A gluing device for bamboo canes

A technology of gluing and bamboo strips, which is applied in the direction of adhesive applying devices, wood processing appliances, manufacturing tools, etc., can solve the problems of shortened service life, scattered bamboo strips, lack of toughness, etc., and achieve long service life, sufficient gluing, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with examples, which are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

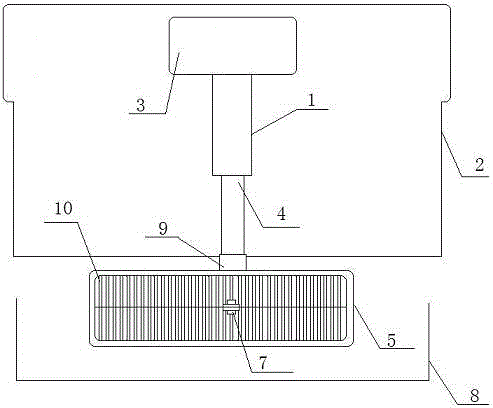

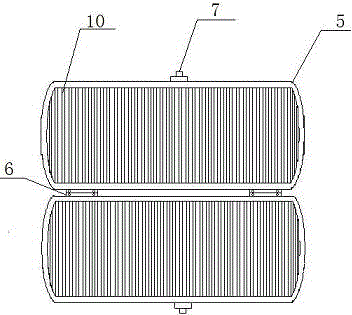

[0014] This example figure 1 and figure 2 Shown: a gluing device for bamboo strips, including a cylinder 1, a main support 2 and a motor 3, the main support 2 is provided with a motor 3, the lower part of the motor 3 is connected to the cylinder 1, and the lower part of the cylinder 1 Connect the stirring arm 4, the bottom of the stirring arm 4 is connected with the cylindrical stirring wheel 5, the inner upper part and the lower part of the stirring wheel 5 are respectively provided with hinges 6 that are convenient to be opened from the inside, and the outer upper part and the lower part of the stirring wheel 5 are respectively An elastic bolt 7 is provided, and a glue pool 8 is place...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com