An automatic glue injection equipment when producing led lights

A technology of LED lamp and glue injection, which is applied to the device and coating of the surface coating liquid, which can solve the problems of low work efficiency and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

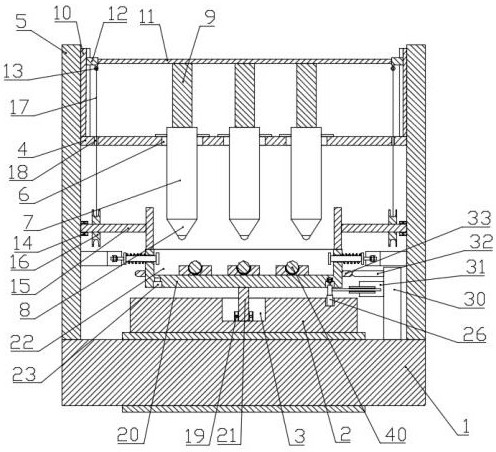

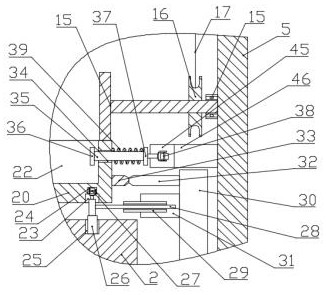

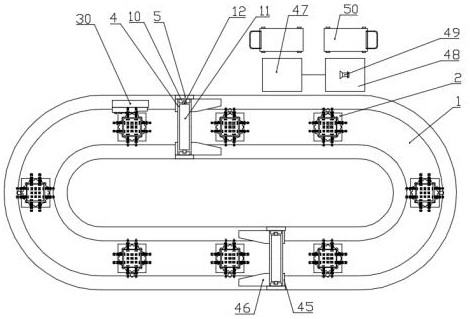

[0024] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-6 shown.

[0025] In this embodiment, this device can install a suitable number of automatic glue injection mechanisms on the rotary conveyor 1 according to actual needs, and the glue injection syringes 7 can be placed according to the actual number of needs.

[0026] The invention point of the application lies in the structural design of the automatic glue injection mechanism. figure 1 And attached image 3 , the automatic glue injection mechanism includes a plurality of fixed tables 2 fixedly installed on the upper surface of the rotary conveyor belt 1, the fixed table 2 is provided with a holding hole 3, and the top of the rotary conveyor belt 1 is provided with a holding plate 4, and the two sides of the holding plate 4 are A support plate 5 is installed, the lower end of the support plate 5 is fixedly installed on the rotary conveyor belt 1, the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com