Viton synthetic rubber joints

A synthetic rubber and fluororubber technology, applied in the direction of pipes/pipe joints/fittings, adjustable connections, mechanical equipment, etc., can solve the problems of easy fatigue, oxidation, short service life, pollute the environment, etc. Excellent performance and high strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

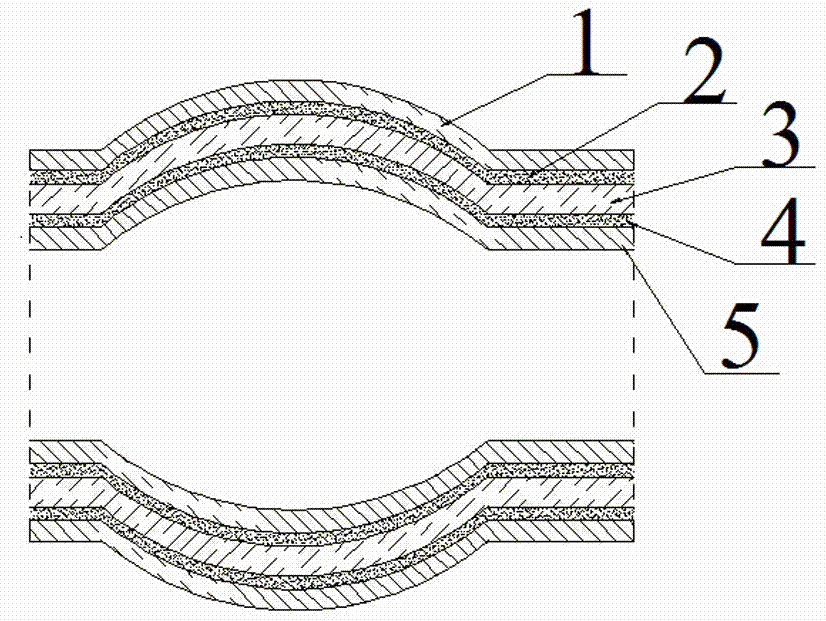

[0048] A fluorine rubber synthetic rubber joint, see figure 1 , the pipe wall includes an outer rubber outer layer, an outer rubber inner layer, a composite skeleton layer, an inner rubber inner layer and an inner rubber outer layer from the outside to the inside in turn, and each layer of the pipe wall is made of raw materials in the following proportions:

[0049] The outer layer of the outer rubber is in contact with the outside air and is composed of the following raw materials in parts by weight: 1.8 parts of anti-aging agent, 4.5 parts of fluororubber, 2.5 parts of natural rubber, 0.5 part of vulcanizing agent, and 1.0 part of accelerator; the inner layer of the outer rubber is composed of The following raw materials are composed of parts by weight: 0.5 parts of vulcanizing agent, 1.0 part of accelerator, 5 parts of fluororubber, 2.5 parts of natural rubber, and 1.3 parts of carbon black; The inner rubber inner layer is composed of the following raw materials in parts by...

Embodiment 2

[0053] A fluorine rubber synthetic rubber joint, the pipe wall comprises an outer rubber outer layer, an outer rubber inner layer, a composite skeleton layer, an inner rubber inner layer and an inner rubber outer layer sequentially from the outside to the inside, and each layer of the pipe wall consists of the following Ratio of ingredients made from:

[0054] The outer layer of the outer rubber is in contact with the outside air, and is composed of the following raw materials in parts by weight: 0.5 parts of anti-aging agent, 3 parts of fluororubber, 1 part of natural rubber, 0.2 part of vulcanizing agent, and 0.5 part of accelerator; the inner layer of the outer rubber is composed of The following raw materials are composed of parts by weight: 0.2 part of vulcanizing agent, 0.5 part of accelerator, 2 parts of fluororubber, 1 part of natural rubber, and 0.8 part of carbon black; The inner rubber inner layer is composed of the following raw materials in parts by weight: 0.2 pa...

Embodiment 3

[0058] A fluorine rubber synthetic rubber joint, the pipe wall comprises an outer rubber outer layer, an outer rubber inner layer, a composite skeleton layer, an inner rubber inner layer and an inner rubber outer layer sequentially from the outside to the inside, and each layer of the pipe wall consists of the following Ratio of ingredients made from:

[0059] The outer layer of the outer rubber is in contact with the outside air and is composed of the following raw materials in parts by weight: 3 parts of anti-aging agent, 6 parts of fluororubber, 4 parts of natural rubber, 0.8 part of vulcanizing agent, and 1.5 parts of accelerator; the inner layer of the outer rubber is composed of The following raw materials are composed of parts by weight: 0.8 parts of vulcanizing agent, 1.5 parts of accelerator, 8 parts of fluororubber, 4 parts of natural rubber, and 1.8 parts of carbon black; The inner rubber inner layer is composed of the following raw materials in parts by weight: 0.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com