of numerical control adult diaper production line, comprising absorbent core transmission unit, surface film transmission unit, base film transmission unit, hot glue pressing unit 4 and rolling cutting unit 5, said surface film transmission The discharge ends of the unit and the base film delivery unit are correspondingly provided with a glue spraying unit 6, and the absorbent core 1, the surface film 2, and the base film 3 delivered by the absorbent core delivery unit, the surface film delivery unit, and the base film delivery unit respectively pass through the heat The glue pressing unit 4 is bonded into the absorbent material 9 of the diaper, and the absorbent mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com