Composite plastic woven bag self-cleaning composite processing system and composite method thereof

A composite processing and composite plastic technology, which is applied in the direction of drying solid materials, lighting and heating equipment, progressive dryers, etc., can solve the problems of affecting the composite effect and unreliable glue, so as to improve the composite effect and ensure firm bonding degree, the effect of prolonging the contact time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

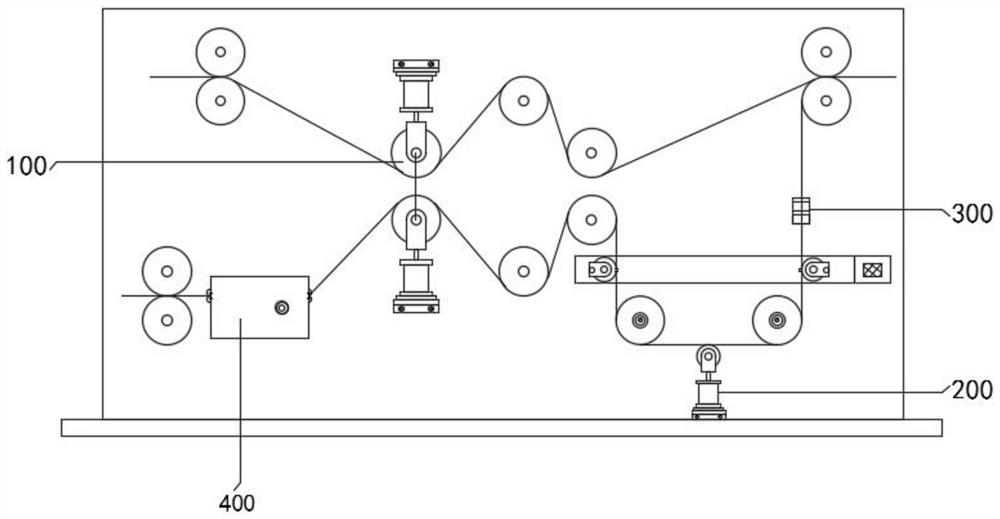

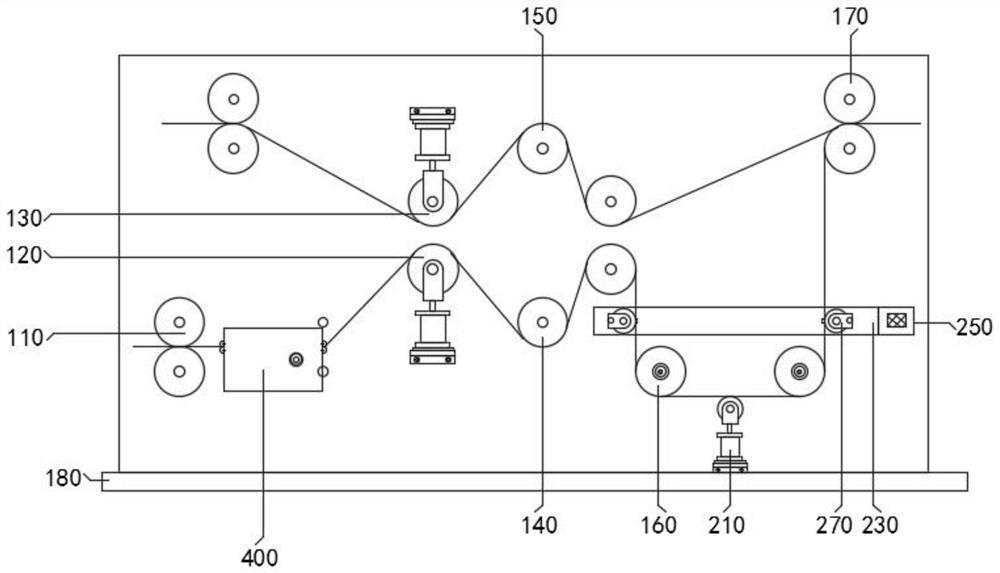

[0055] see Figure 1-10 , the present invention provides a composite plastic woven bag composite processing system, including a basic component 100 and an auxiliary glue application component 200 .

[0056] The basic assembly 100 includes a fixed frame 180, a feed roll set 110, a first dancer roll set 120, a second dancer roll set 130, a first guide roll set 140, a second guide roll set 150, a glue roll 160 and a pressing roll. Combined roller group 170, two feed roller groups 110 are all arranged on the fixed frame 180;

[0057] The auxiliary gluing assembly 200 includes a first driving member 210, a first limiting member 220, a fixed frame 230, a threaded rod 240, a second driving member 250, a threaded sleeve 260 and a second limiting member 270;

[0058] A processing box 400 is installed on the fixed frame on one side of the feed roller group, and the two sides of the processing box 400 are respectively equipped with feeding and discharging nip rollers 401, and the interi...

Embodiment 2

[0062] see Figure 1-10 , the present invention provides a composite plastic woven bag composite processing system, including a basic component 100 and an auxiliary glue application component 200 .

[0063]The basic assembly 100 includes a fixed frame 180, a feed roll set 110, a first dancer roll set 120, a second dancer roll set 130, a first guide roll set 140, a second guide roll set 150, a glue roll 160 and a pressing roll. Combined roller group 170, two feed roller groups 110 are all arranged on the fixed frame 180;

[0064] The auxiliary gluing assembly 200 includes a first driving member 210, a first limiting member 220, a fixed frame 230, a threaded rod 240, a second driving member 250, a threaded sleeve 260 and a second limiting member 270;

[0065] A processing box 400 is installed on the fixed frame on one side of the feed roller group, and the two sides of the processing box 400 are respectively equipped with feeding and discharging nip rollers 401, and the interio...

Embodiment 3

[0070] see Figure 1-8 The auxiliary gluing component 200 is arranged on the basic component 100, which can increase the contact area between the gluing surface of the plastic woven film material belt and the surface of the gluing mechanism, prolong the contact time with the gluing mechanism, and ensure the gluing effect.

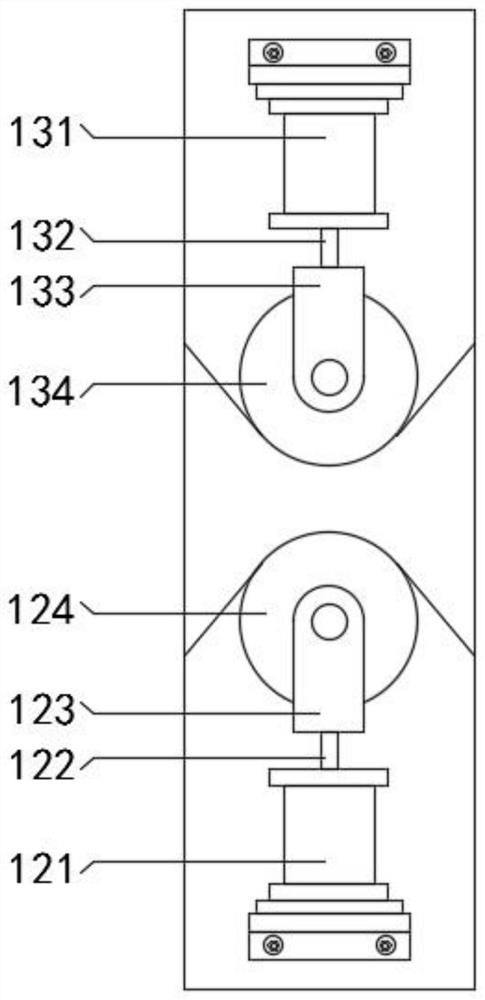

[0071] see Figure 2-6 , the basic assembly 100 includes a fixed frame 180, a feed roller group 110, a first dancer roller group 120, a second dancer roller group 130, a first guide roller group 140, a second guide roller group 150, a glue roller 160 and Pressing roller group 170, two feed roller groups 110 are all arranged on the fixed frame 180, the first guide roller group 140 and the second guide roller group 150 are all arranged on the fixed frame 180, the first elastic adjustment roller group 120 and The second dancer roller group 130 is all arranged on the fixed frame 180, and the first dancer roller group 120 is located between the feed roller grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com